Publication 1756-RM014B-EN-P - November 2023

Supersedes Publication 1756-RM014A-EN-P - March 2022

Reference Manual

Original Instructions

Logix 5000 Controllers

Import/Export

1756 ControlLogix, 1756 GuardLogix, 1769 CompactLogix,

1769 Compact GuardLogix, 1789 SoftLogix, 5069

CompactLogix, 5069 Compact GuardLogix, Studio 5000

Logix Emulate

Logix 5000 Controllers Import/Export

2 Publication 1756-RM014B-EN-P - November 2023

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to familiarize

themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws, and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required to

be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use

or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING:

Identifies information about practices or circumstances that can cause an explosion in a hazardous environment, which may lead to

personal injury or death, property damage, or economic loss.

ATTENTION:

Identifies information about practices or circumstances that can lead to personal injury or death, property damage, or economic loss.

Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

IMPORTANT

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous voltage may be present.

BURN HAZARD:

Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may reach dangerous

temperatures.

ARC FLASH HAZARD:

Labels may be on or inside the equipment, for example, a motor control center, to alert people to potential Arc Flash. Arc Flash will

cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL Regulatory requirements for safe work practices and for

Personal Protective Equipment (PPE).

Rockwell Automation recognizes that some of the terms that are currently used in our industry and in this publication are not in

alignment with the movement toward inclusive language in technology. We are proactively collaborating with industry peers to

find alternatives to such terms and making changes to our products and content. Please excuse the use of such terms in our

content while we implement these changes.

Publication 1756-RM014B-EN-P - November 2023 3

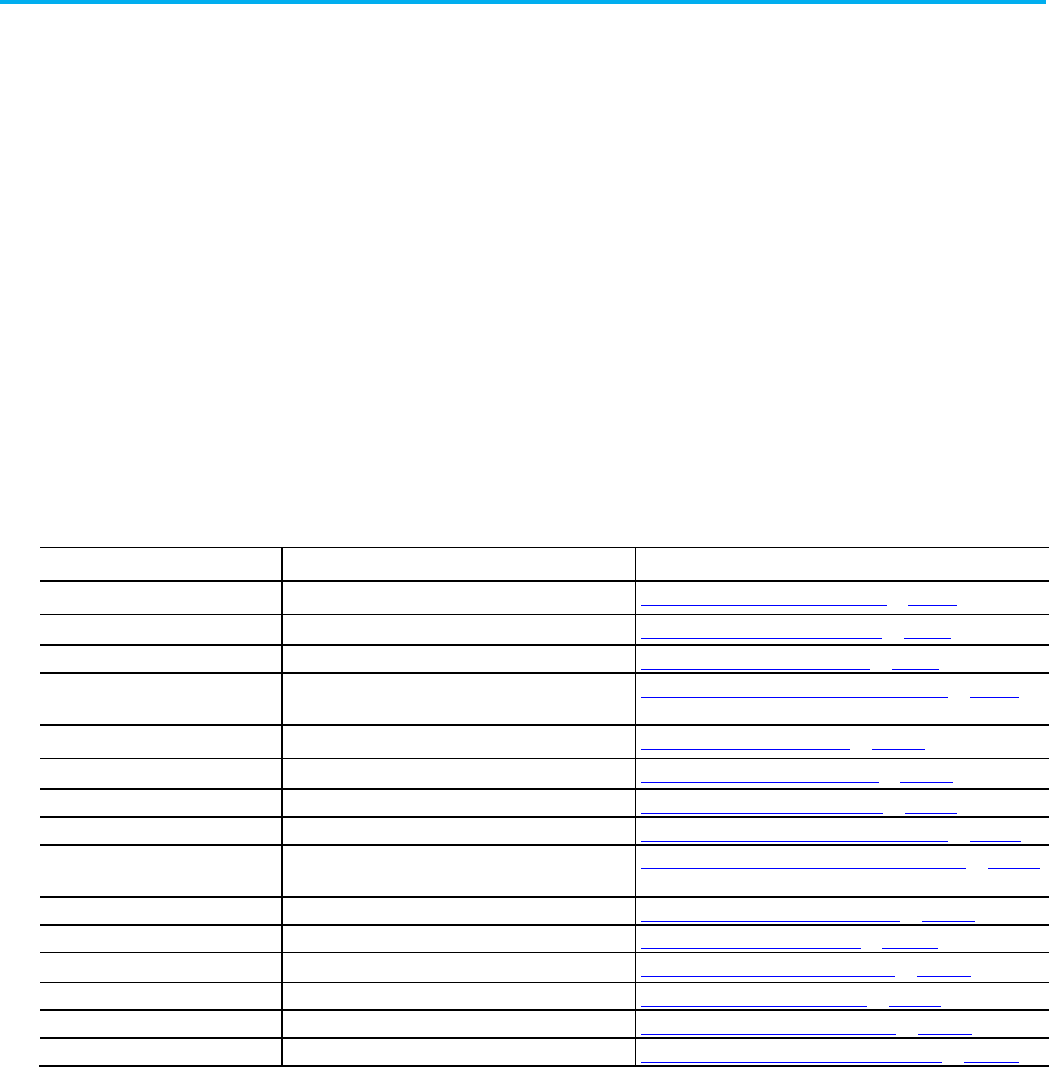

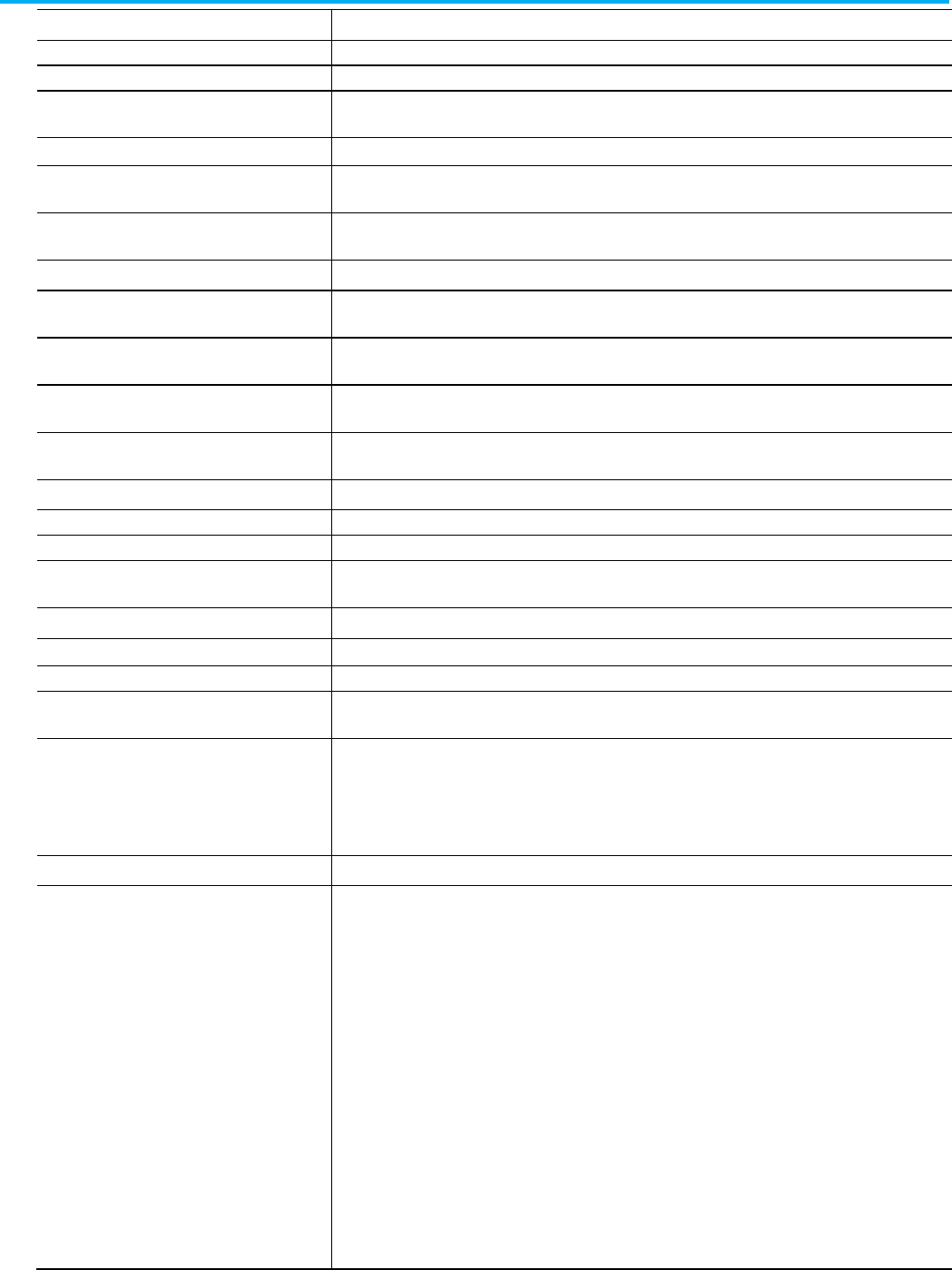

Summary of changes

This manual includes new and updated information. Use these reference

tables to locate changed information.

Grammatical and editorial style changes are not included in this summary.

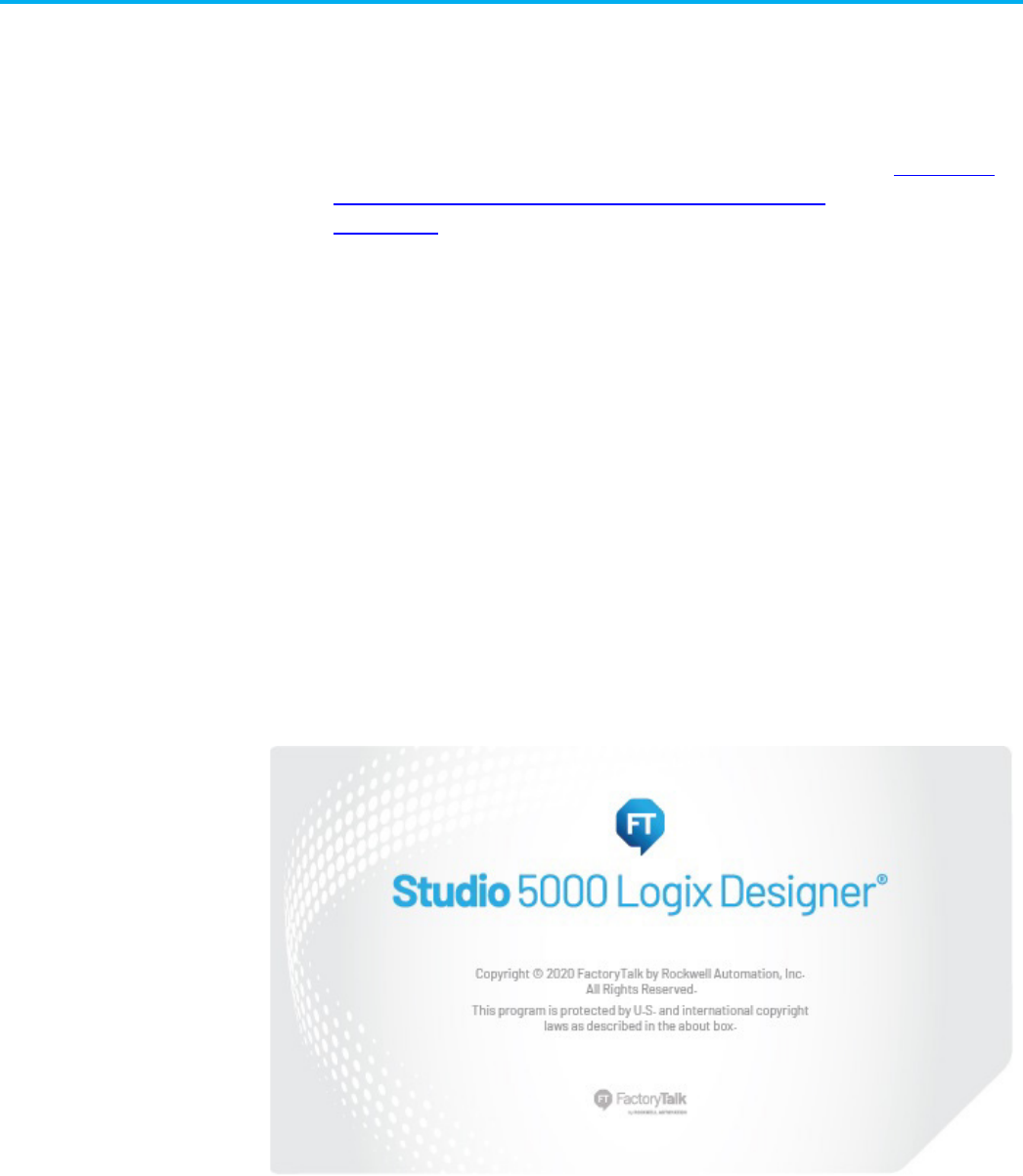

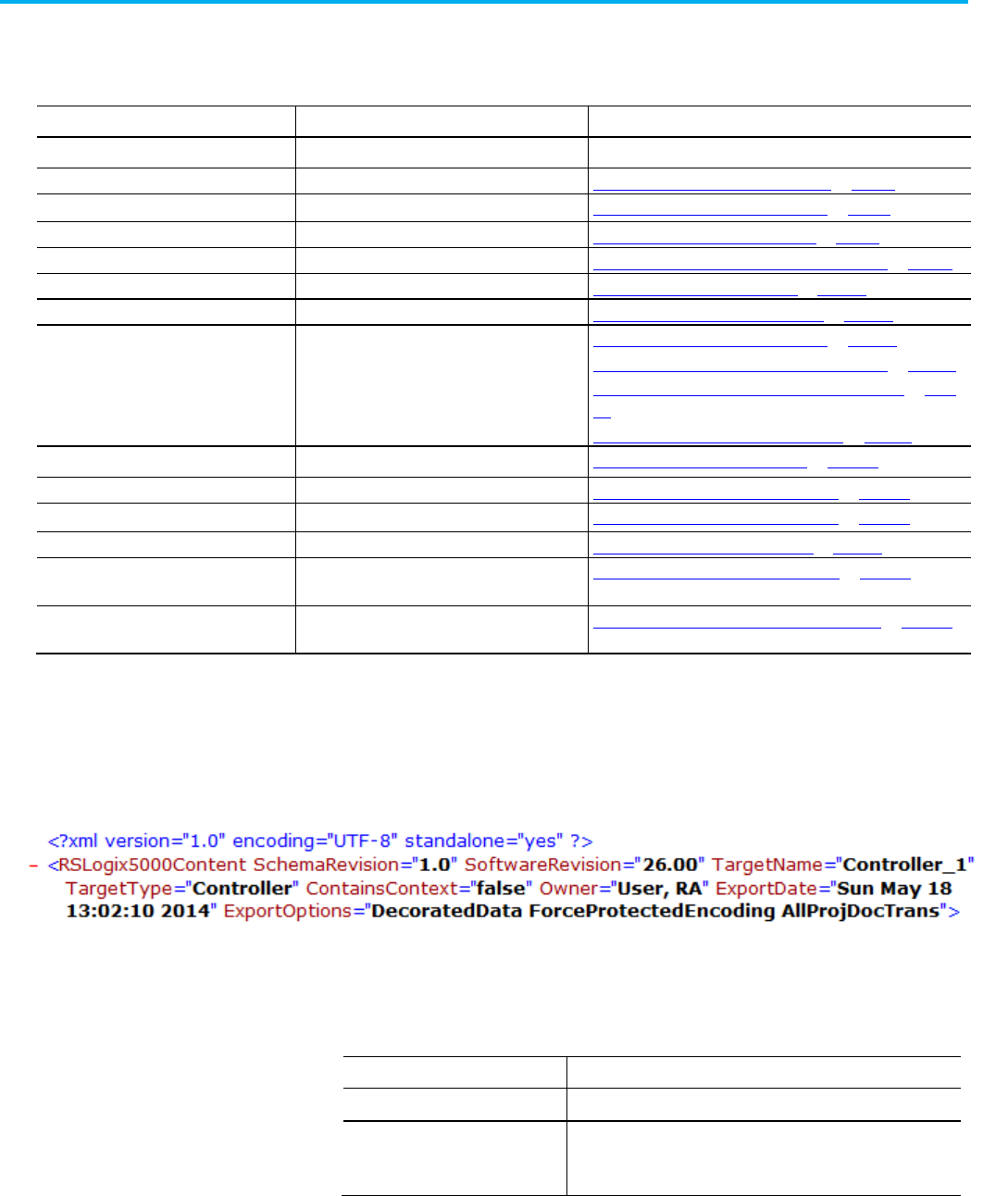

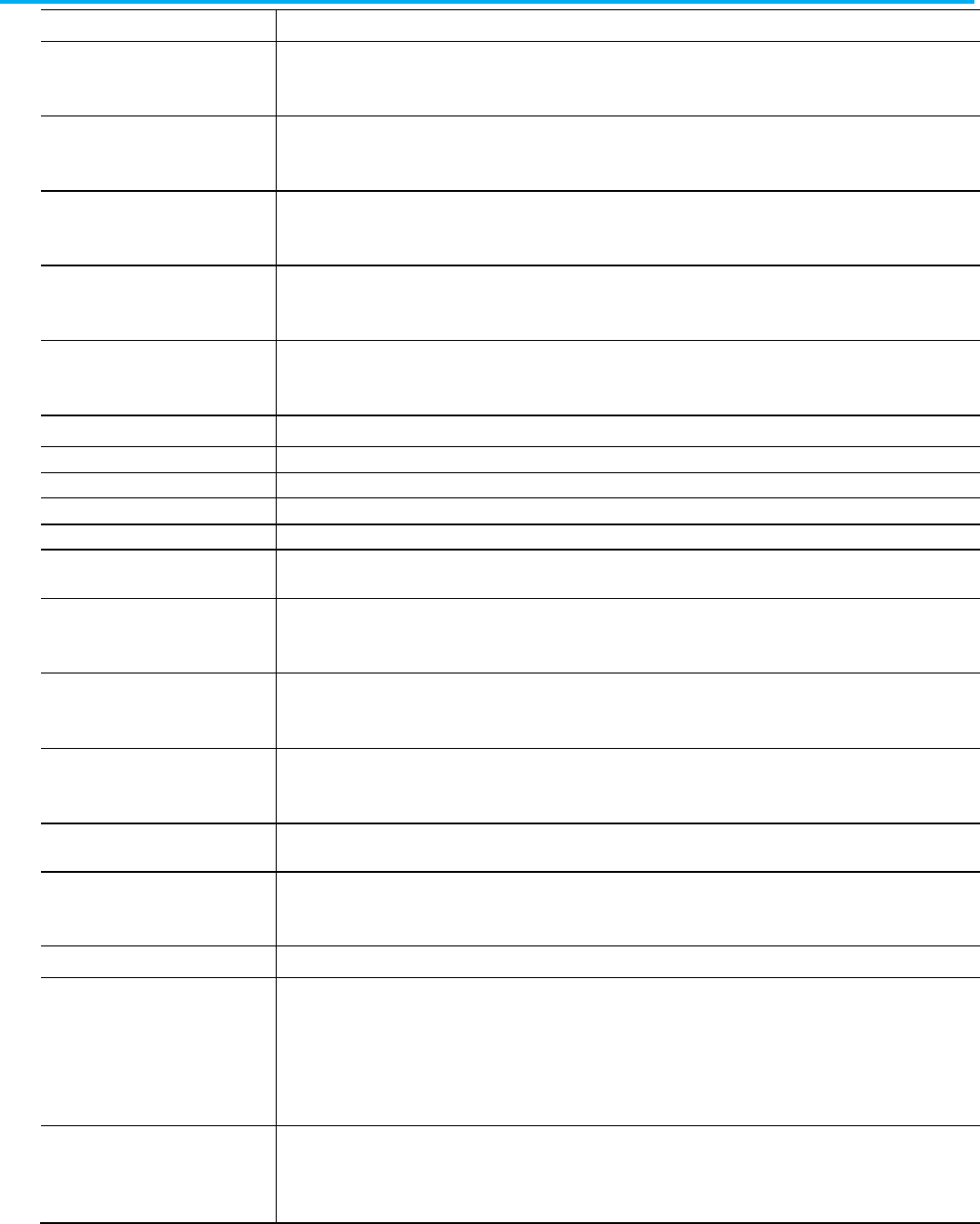

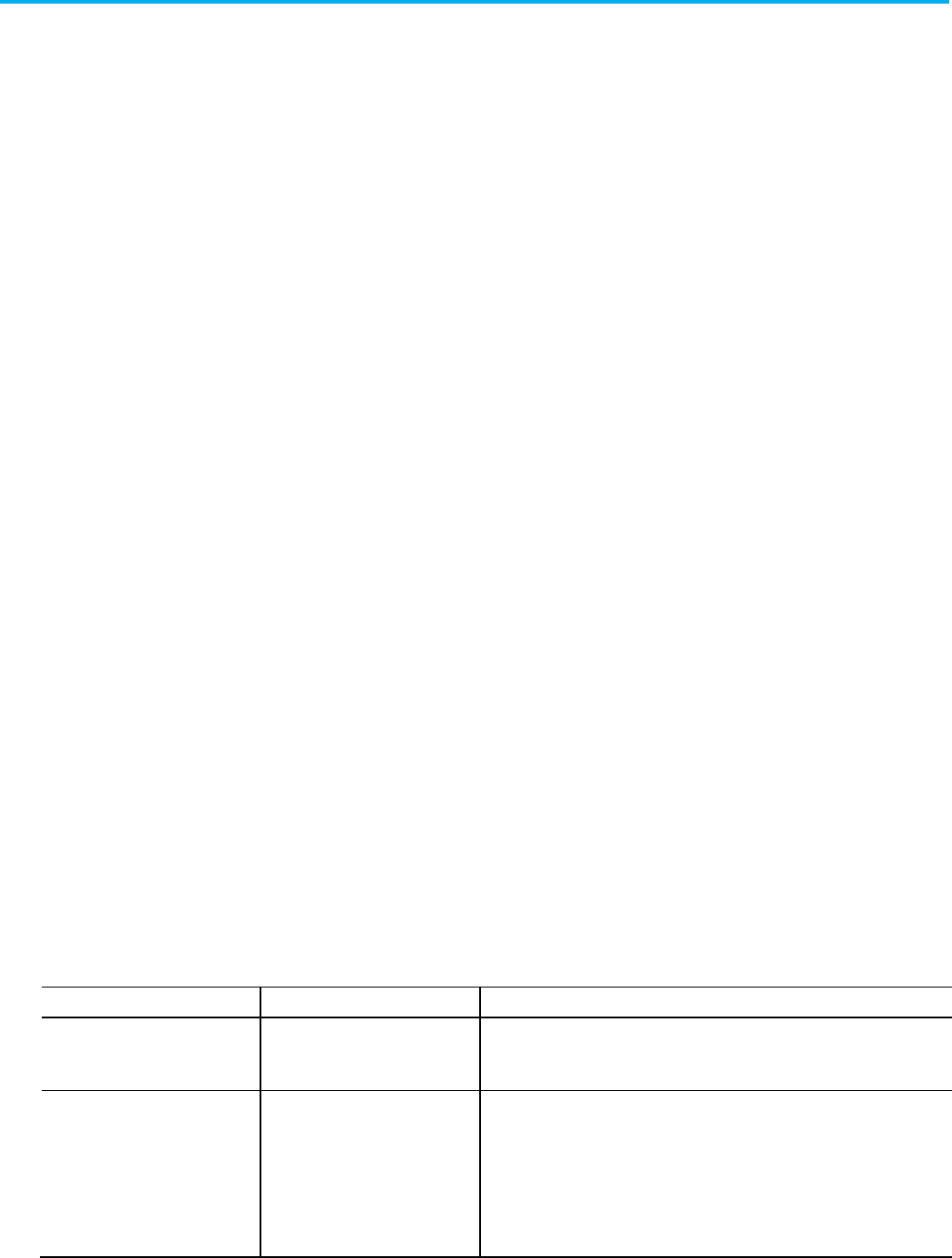

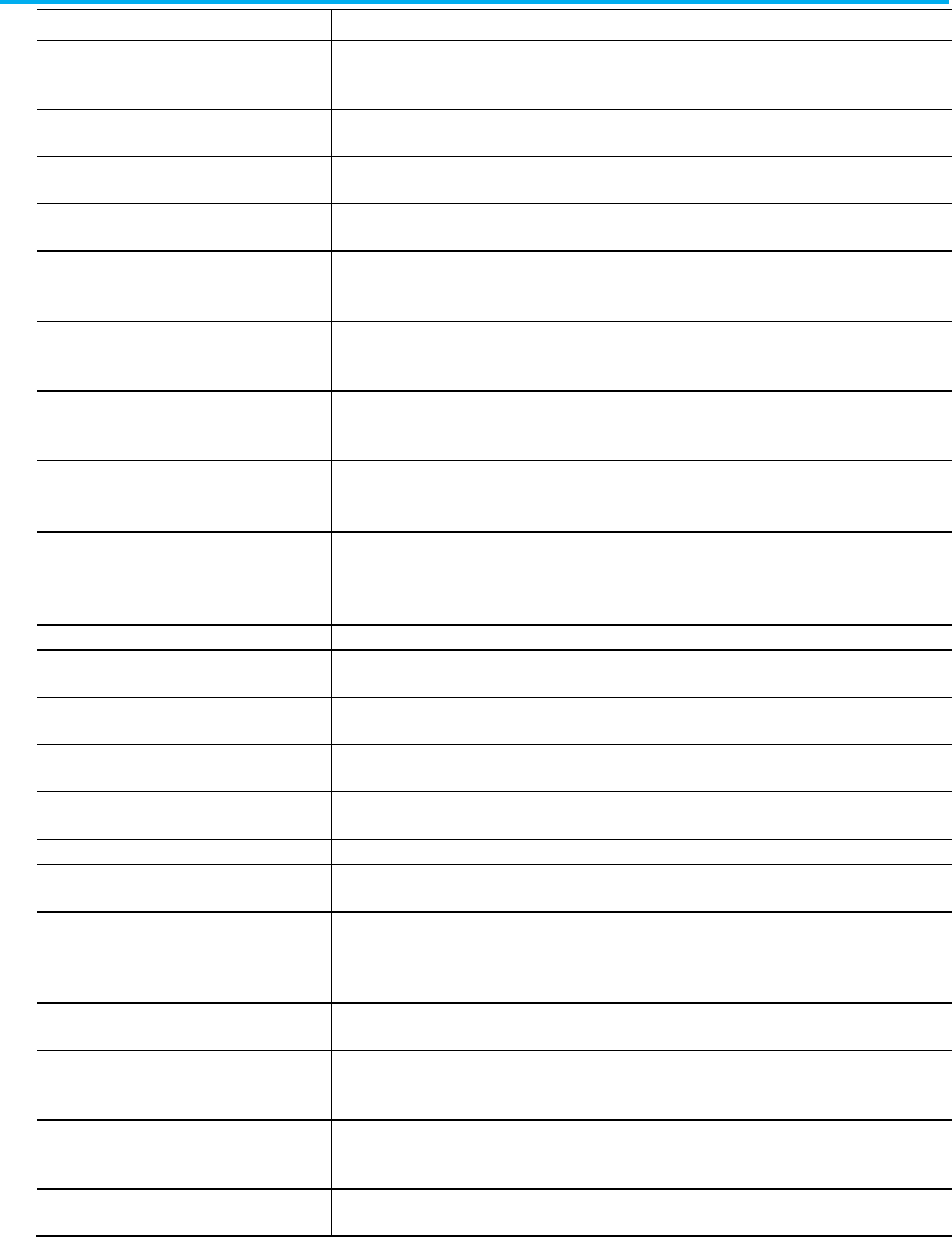

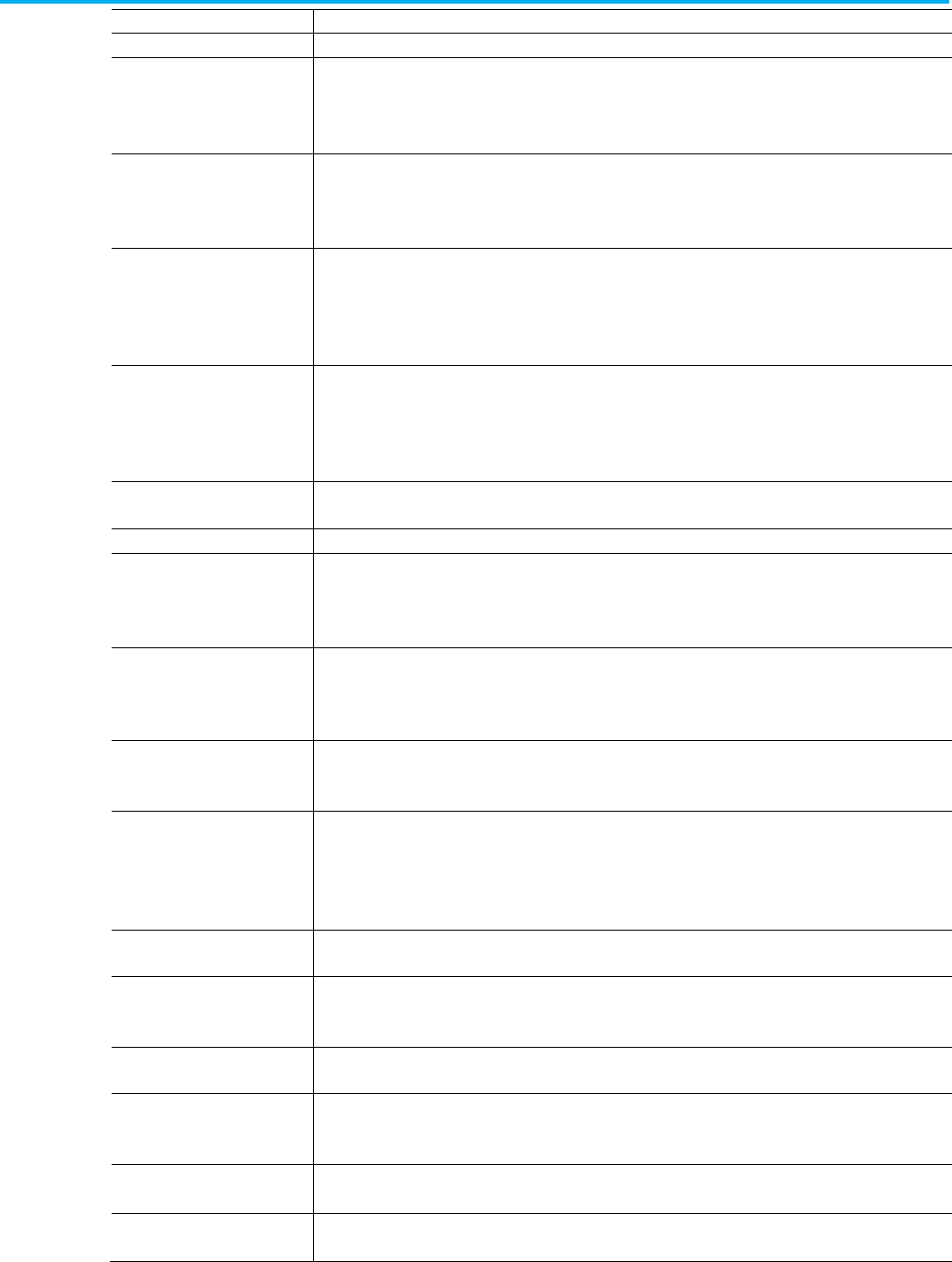

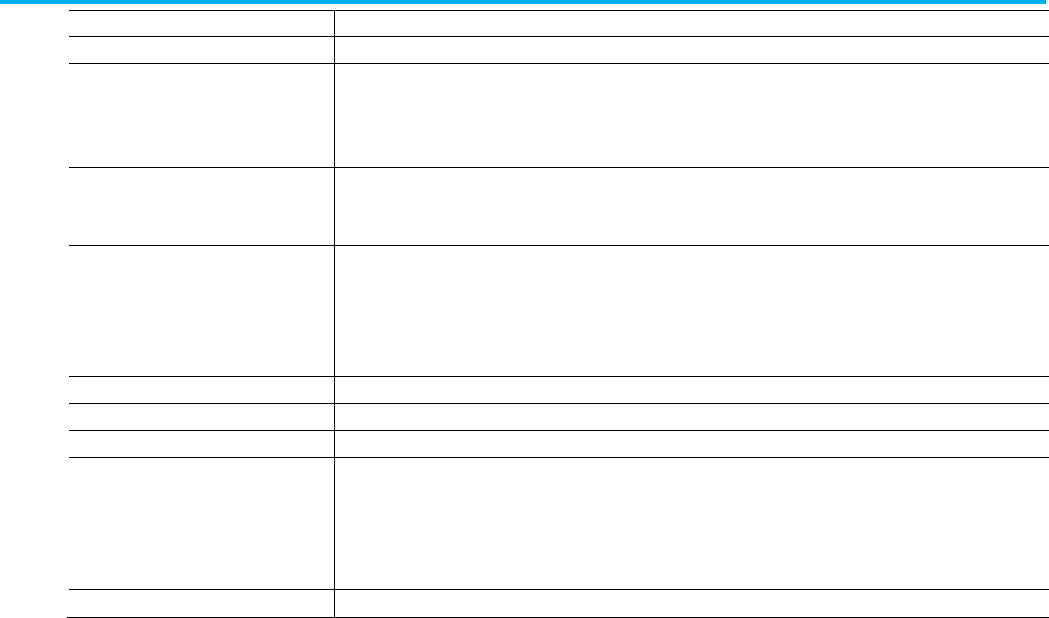

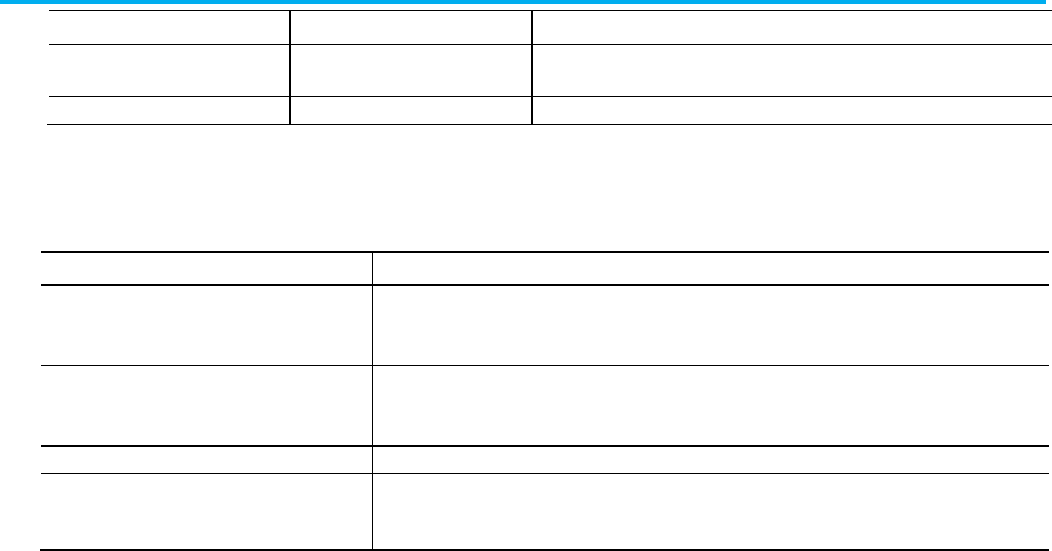

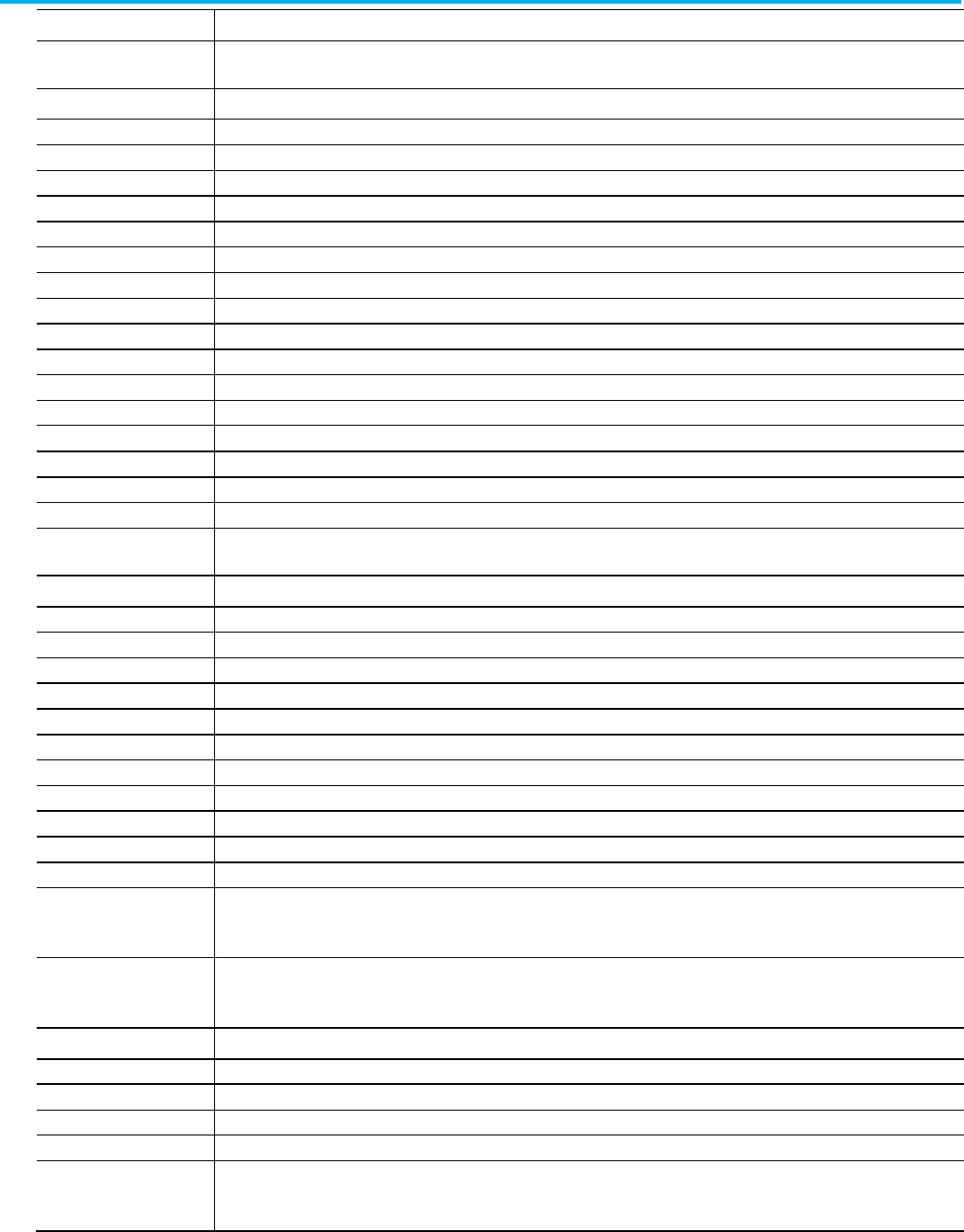

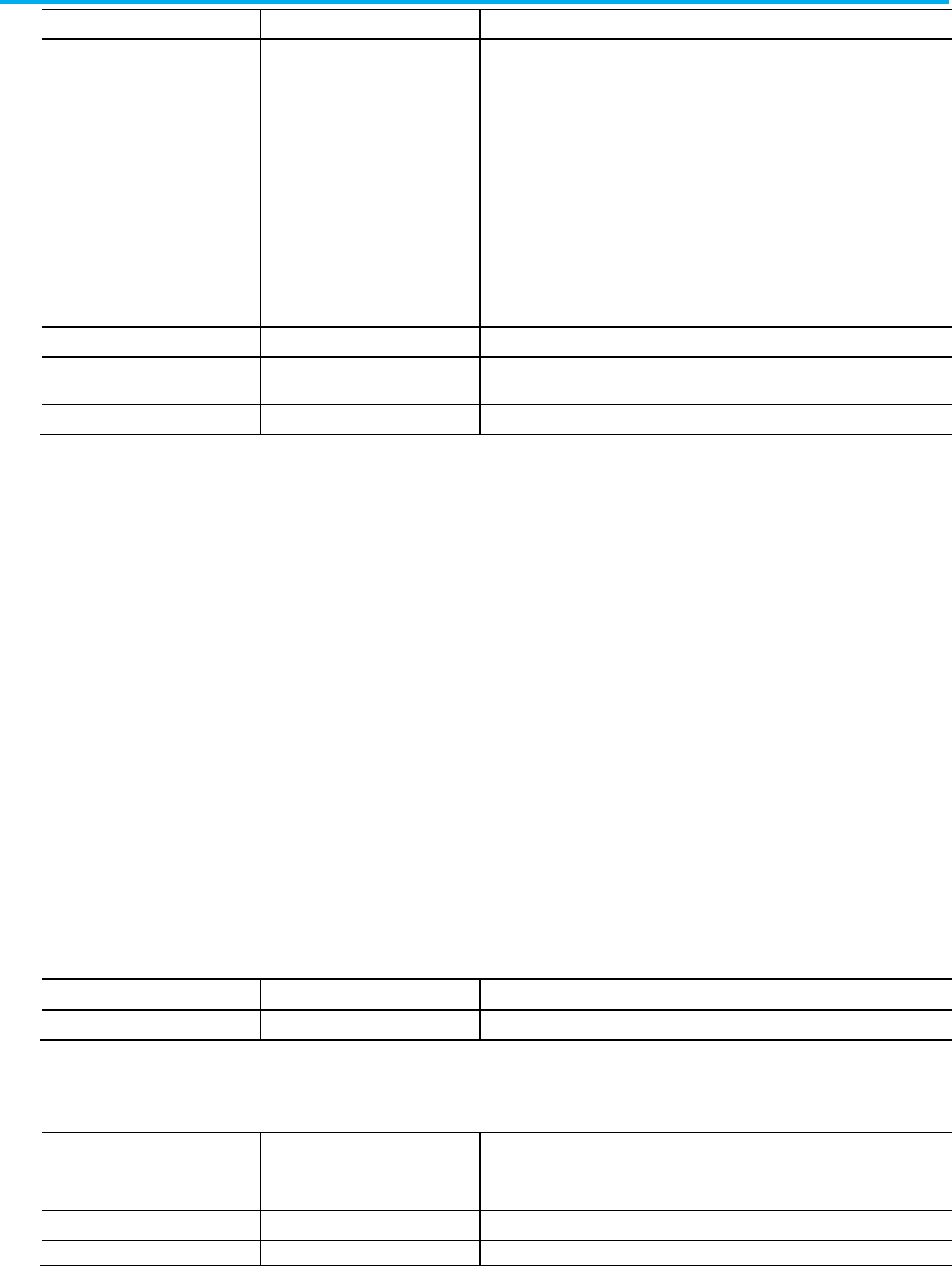

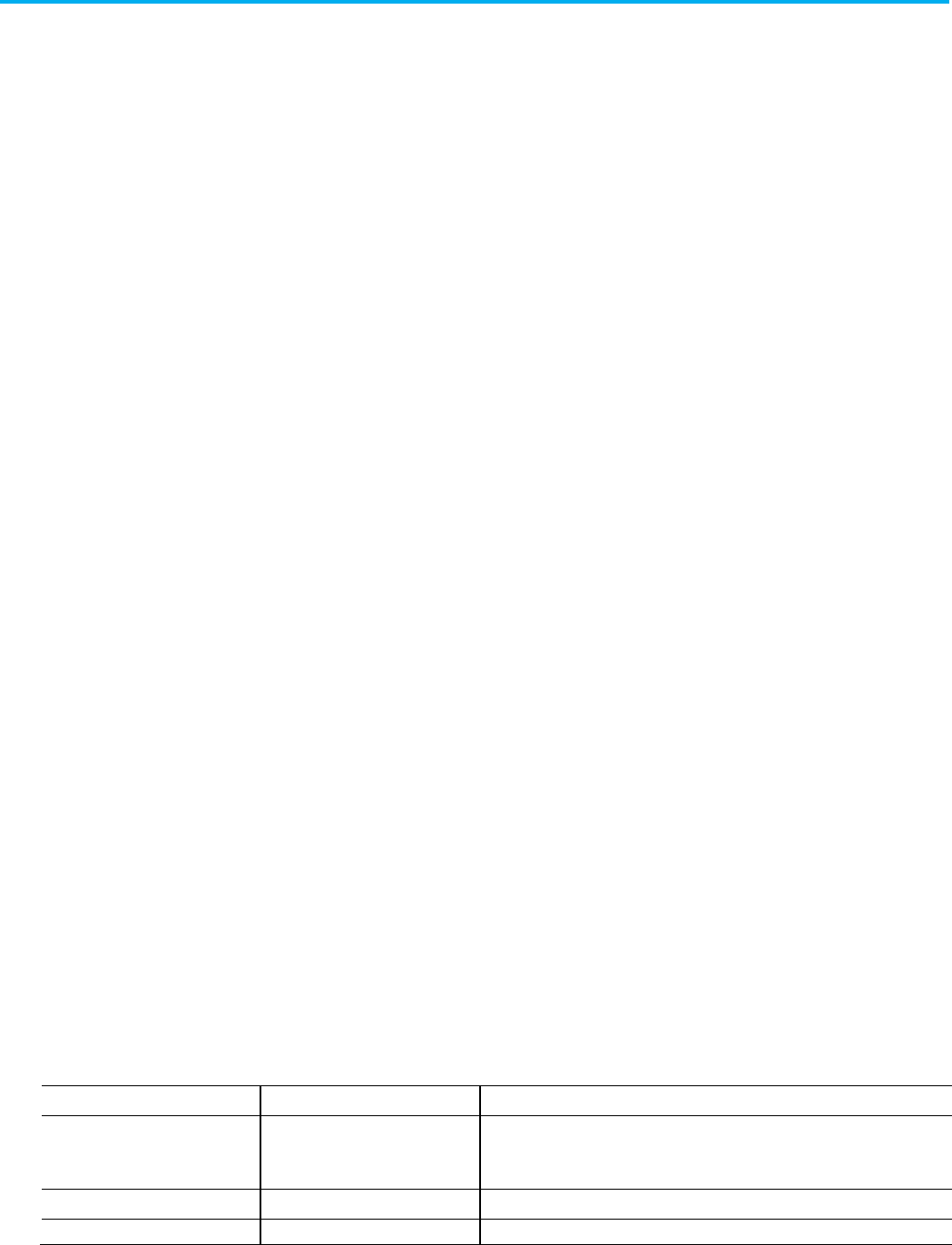

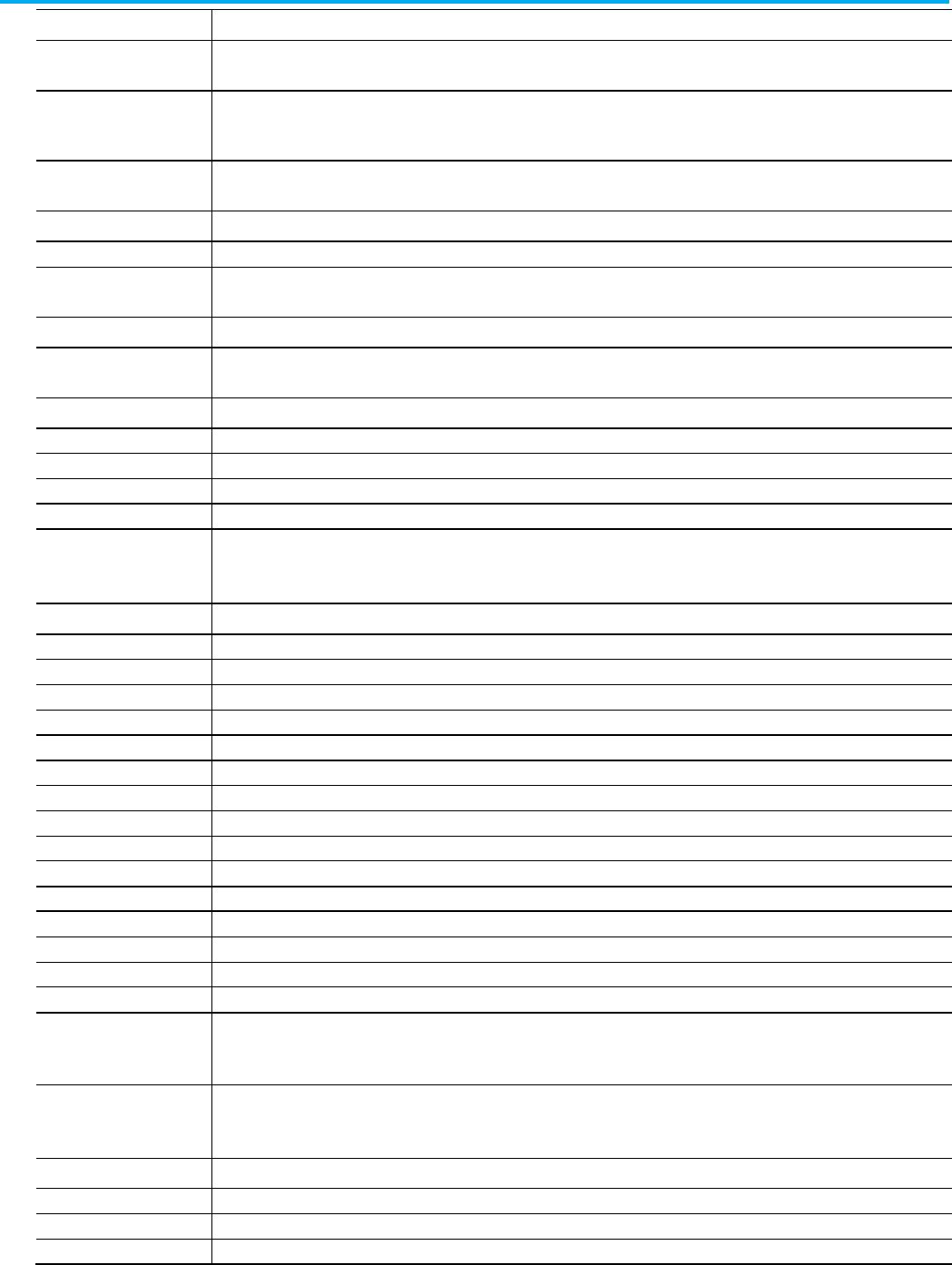

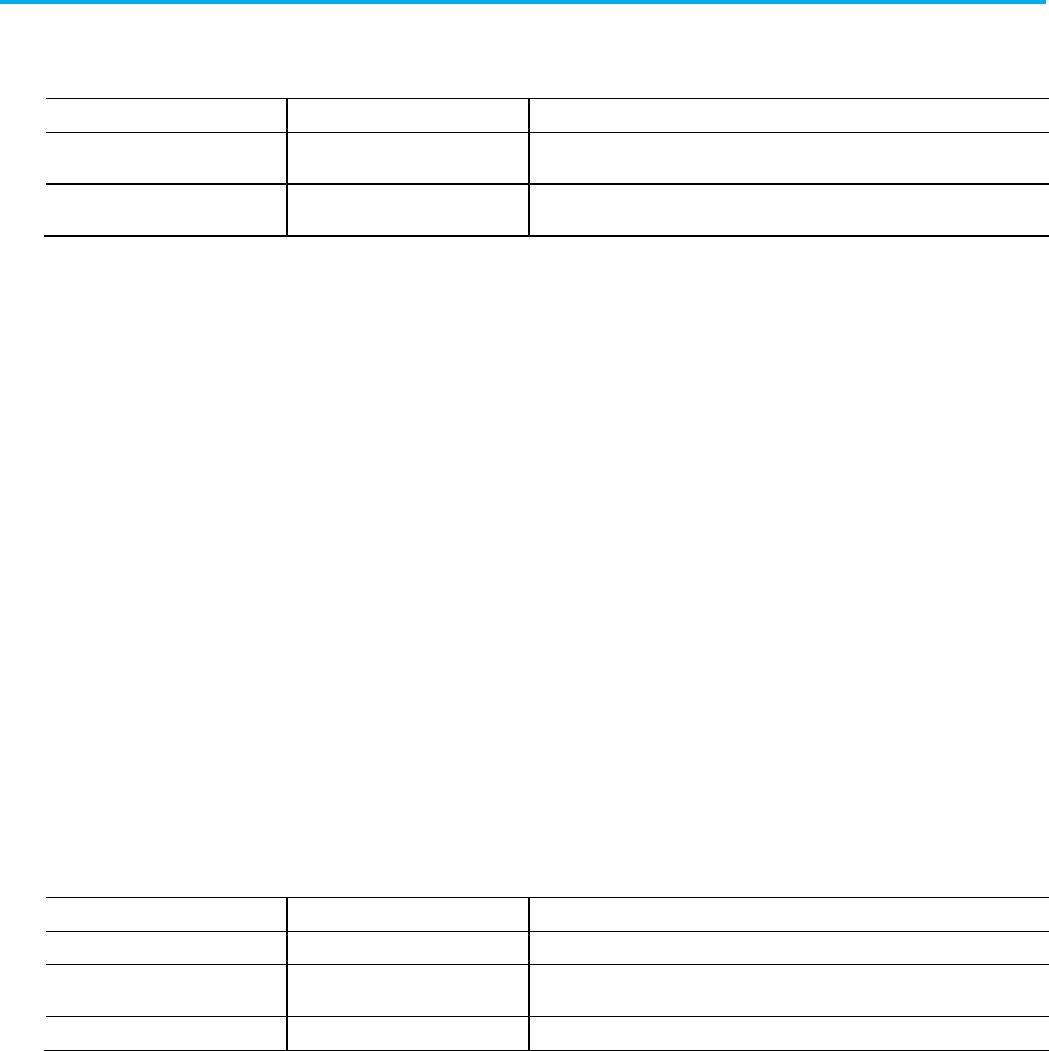

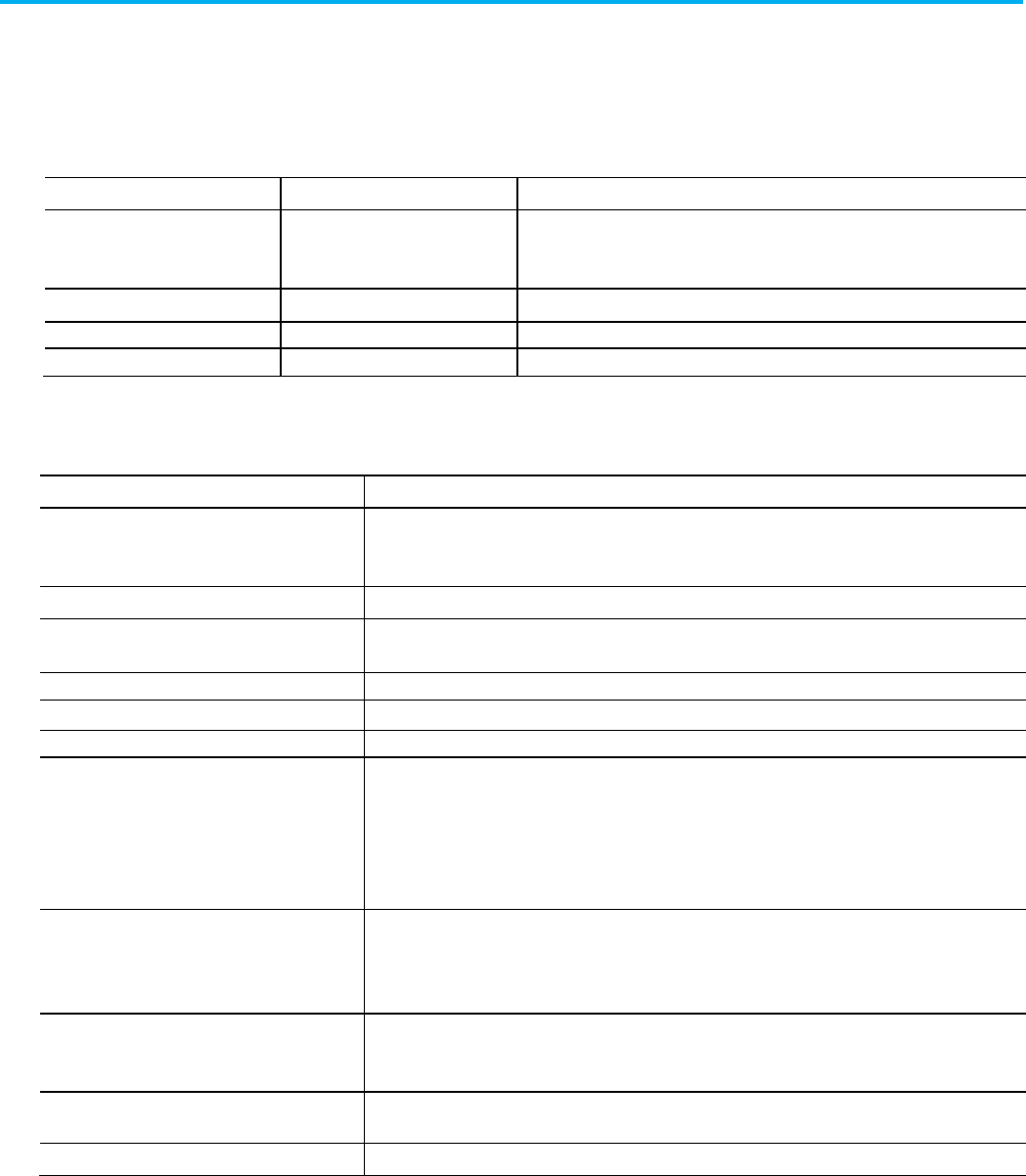

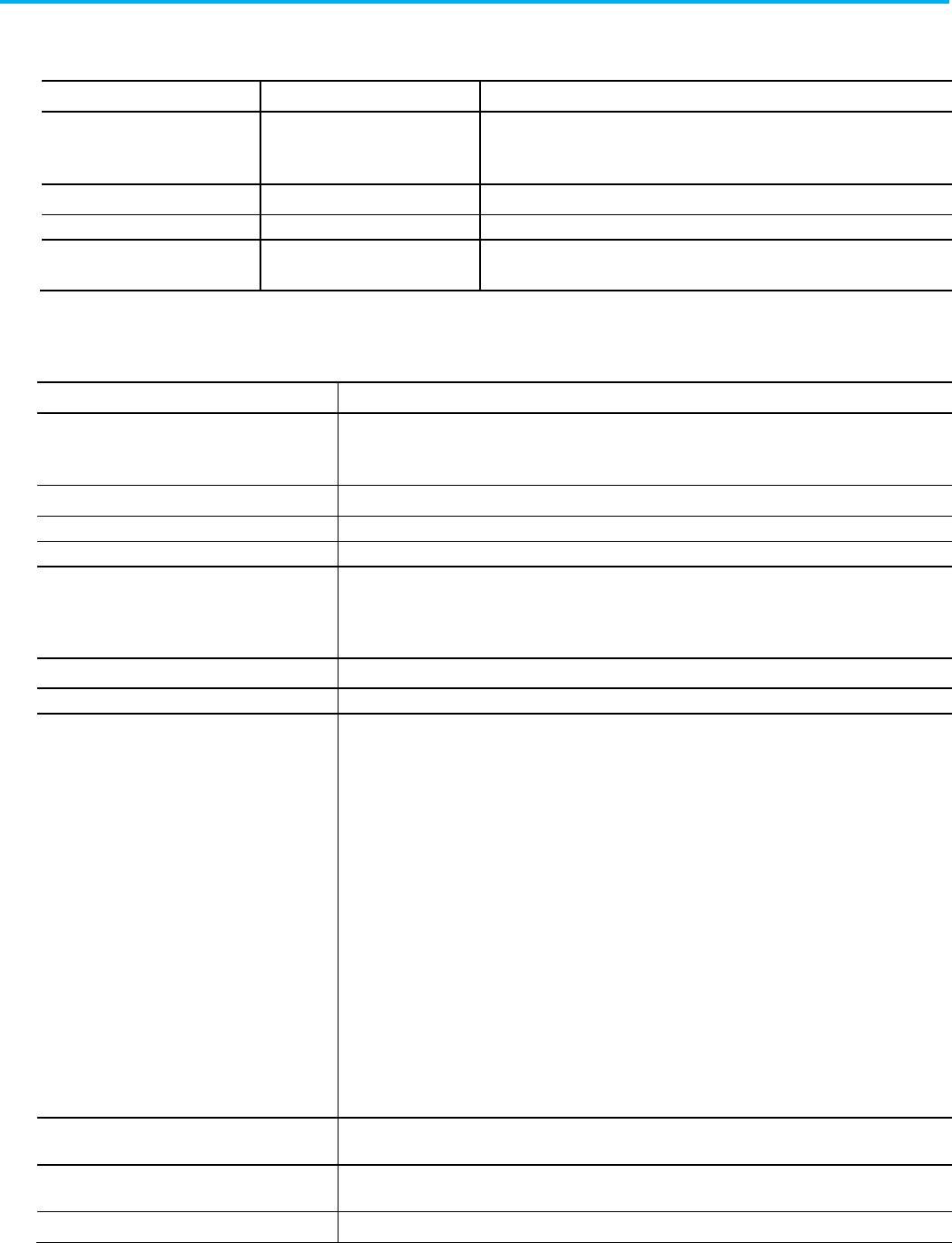

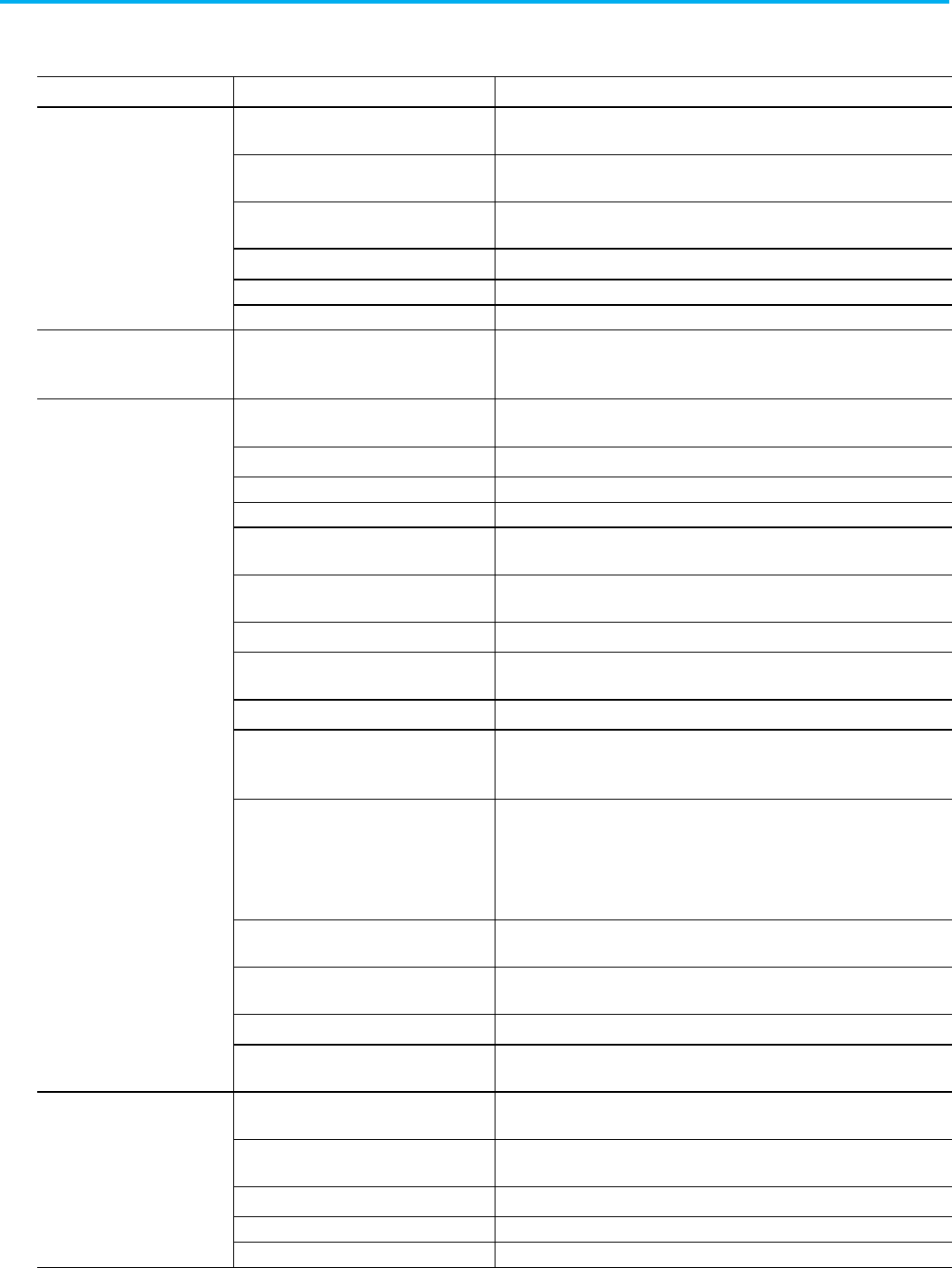

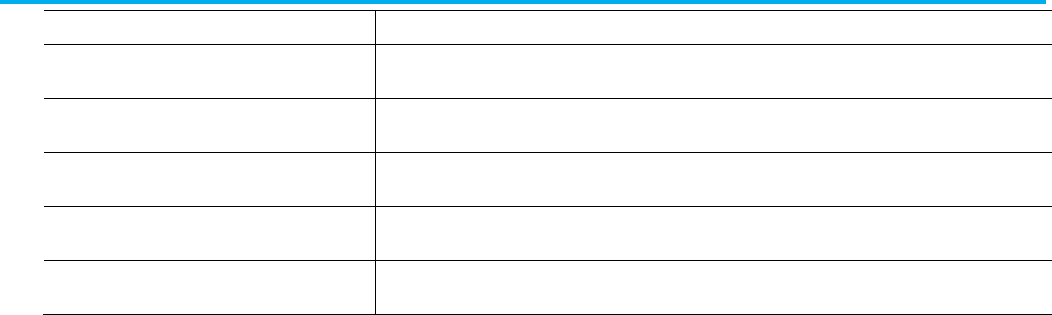

Global changes

This table identifies changes that apply to all information about a subject in

the manual and the reason for the change. For example, the addition of new

supported hardware, a software design change, or additional reference

material would result in changes to all of the topics that deal with that subject.

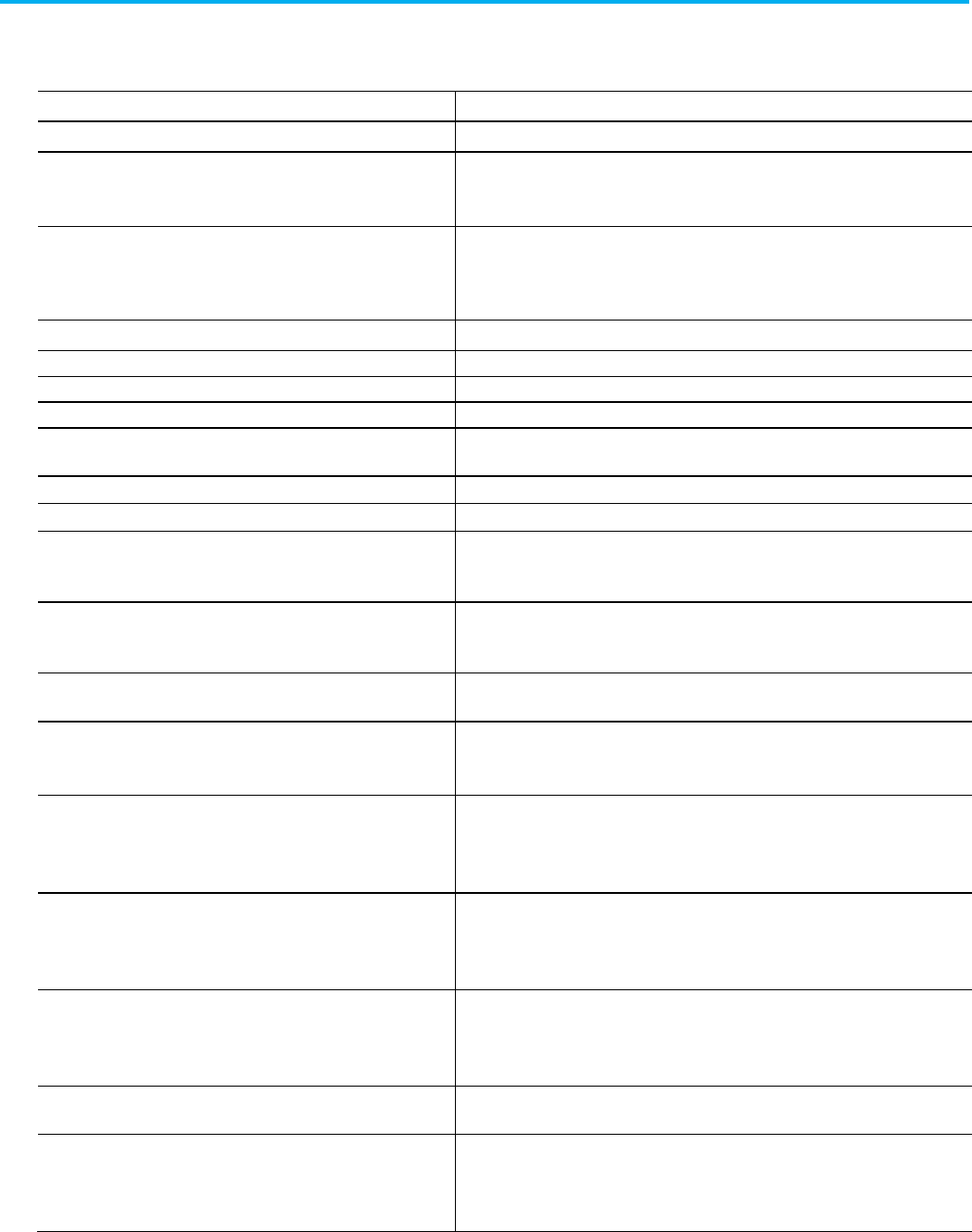

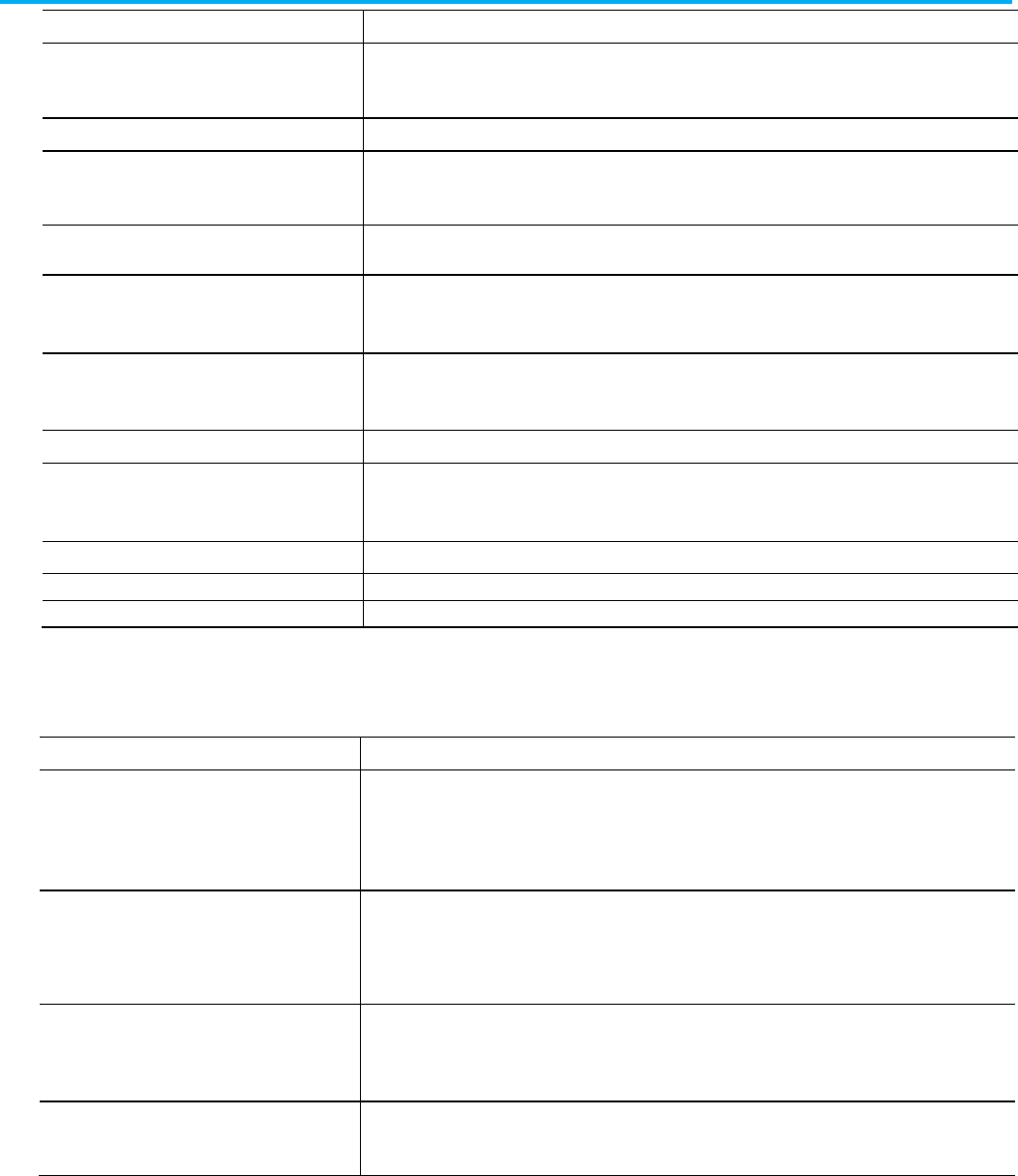

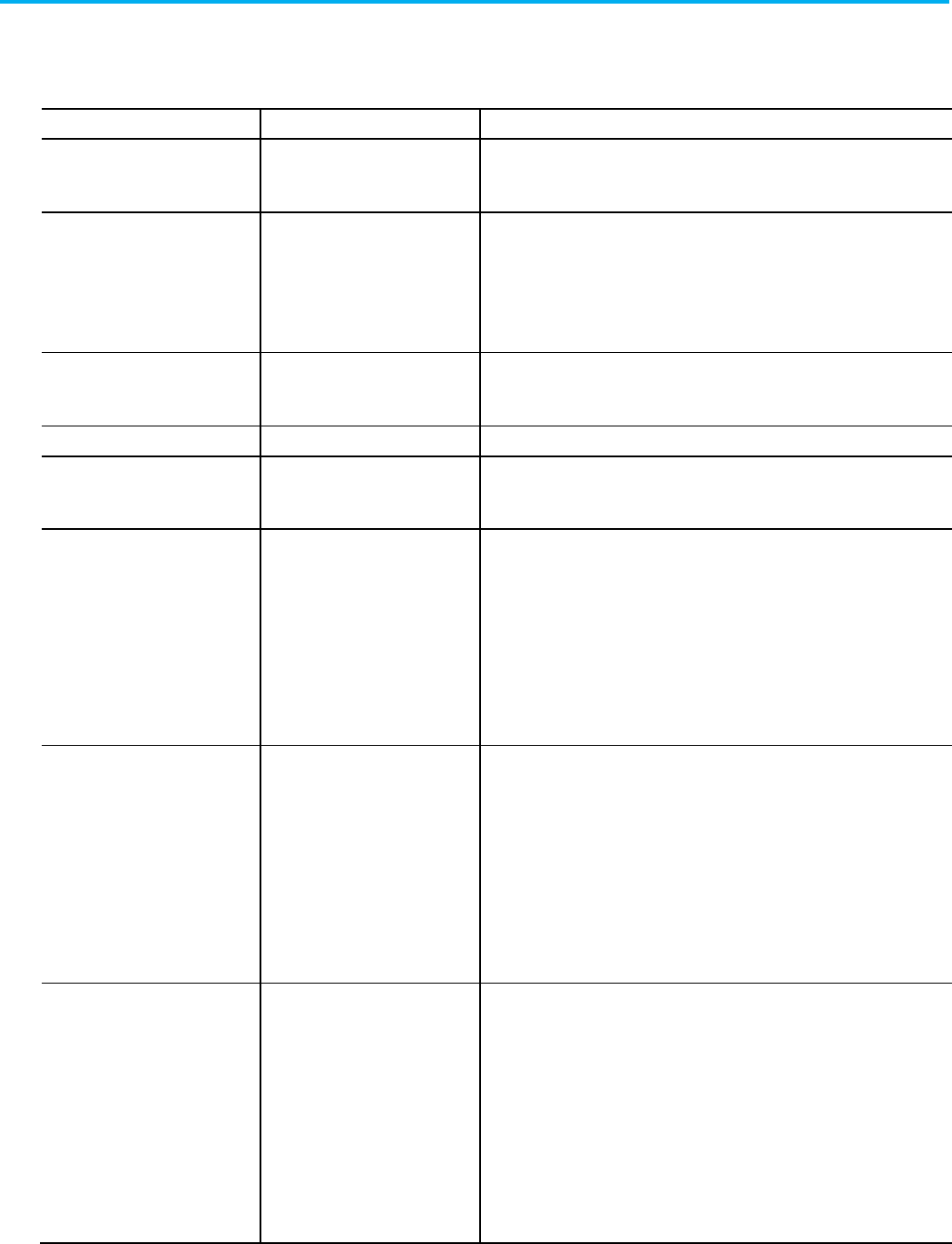

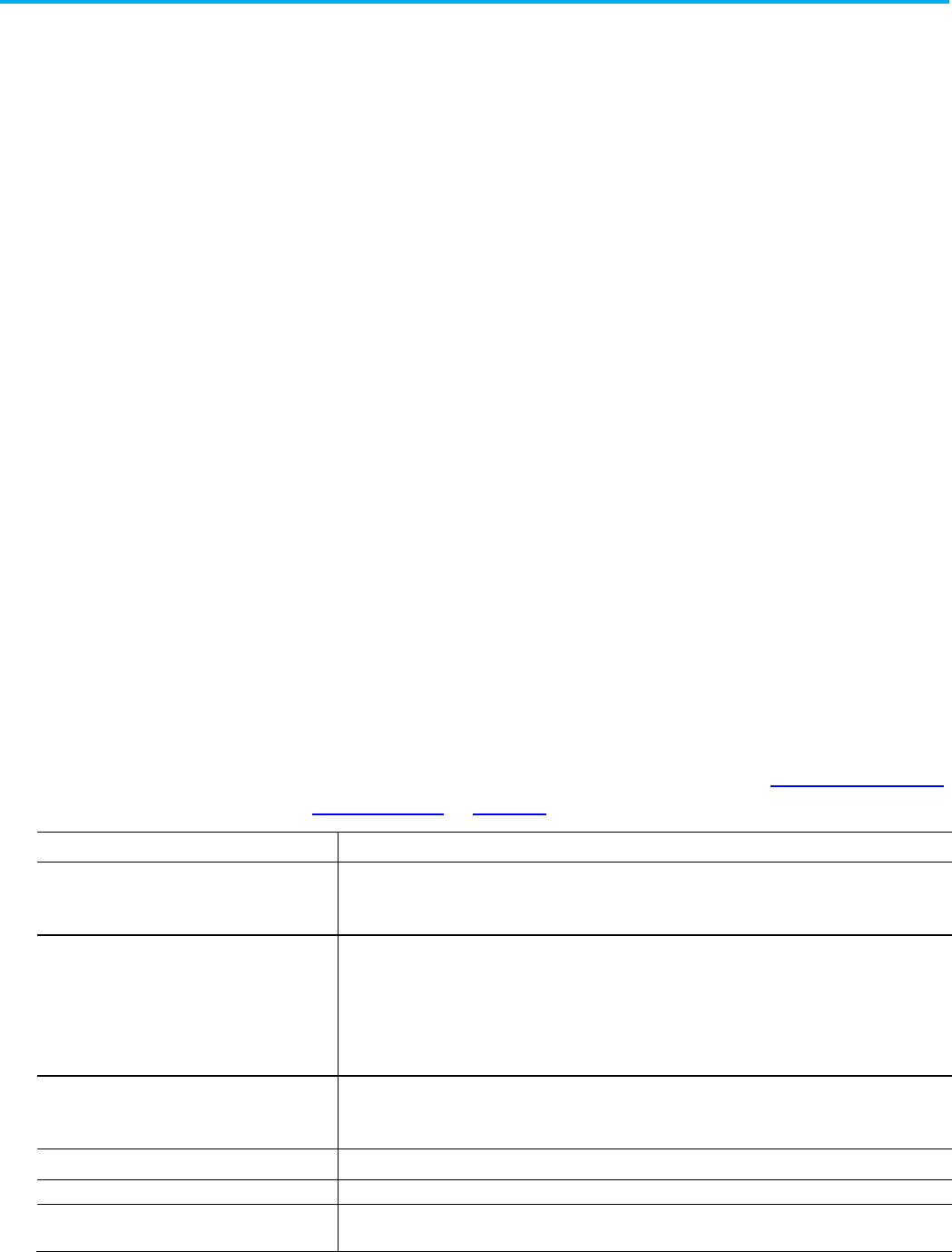

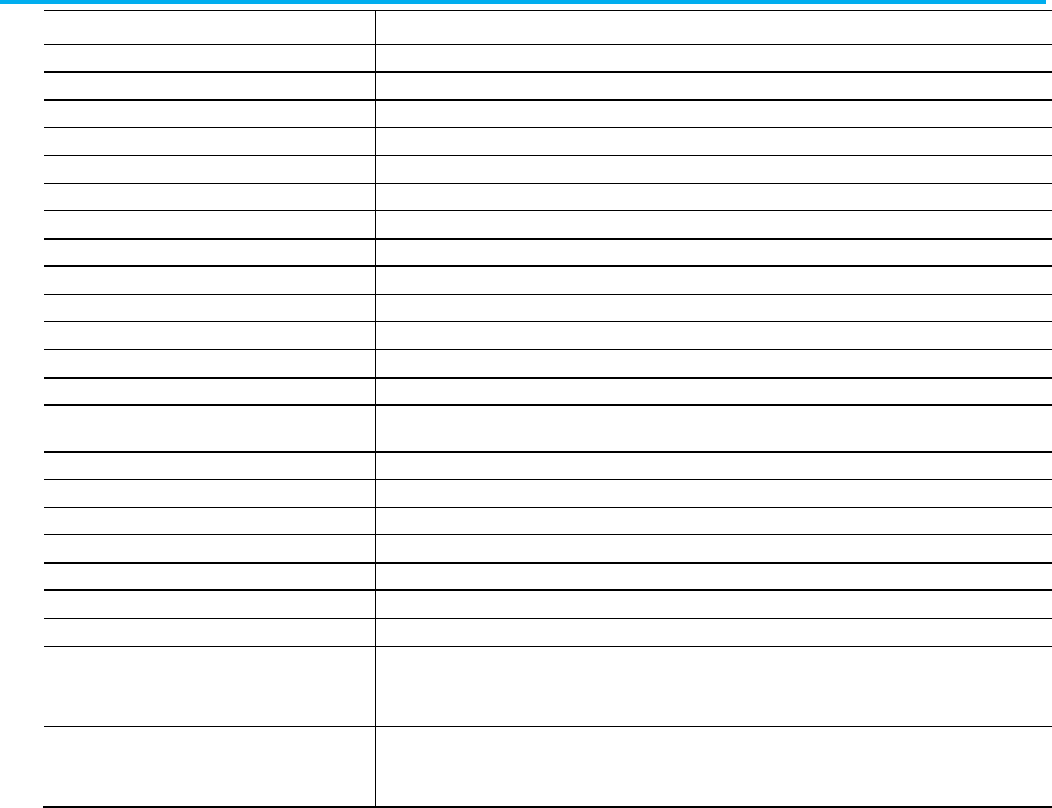

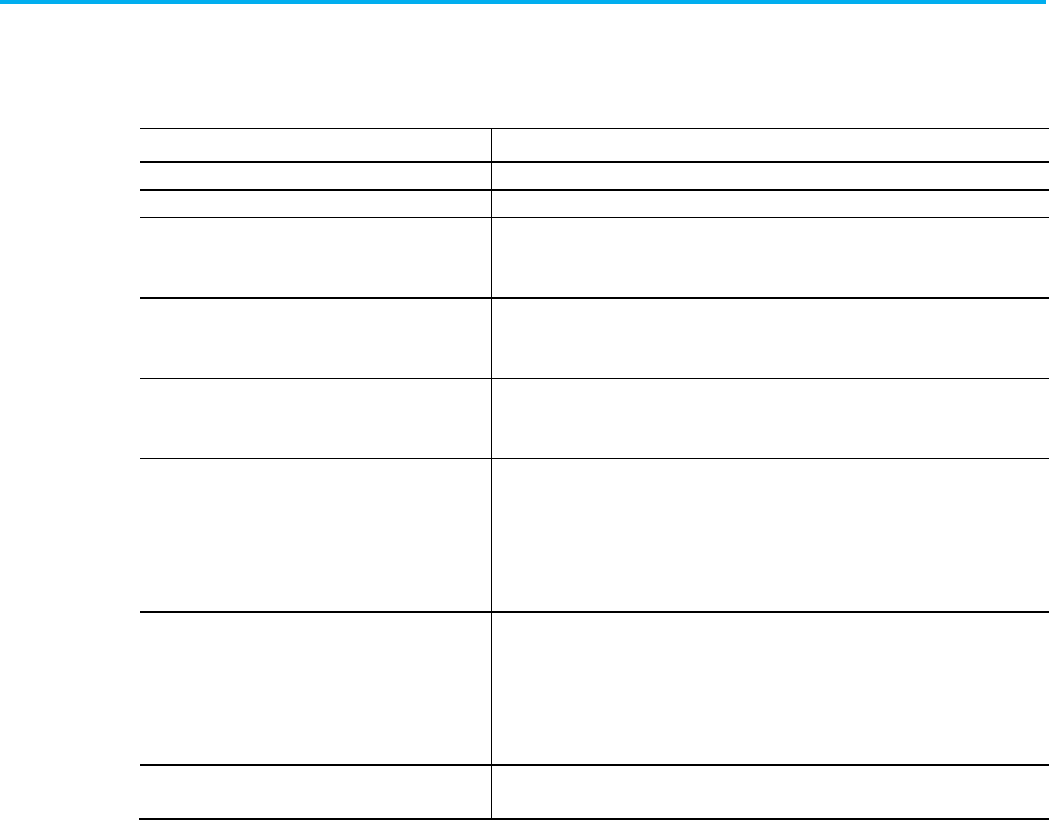

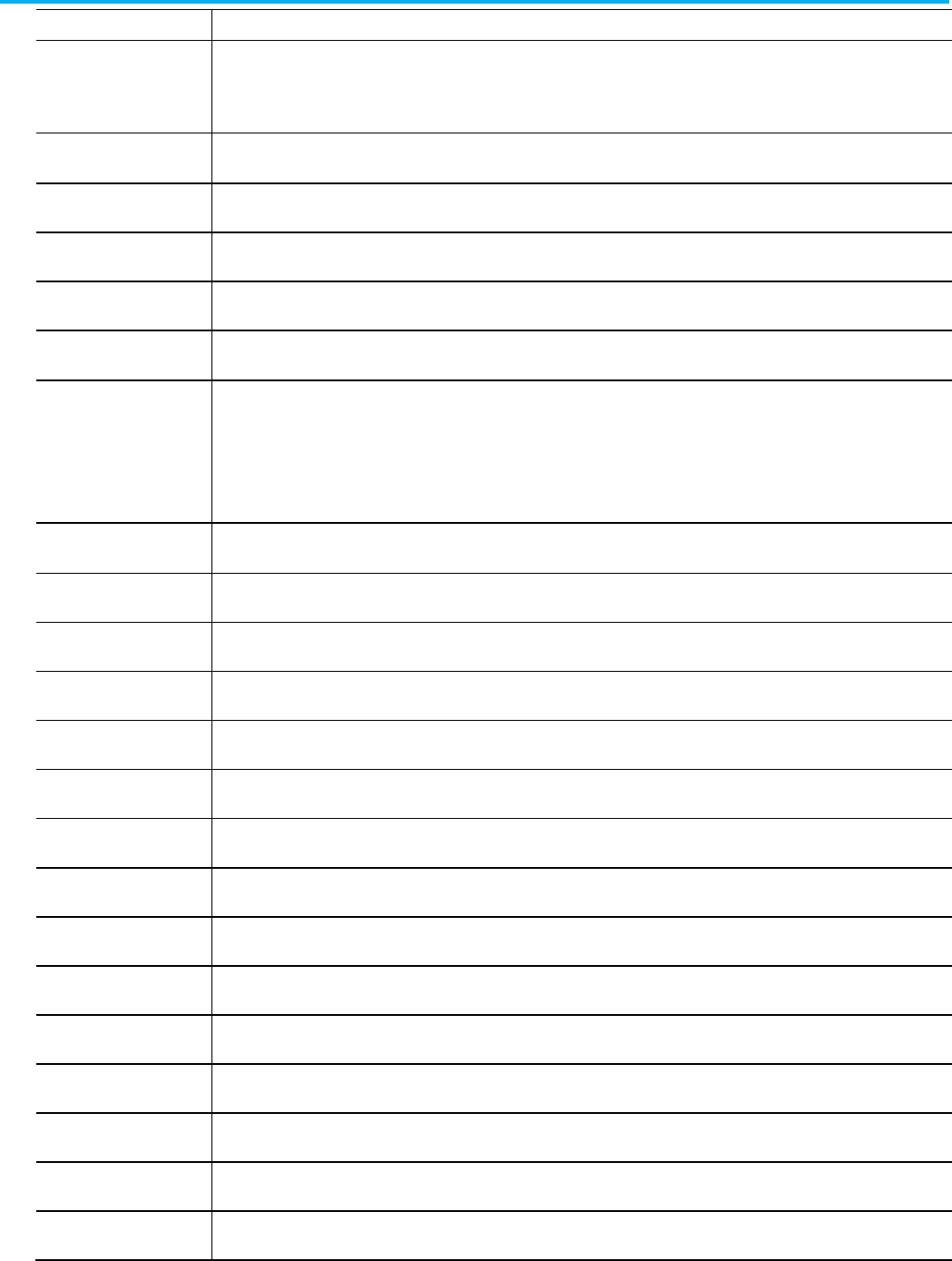

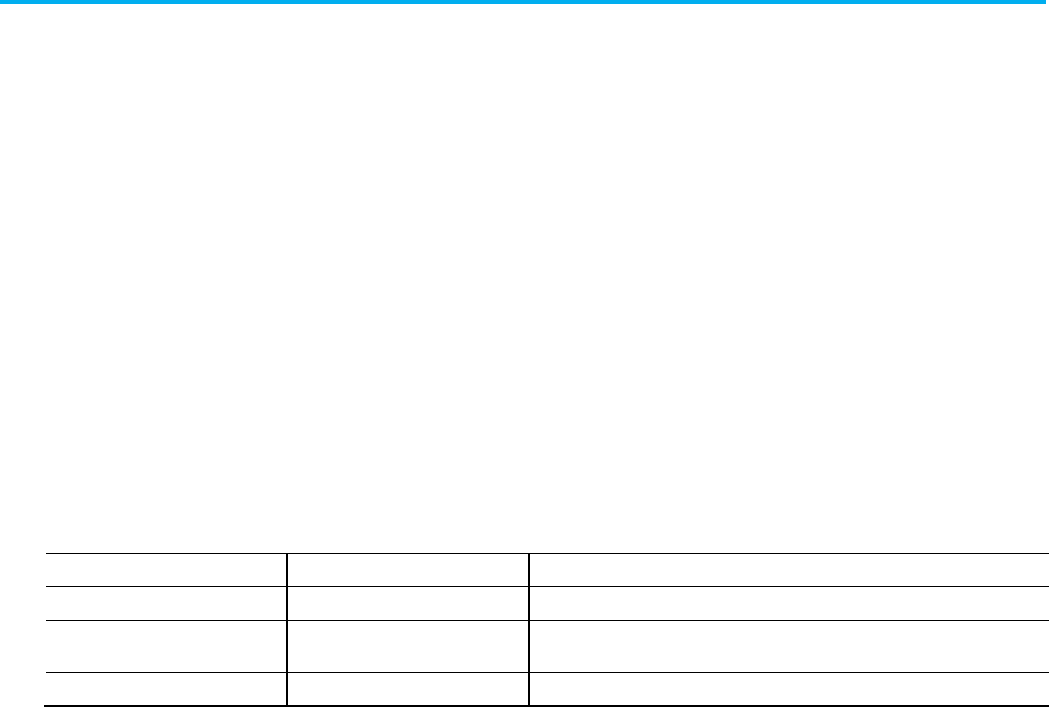

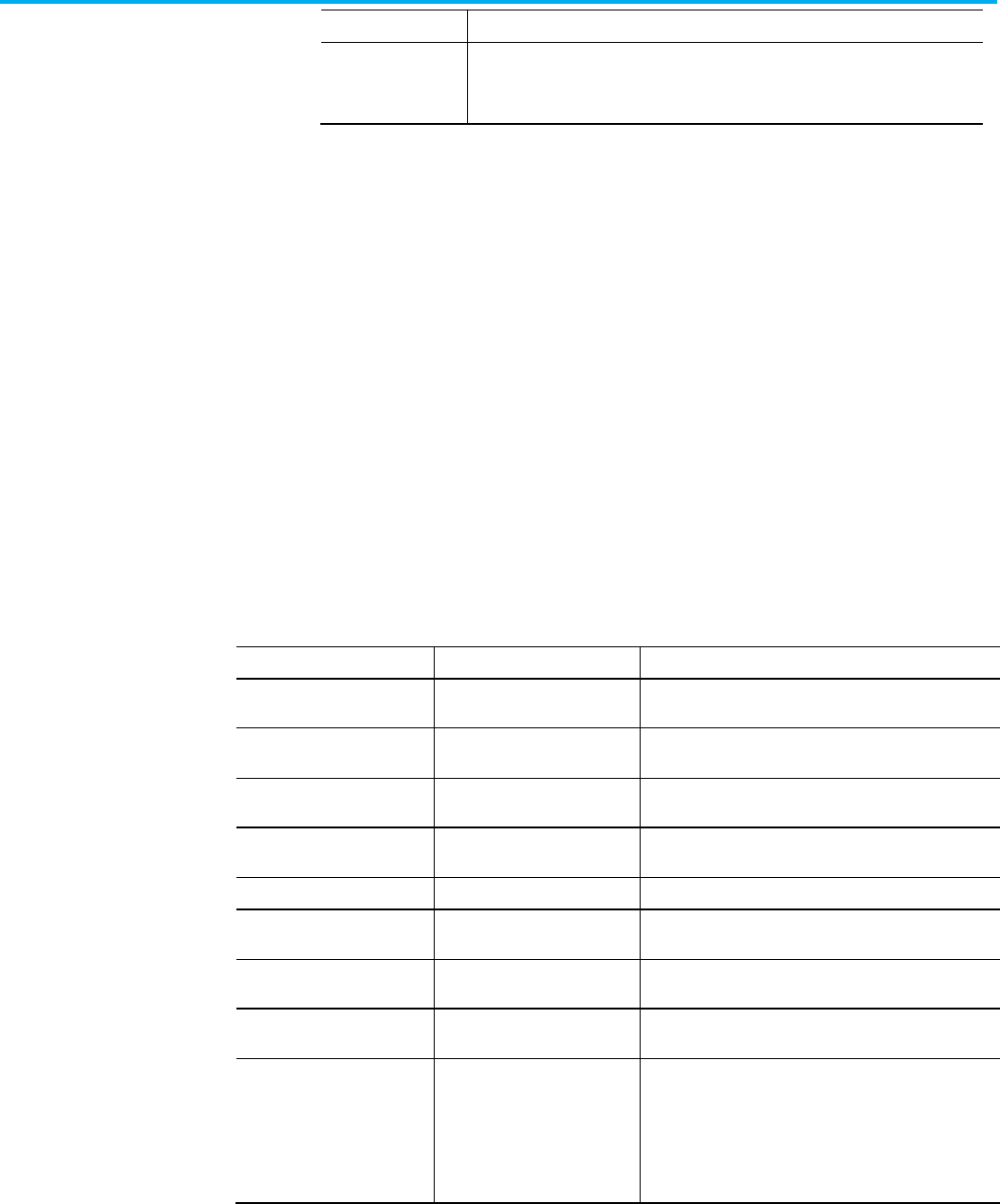

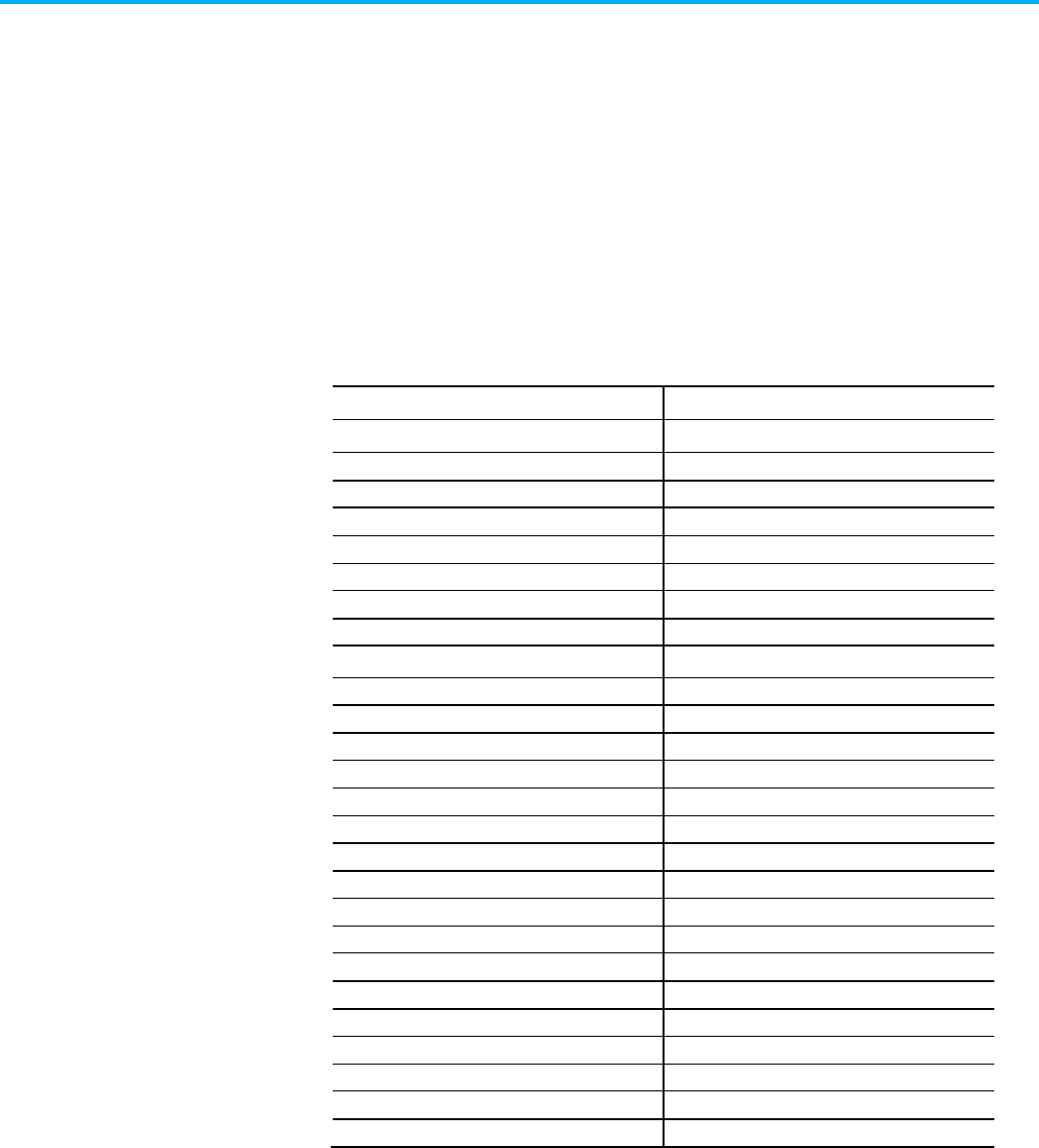

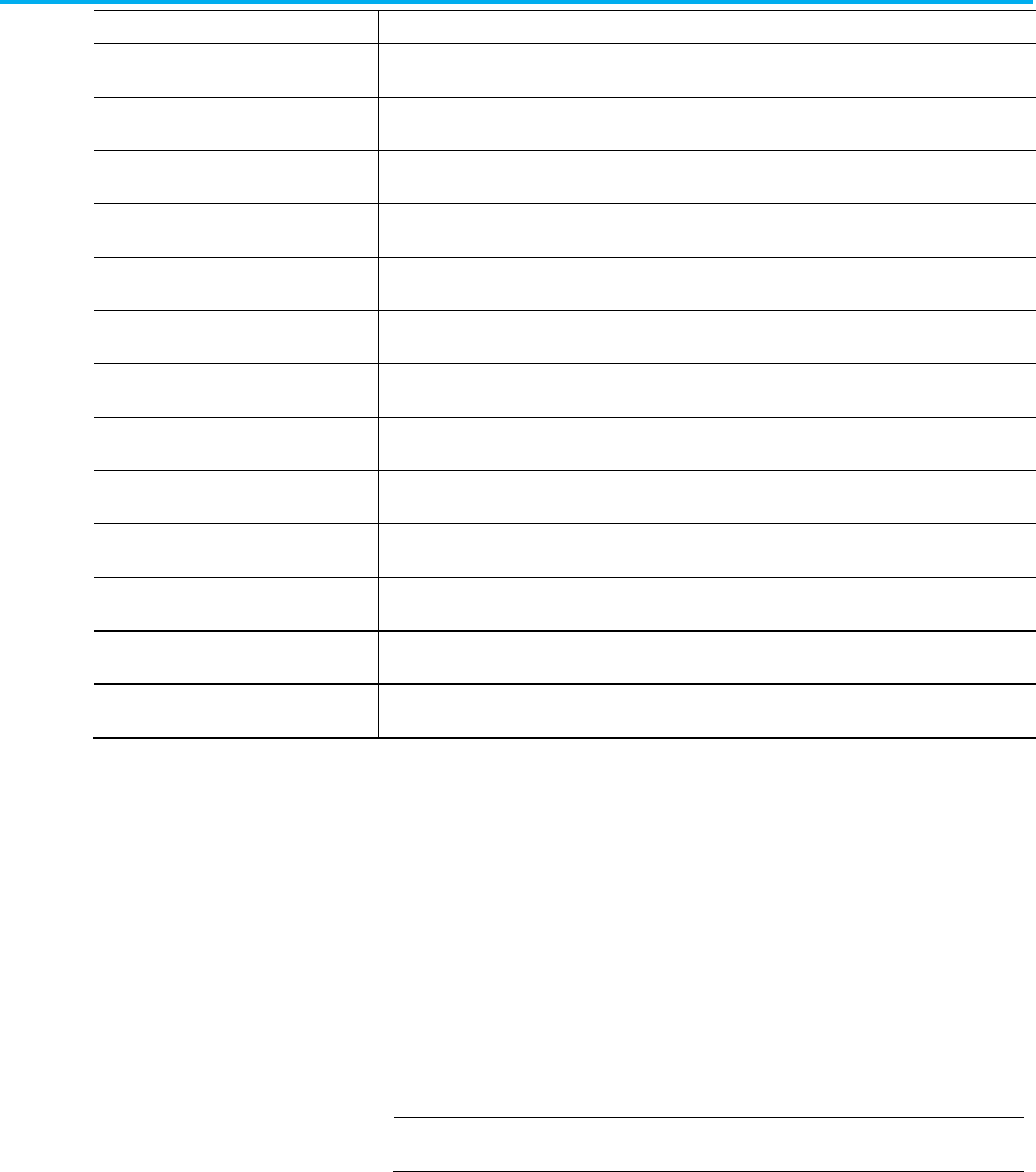

Change

Topic

Updated topic Tag attributes on page 108

Updated topic Import and export revision history introduction

on page 293

New or enhanced features

This table lists new features in this release:

• OPC UA access.

• Safety signature elements.

Change

Topic

Added a new chapter

Define safety signatures on page 271

Added new topic Export a project to an .L5X text file for projects

with OPC UA Access on page 28

Added new topic Export a project to an .L5K text file for projects

with OPC UA Access on page 27

Publication 1756-RM014B-EN-P - November 2023 5

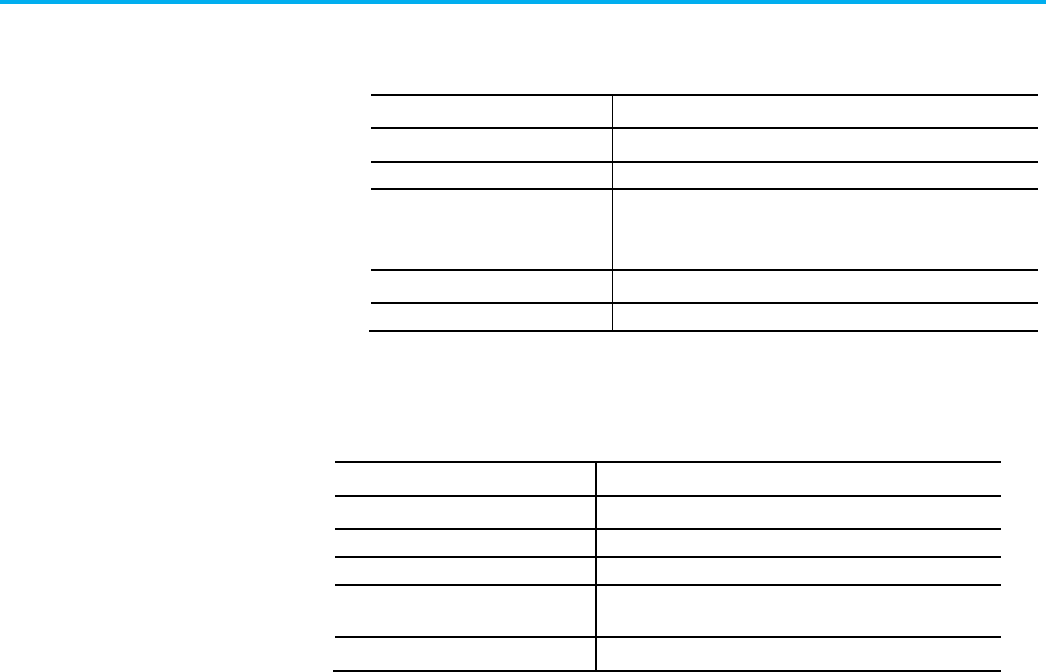

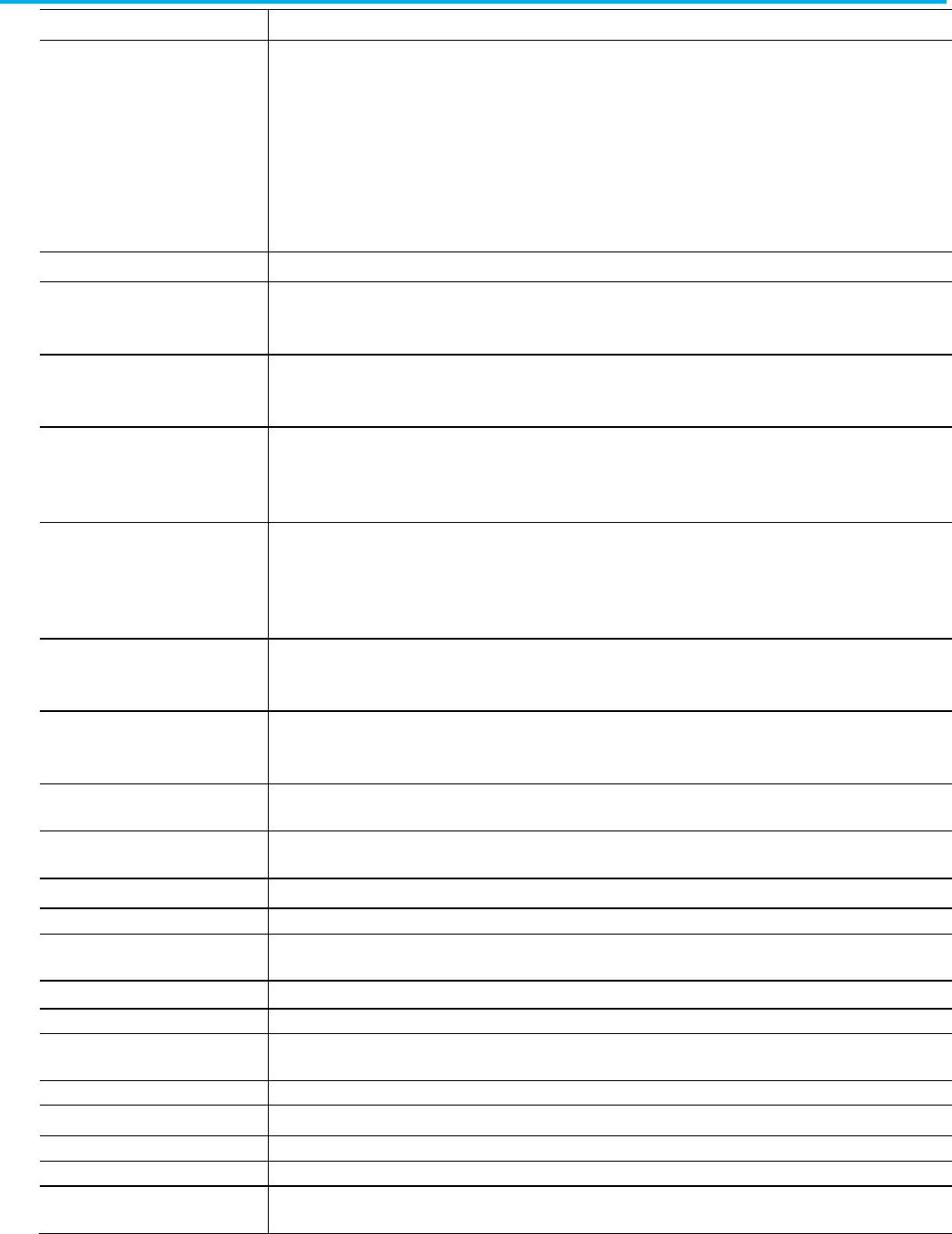

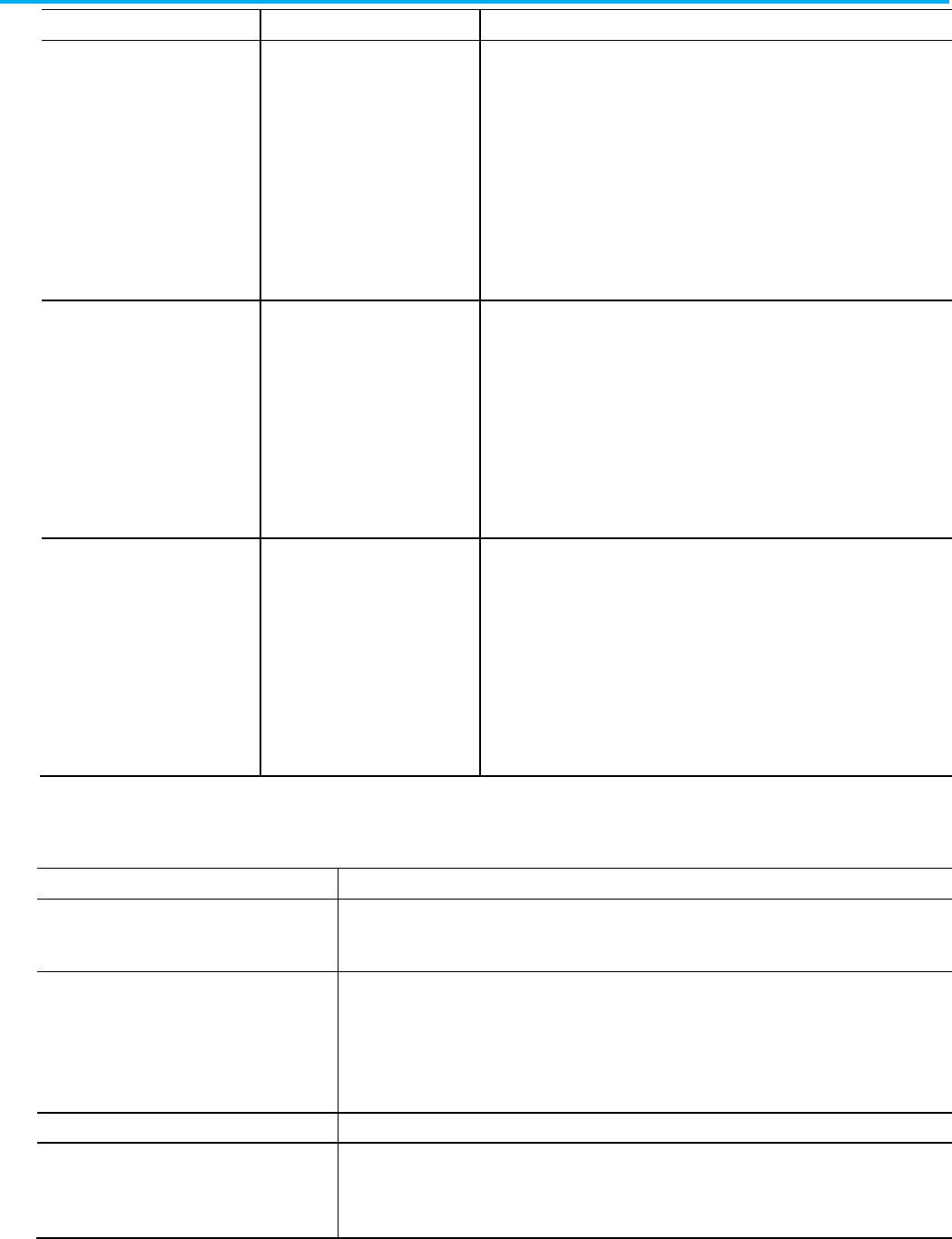

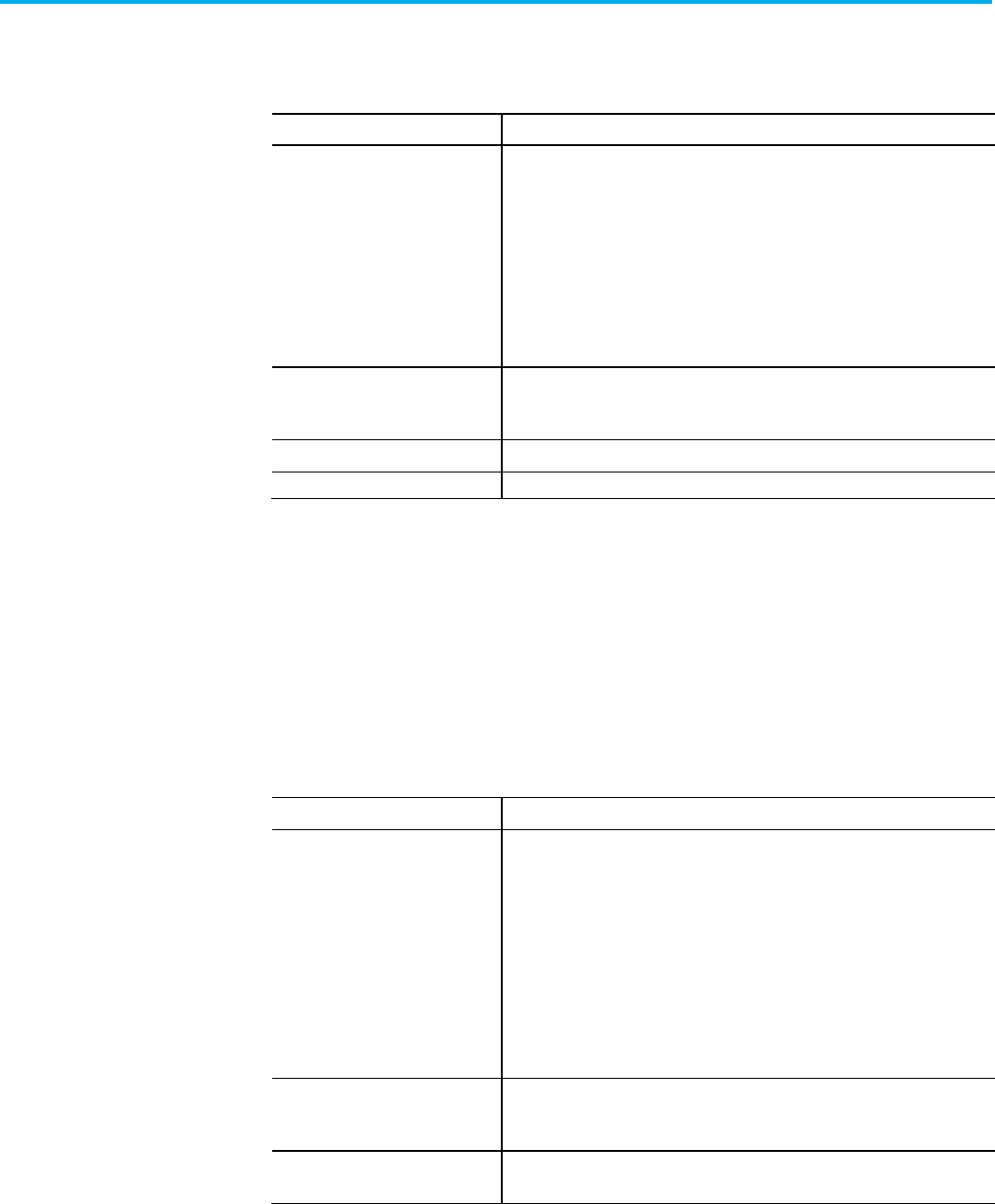

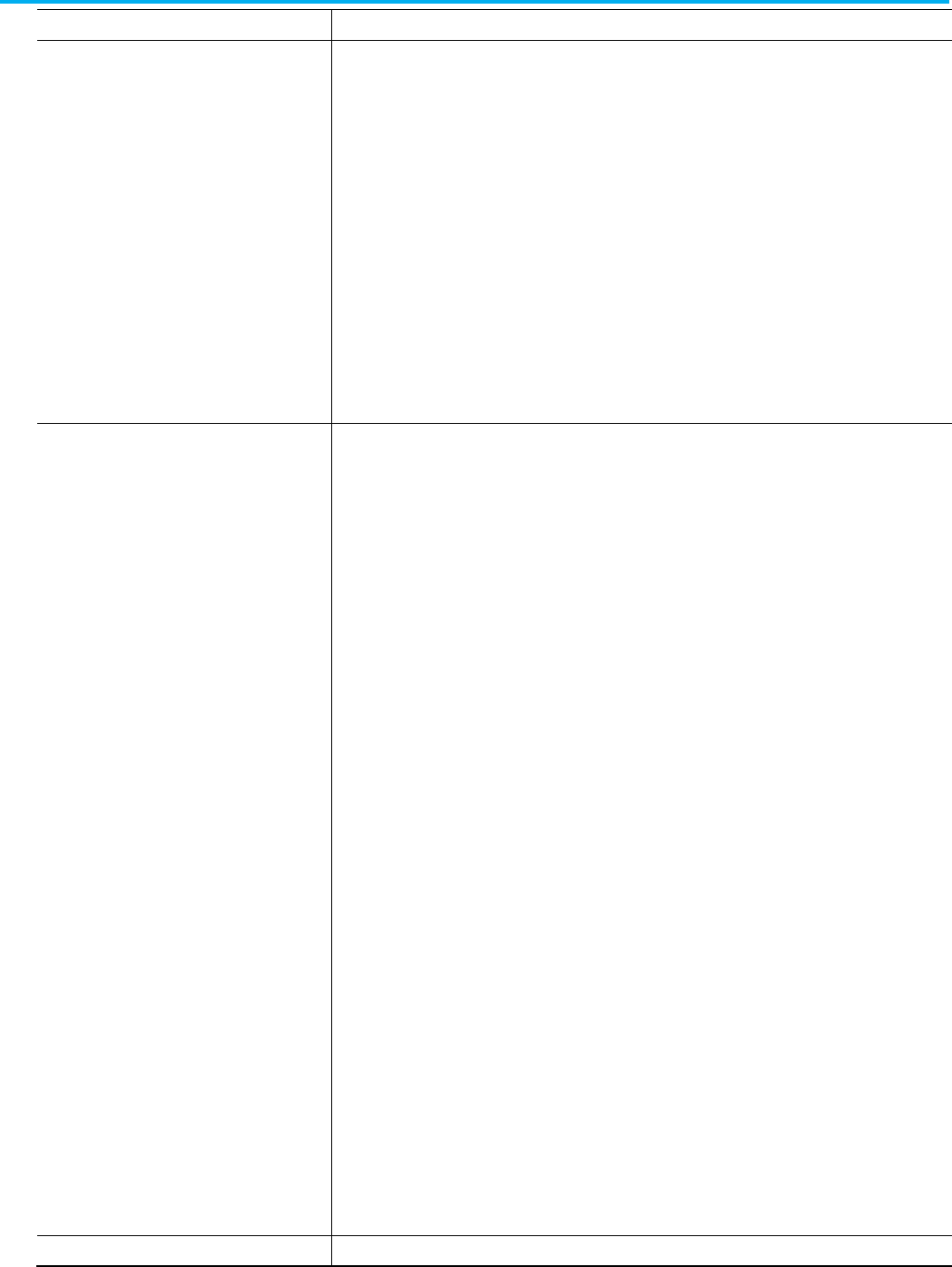

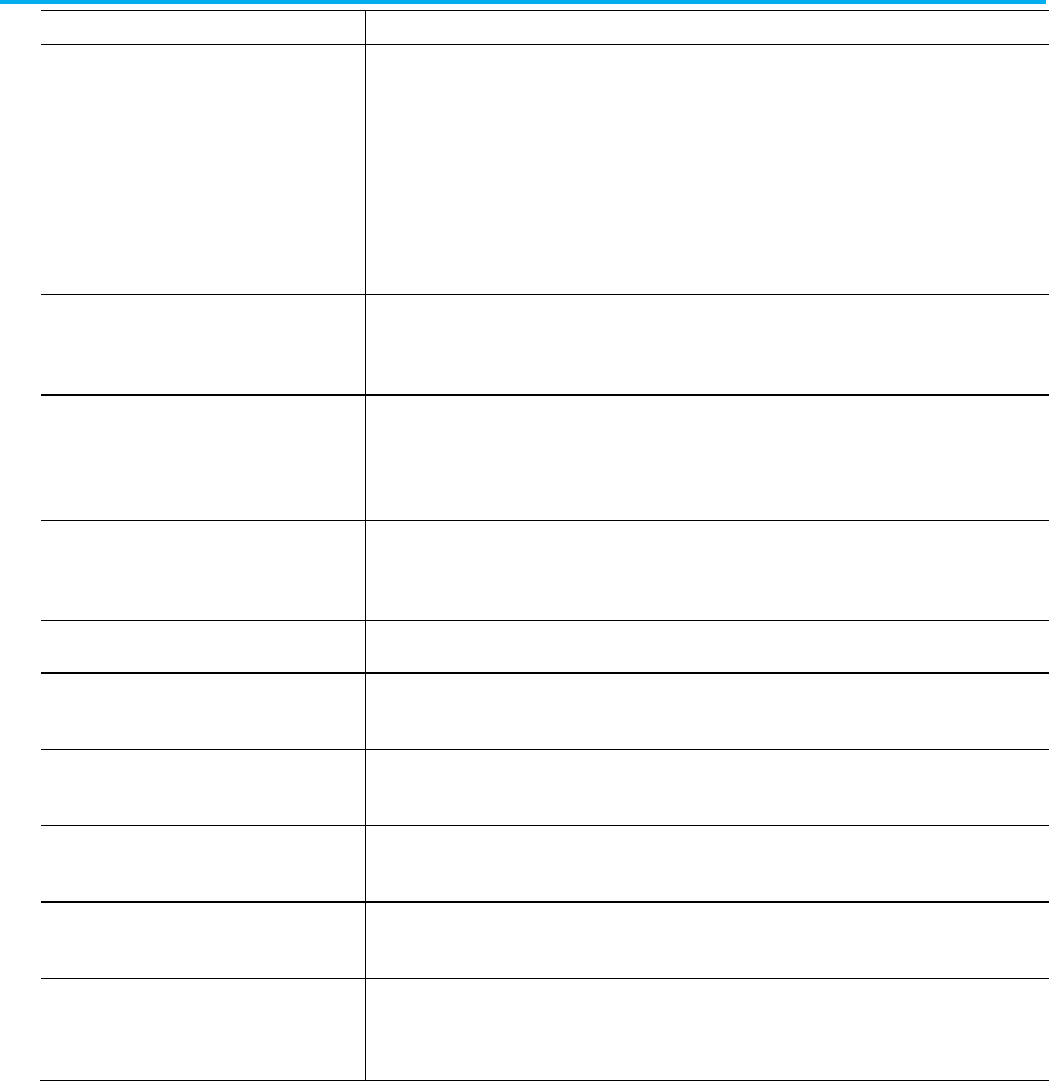

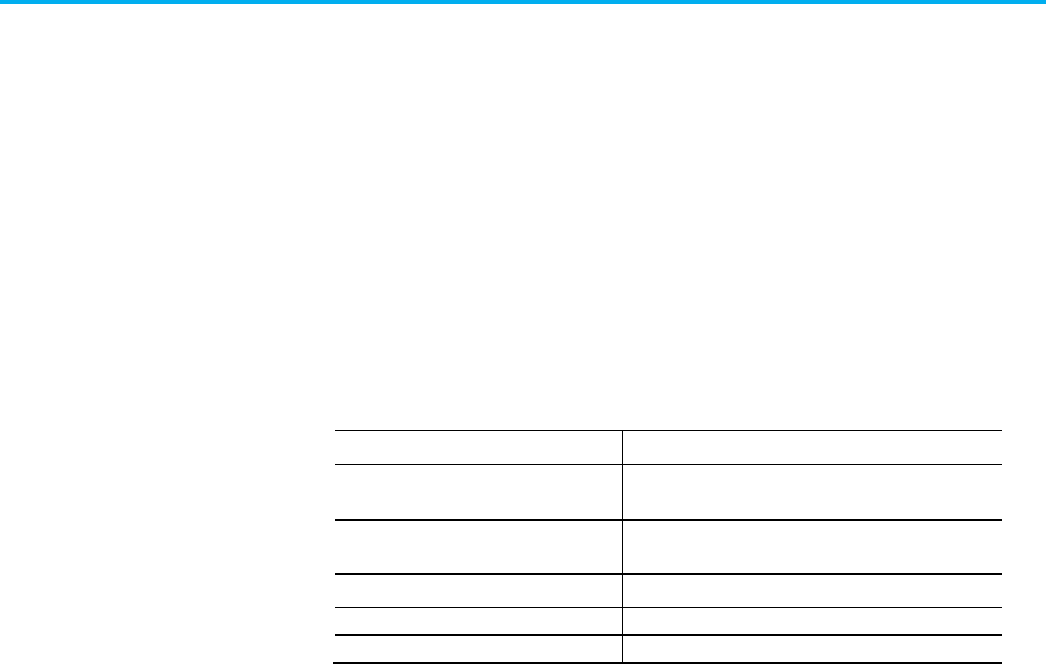

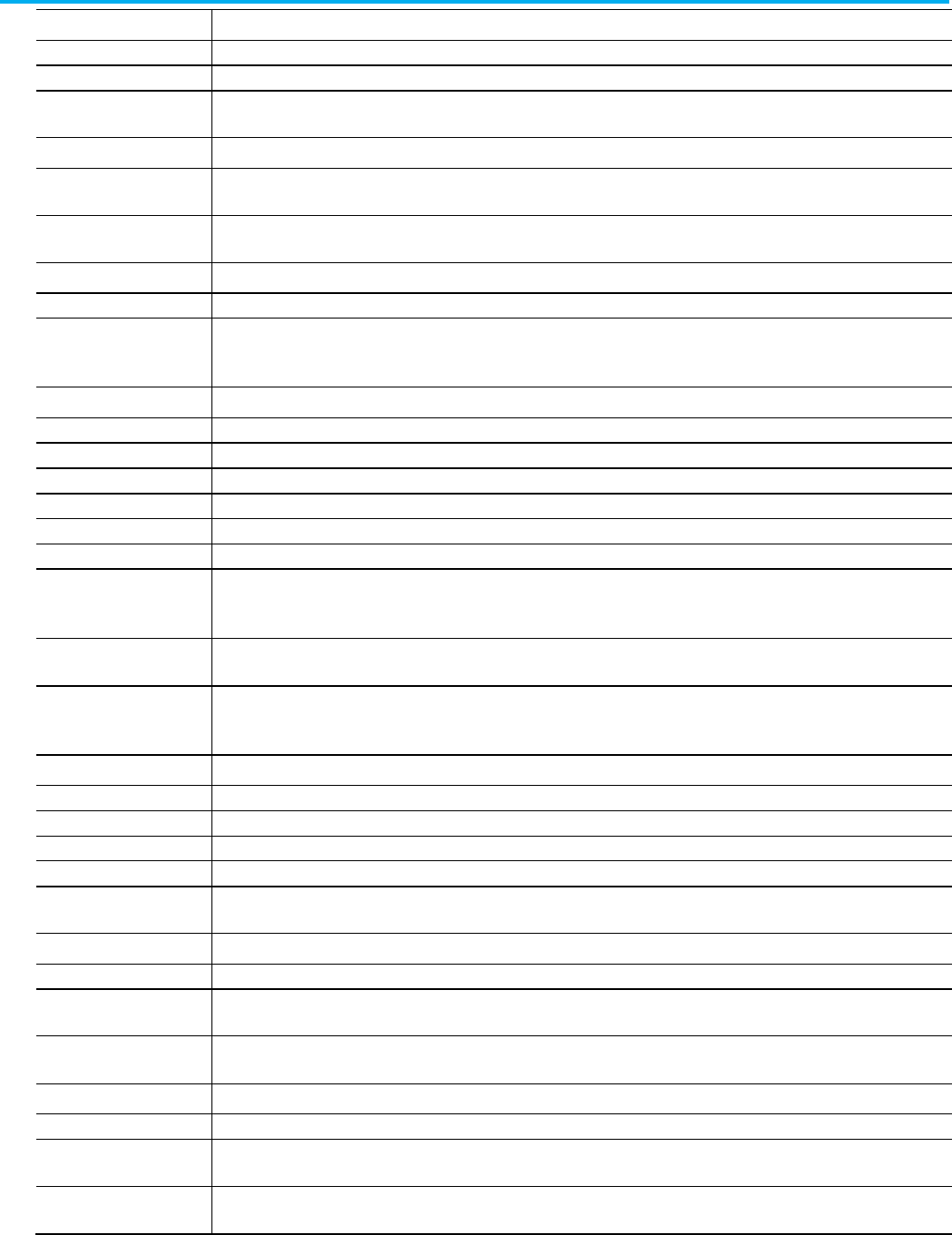

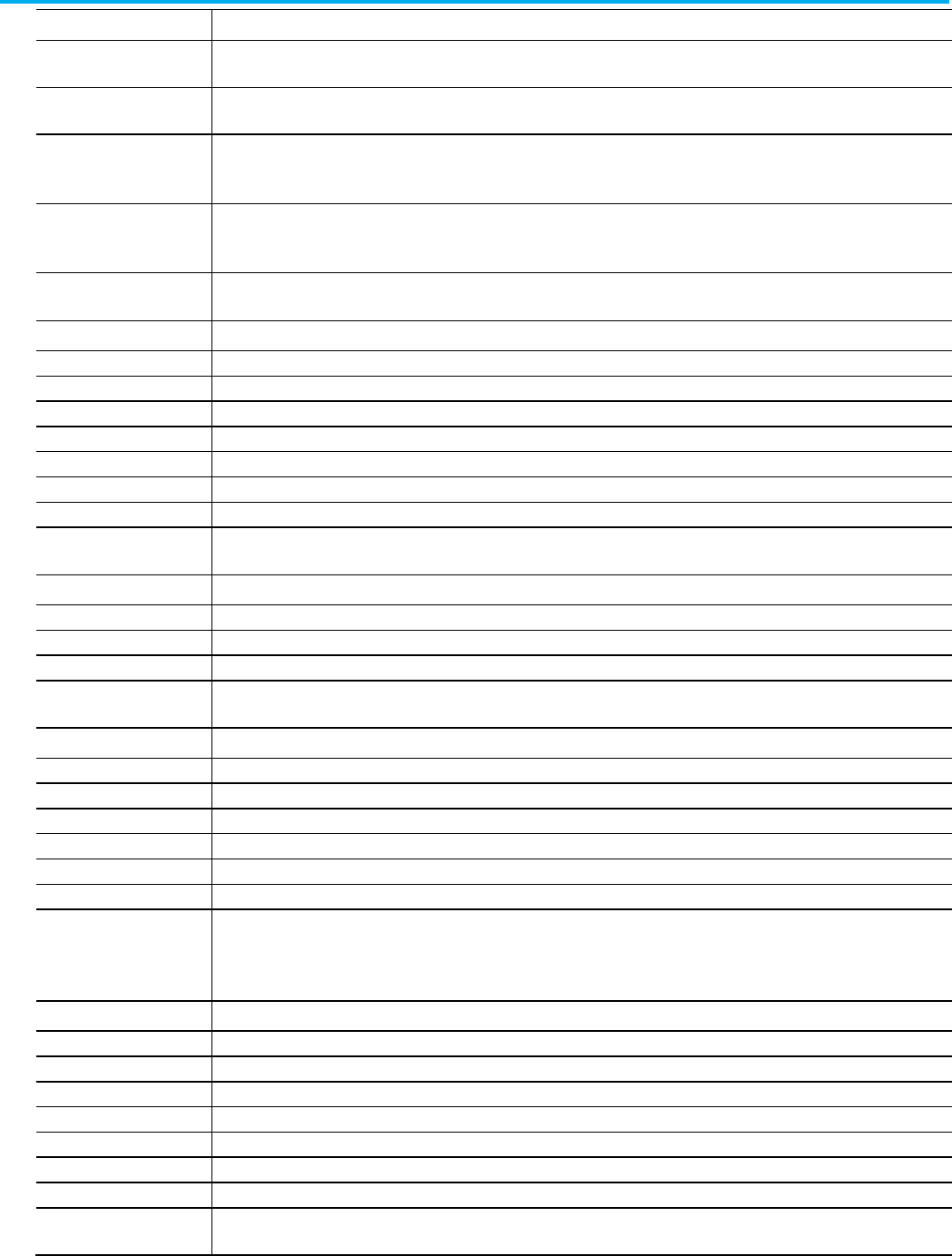

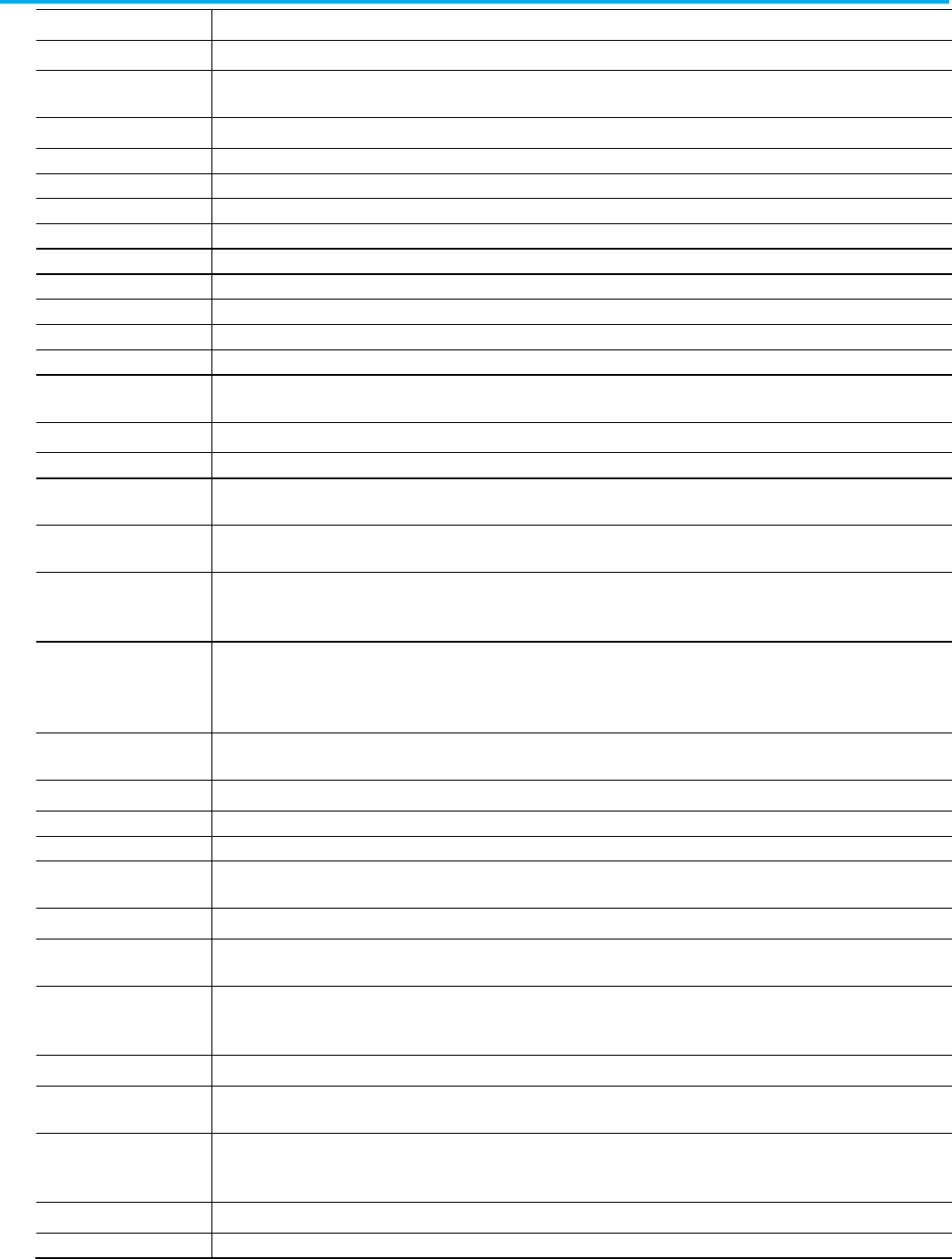

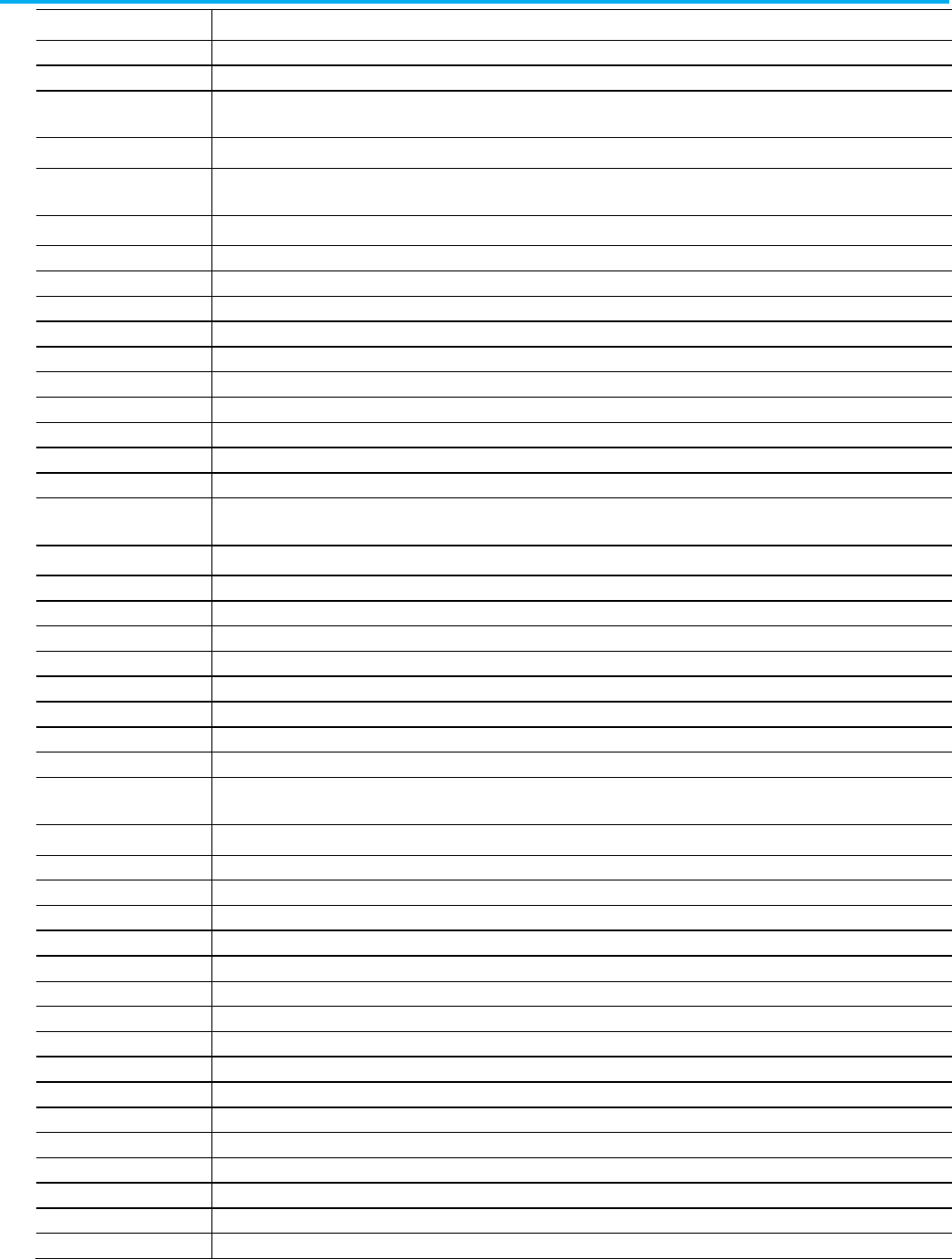

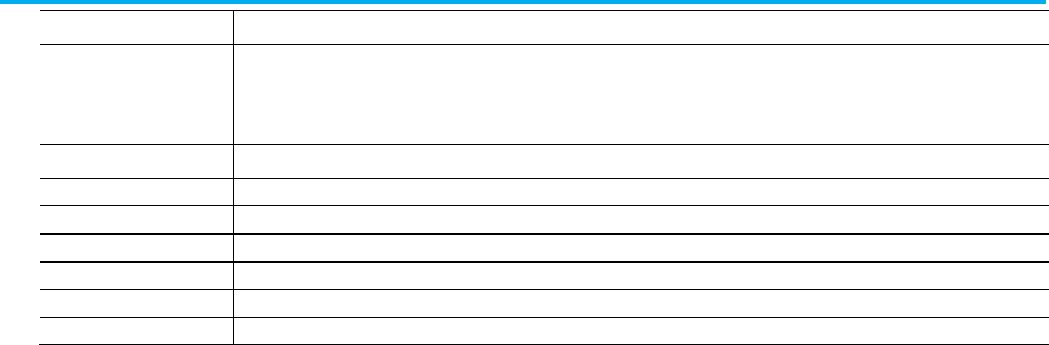

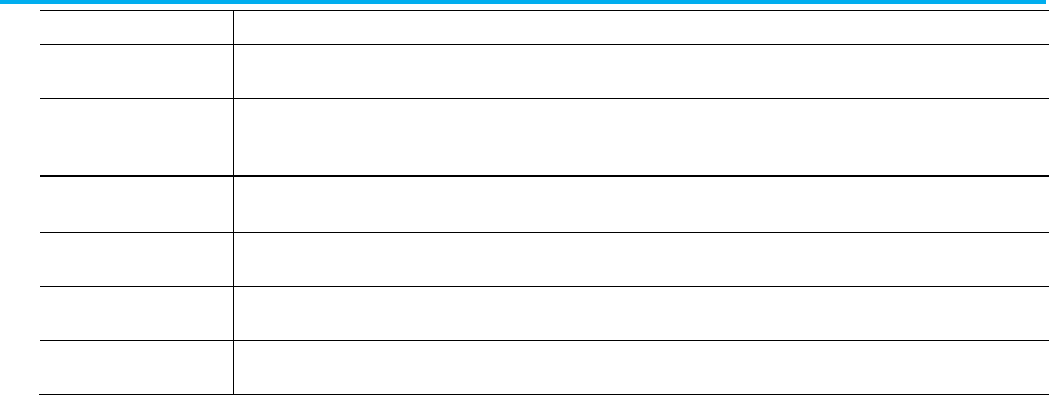

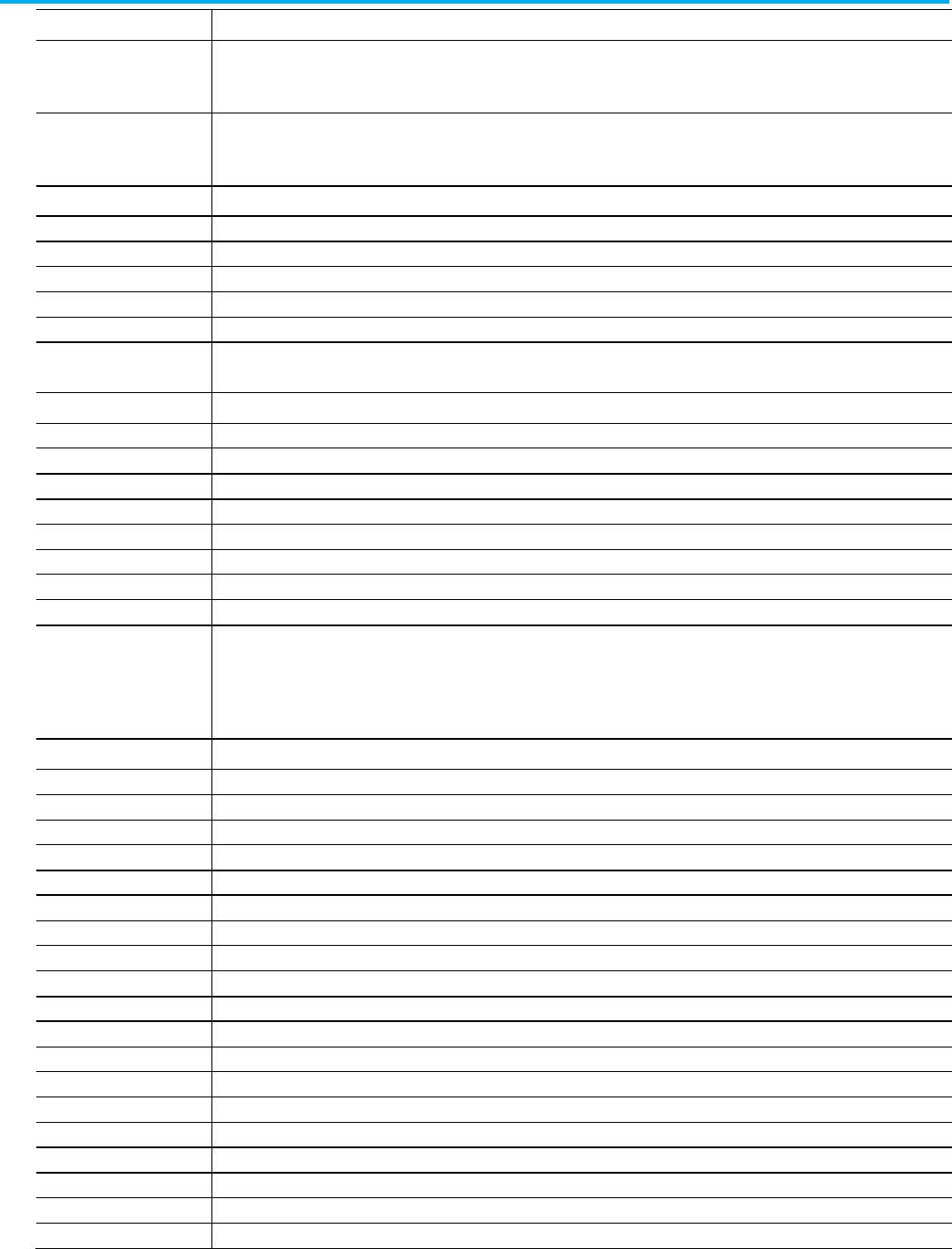

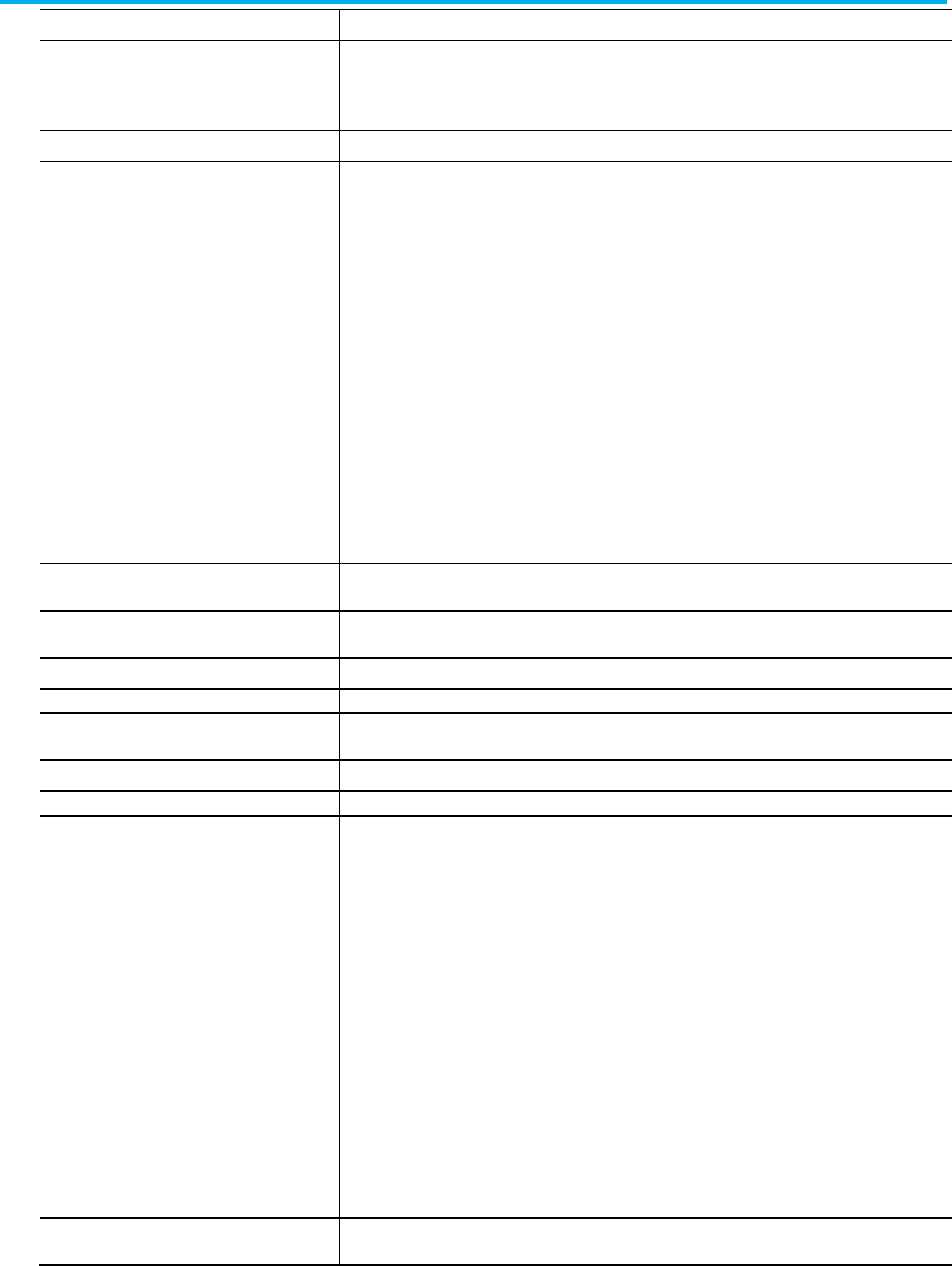

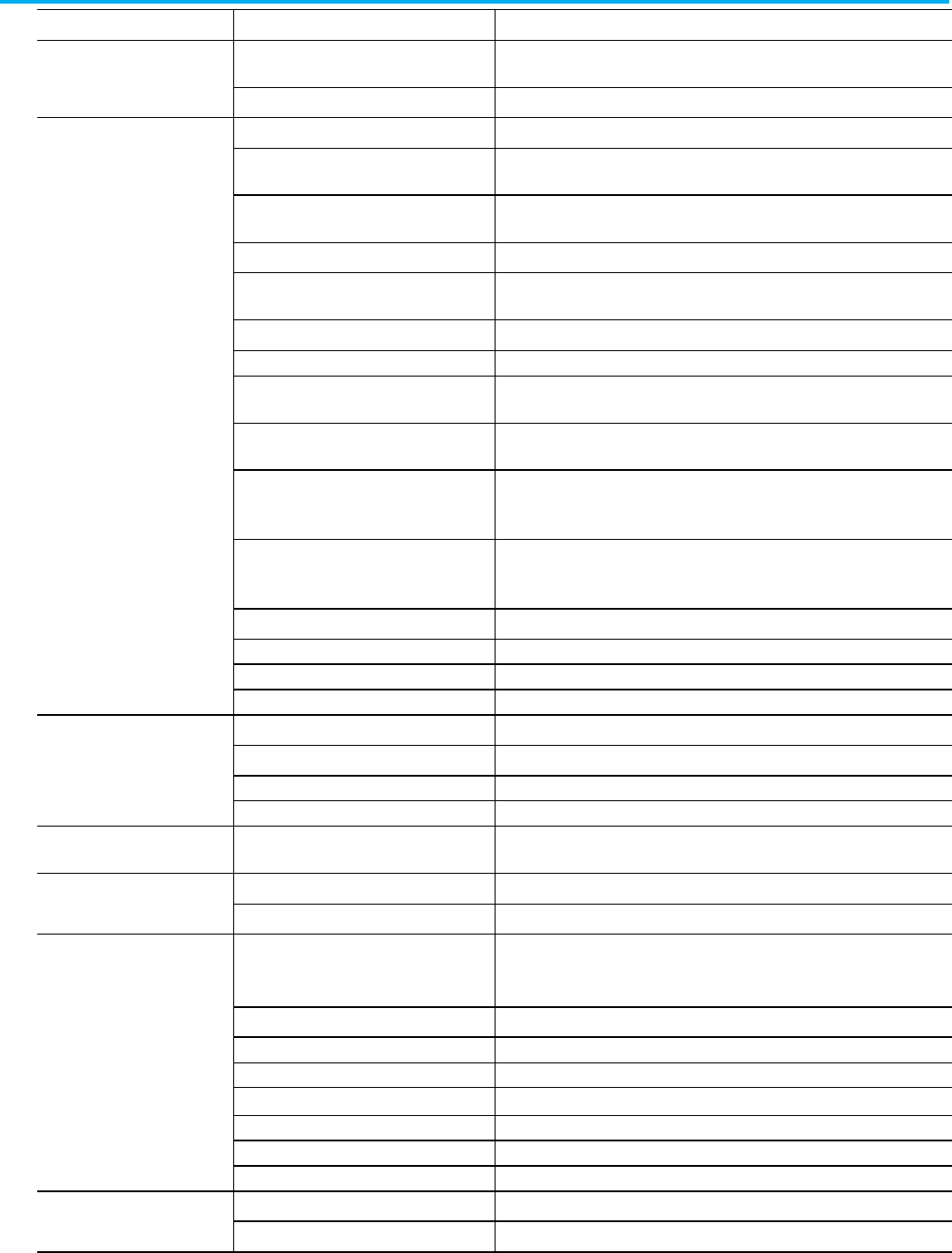

Table of Contents

Studio 5000 environment ......................................................................... 19

Supported controllers ................................................................................20

Additional resources .................................................................................. 22

Legal Notices .............................................................................................. 22

Chapter 1

Import and export introduction ............................................................... 23

Export a project to an .L5K text file .......................................................... 23

Import an .L5K text file ............................................................................. 24

Export a project to an .L5K text file for projects with OPC UA Access ...27

Export a Project to an .L5X XML File ........................................................27

Export a project to an .L5X text file for projects with OPC UA Access .. 28

Import an .L5X XML File........................................................................... 28

Export to a .CSV or .TXT file ...................................................................... 31

Import a .CSV or .TXT file ......................................................................... 33

Export source-protected logic ................................................................... 35

Export in a Cleartext Format............................................................... 36

Maintaining controller access ................................................................... 39

.L5X file structure ...................................................................................... 40

.L5X file conventions ................................................................................. 42

L5X Internal file comments ................................................................ 42

Component Descriptions .................................................................... 43

Boolean attribute values ...................................................................... 43

Data display style.................................................................................. 43

Data formats ......................................................................................... 43

.L5K file structure ...................................................................................... 48

.L5K file conventions ..................................................................................49

L5K Internal file comments .................................................................49

Component descriptions .....................................................................49

Display style ......................................................................................... 50

Project documentation ............................................................................. 50

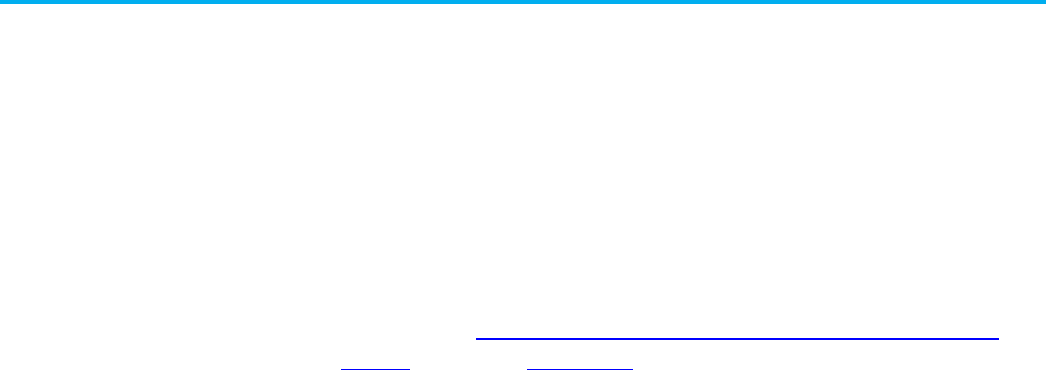

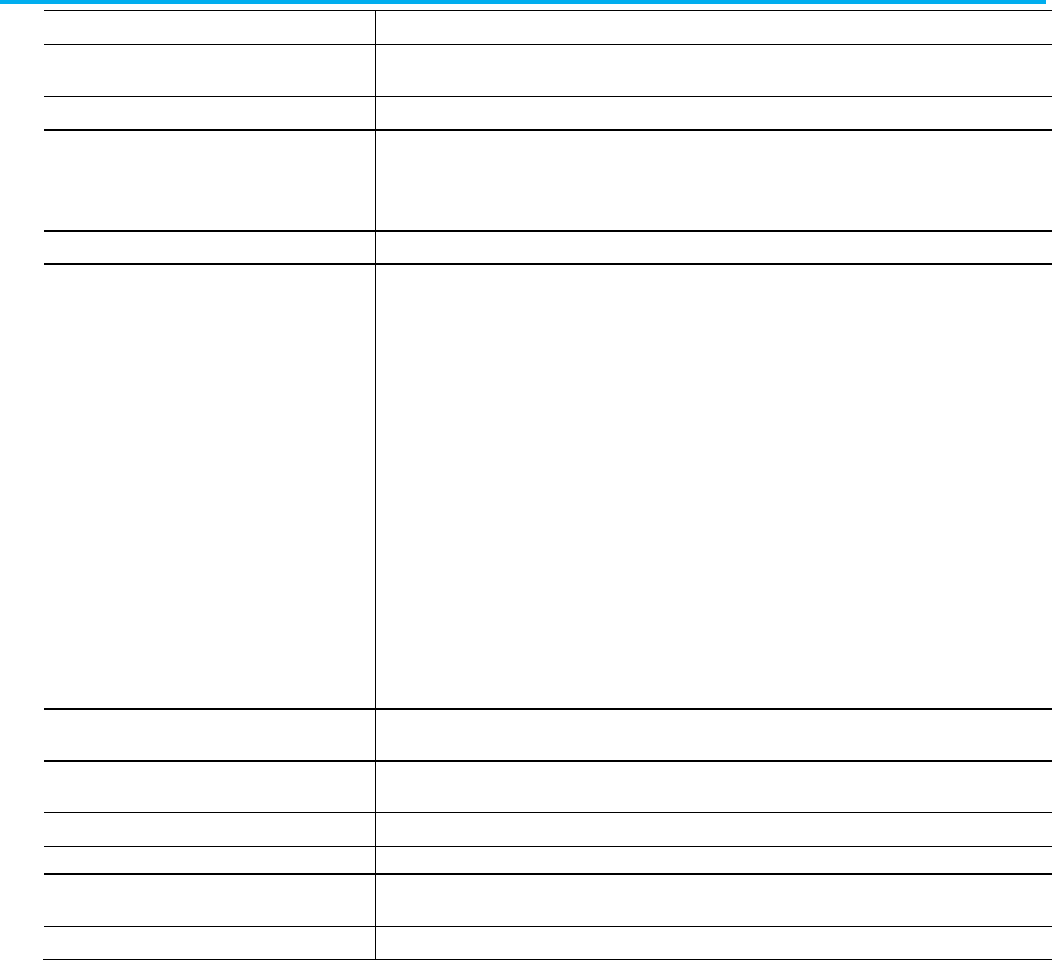

Chapter 2

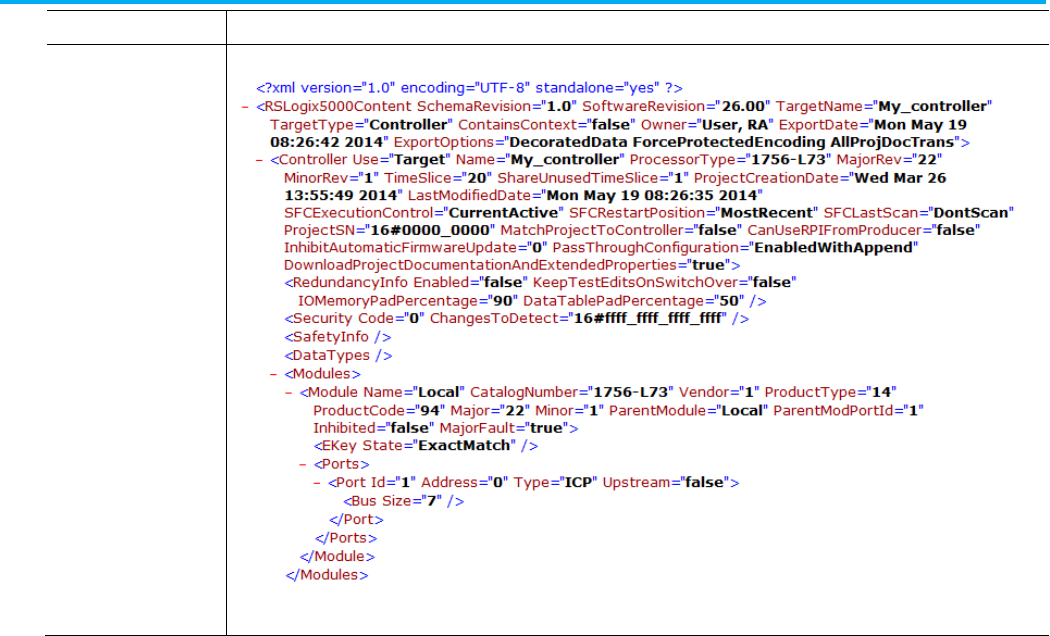

Controller component introduction......................................................... 53

Controller component ............................................................................... 53

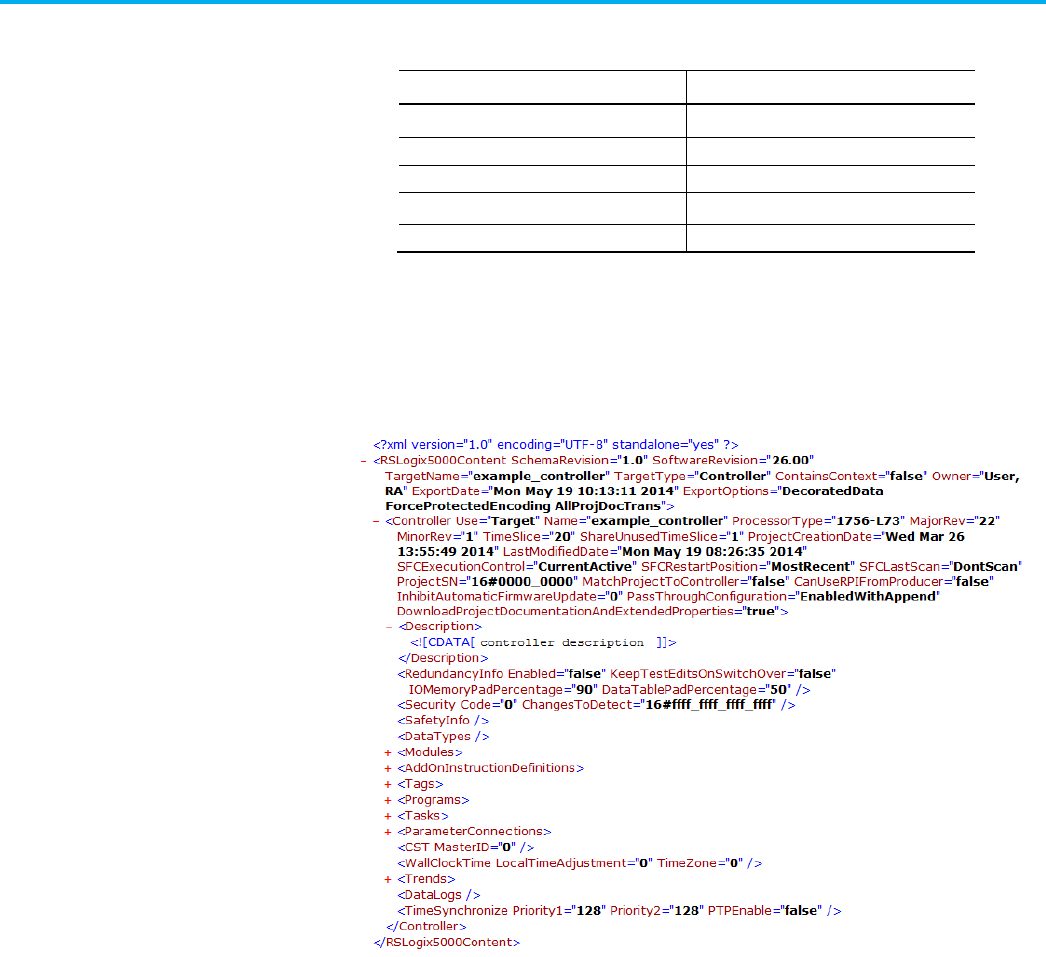

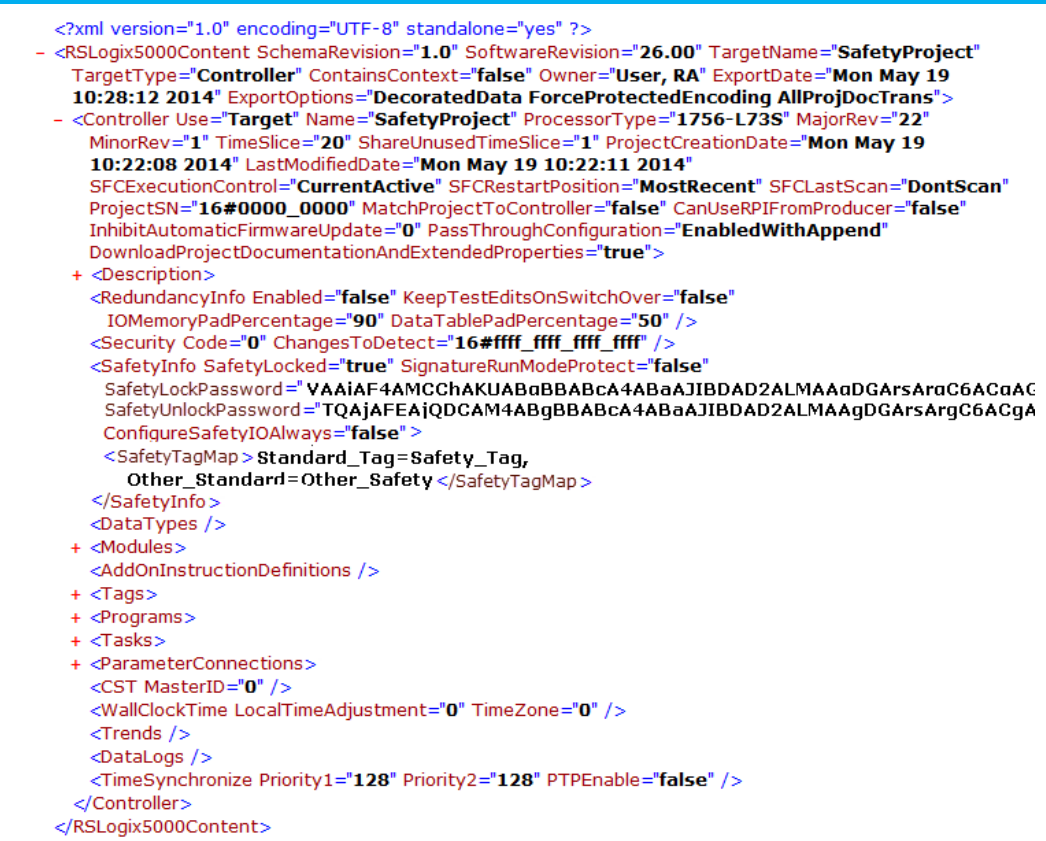

L5X controller structure....................................................................... 53

L5K CONTROLLER structure .............................................................. 55

Controller elements ............................................................................. 55

Controller attributes ............................................................................ 56

Controller attributes in a safety controller system ..................................58

Controller guidelines .................................................................................58

Summary of changes

Preface

Import and export files

Define a controller component

Table of Contents

6 Publication 1756-RM014B-EN-P - November 2023

Controller component examples ............................................................... 59

Chapter 3

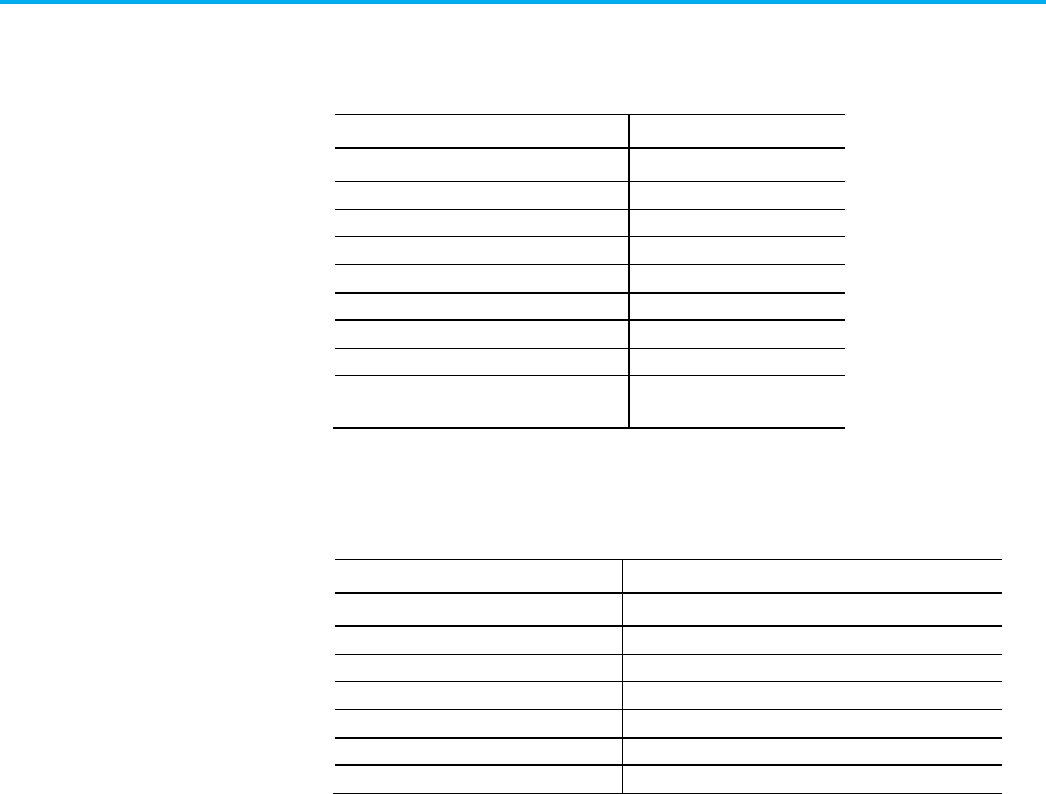

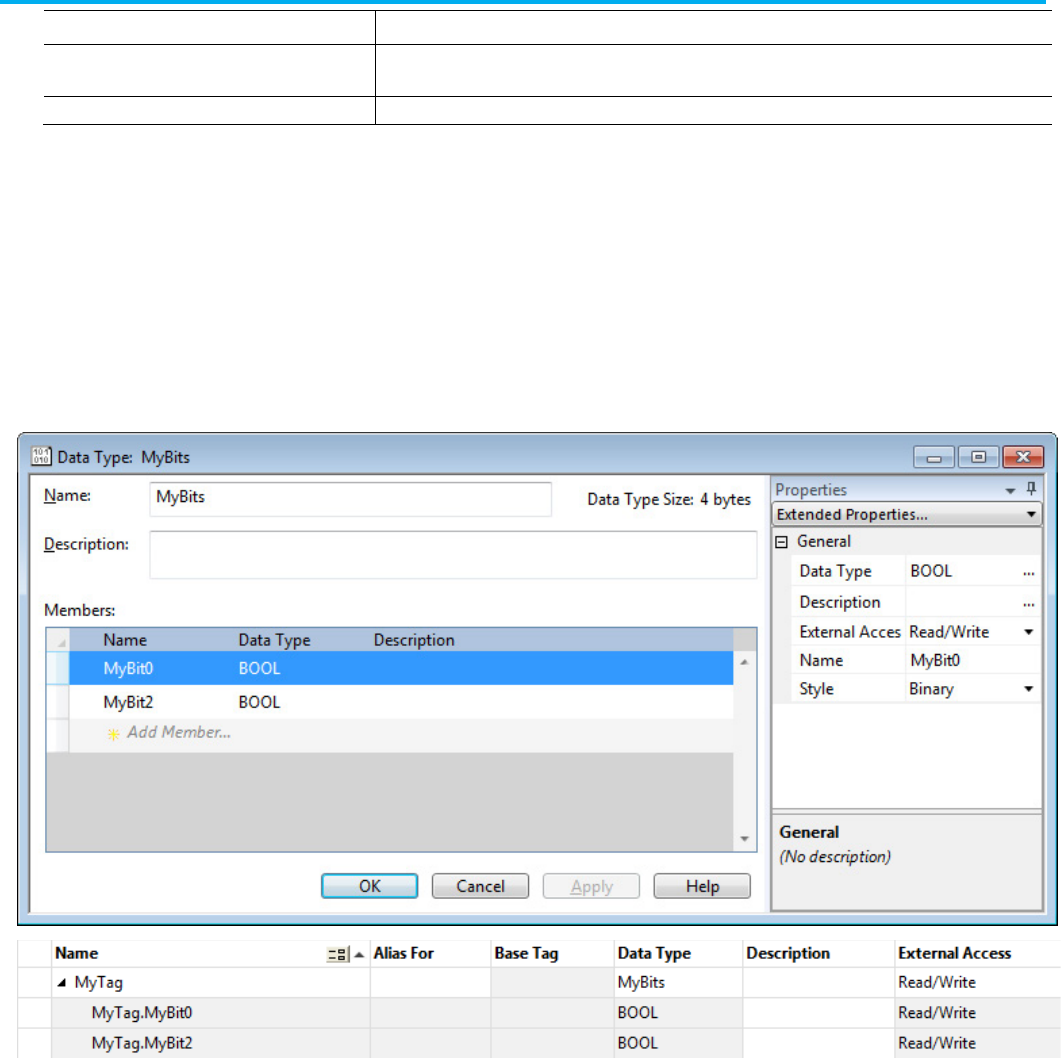

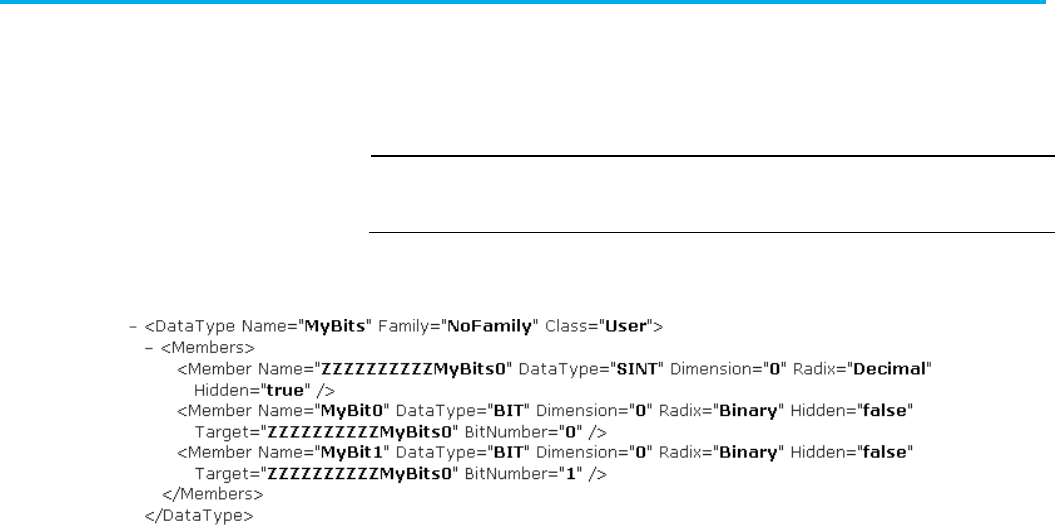

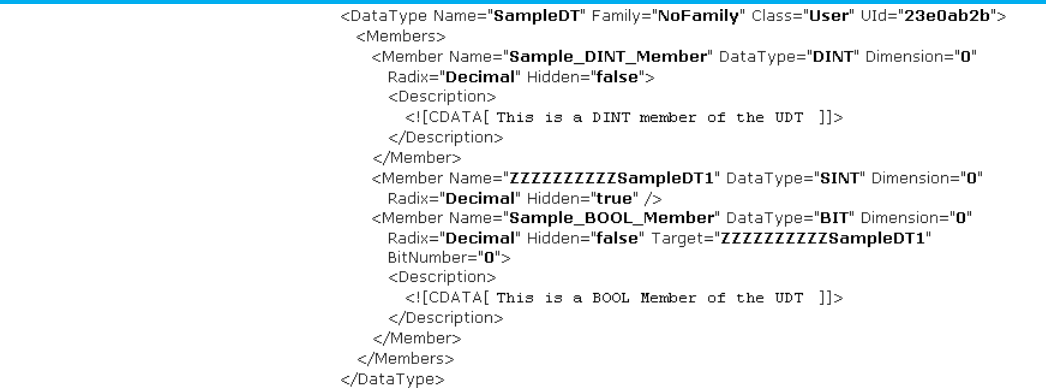

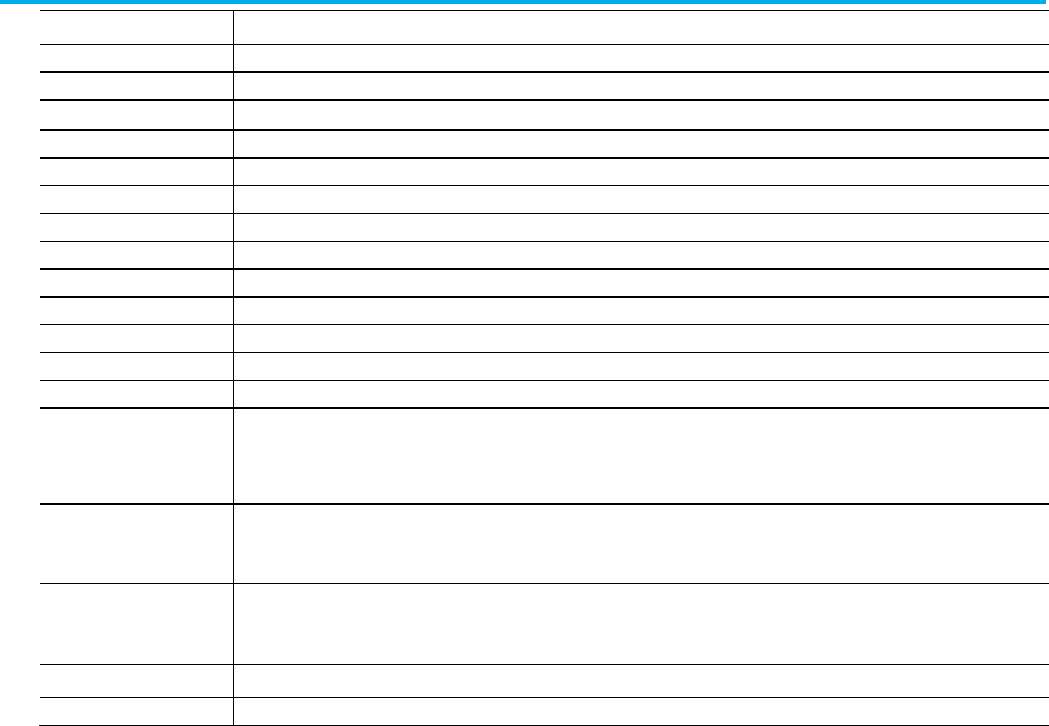

Datatype component introduction........................................................... 67

Datatype component ................................................................................. 67

L5X datatype structure ........................................................................ 67

L5K datatype structure......................................................................... 67

Datatype elements................................................................................ 67

Datatype attributes ............................................................................. 68

Datatype member ...................................................................................... 68

L5X datatype member structure ........................................................ 68

L5K datatype member structure .........................................................69

Datatype member elements ................................................................69

Datatype member attributes ...............................................................69

Bit members ........................................................................................ 70

Datatype guidelines.................................................................................... 71

Datatype component examples ................................................................. 71

Chapter 4

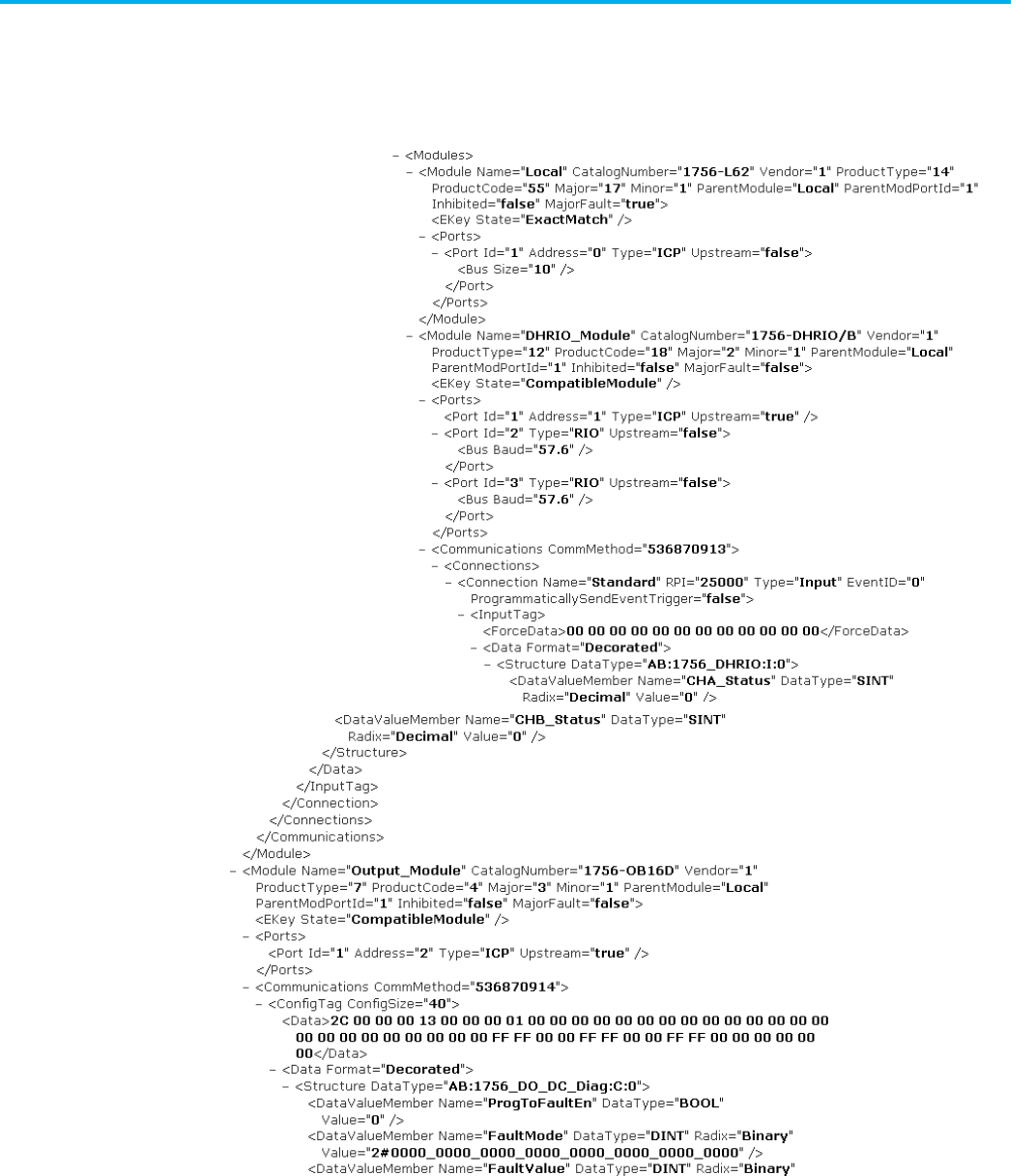

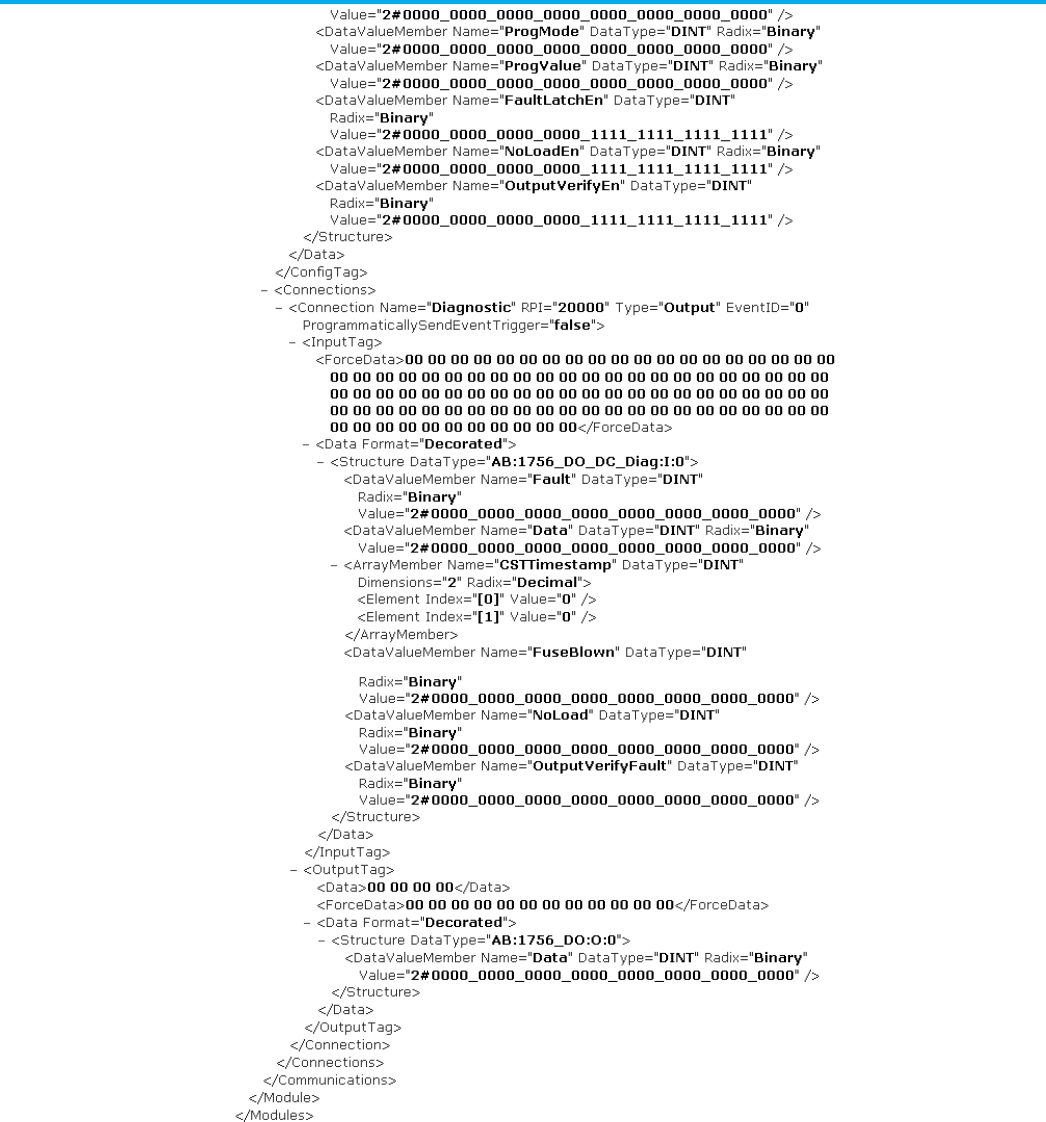

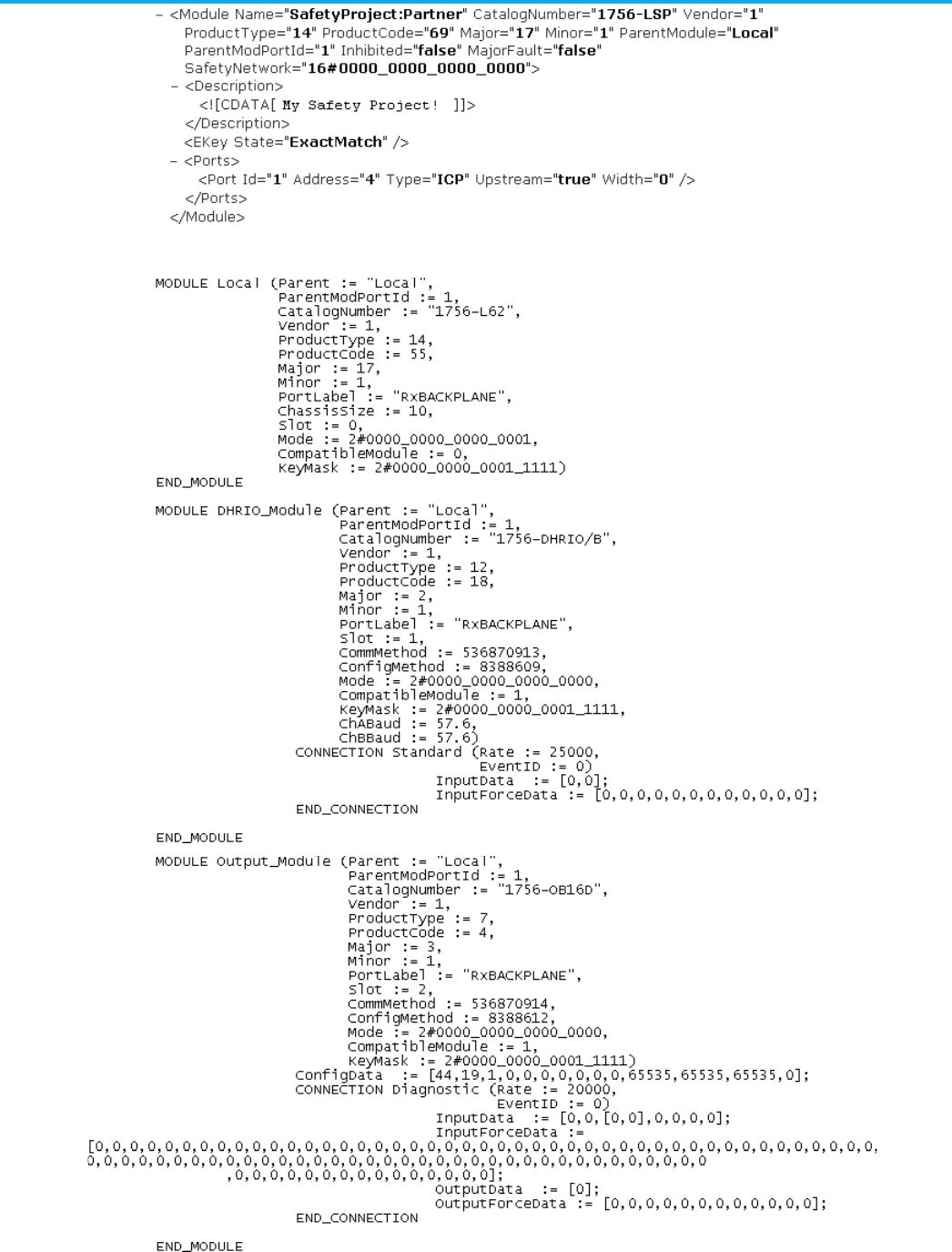

Module component introduction ............................................................. 73

Module component .................................................................................... 73

L5X module structure .......................................................................... 73

L5K MODULE structure....................................................................... 74

Module elements .................................................................................. 74

Module attributes ................................................................................. 74

Module attributes in a safety controller system....................................... 77

Module connection.....................................................................................78

L5X connection structure ....................................................................78

L5K CONNECTION structure .............................................................78

Connection elements ........................................................................... 79

Module connection attributes ............................................................. 79

Module connection attributes in a safety controller system ........... 80

Module guidelines ..................................................................................... 80

Module component examples ................................................................... 81

Chapter 5

Add-On Instruction component introduction ........................................ 85

Add-On Instruction component ............................................................... 85

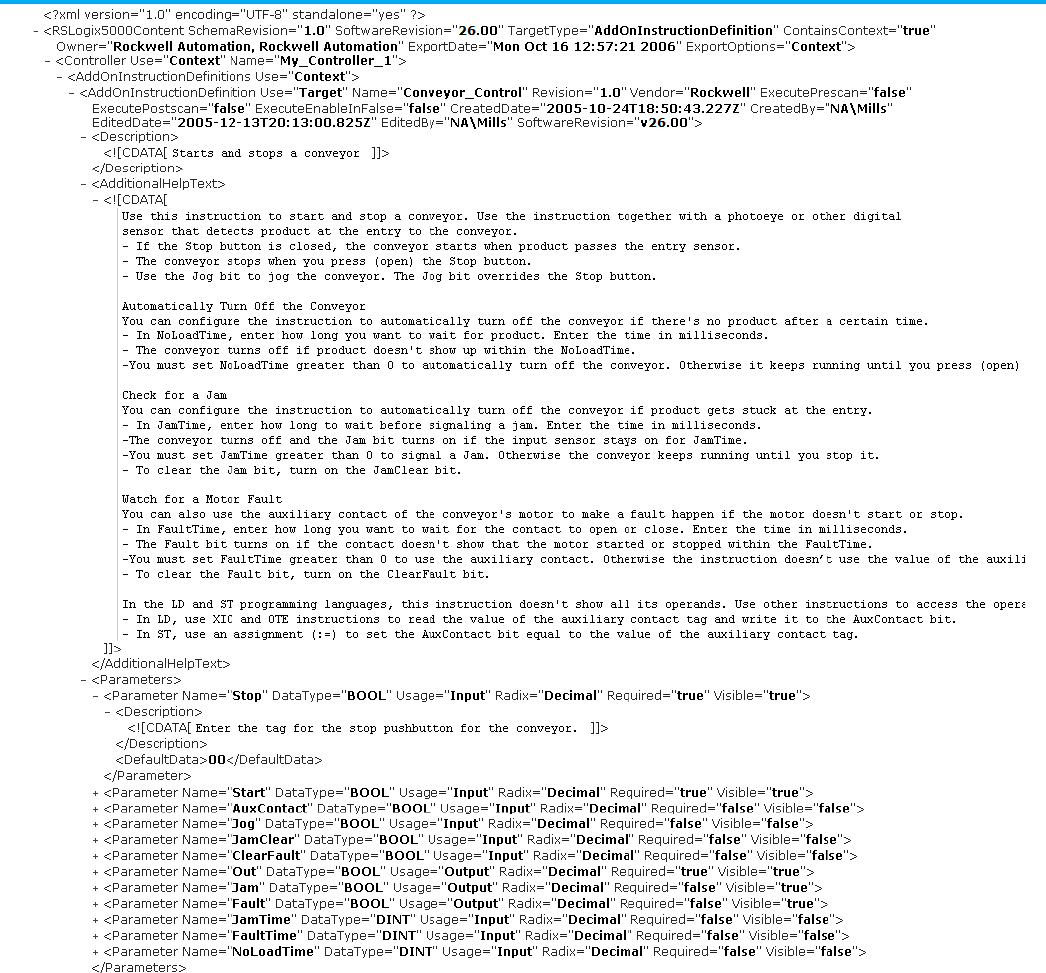

L5X AddOnInstructionDefinition Structure ..................................... 85

L5K ADD_ON_INSTRUCTION_DEFINITION structure ................. 86

Add-On Instruction elements ............................................................ 86

Add-On Instruction attributes ............................................................87

Define a Datatype component

Define a module component

Define an Add-On Instruction

component

Table of Contents

Publication 1756-RM014B-EN-P - November 2023 7

Routines in Add-On Instructions .......................................................87

Parameters ................................................................................................. 88

L5X parameters structure ................................................................... 88

L5K parameters structure ................................................................... 89

Parameter elements ............................................................................ 90

Parameters attributes .......................................................................... 91

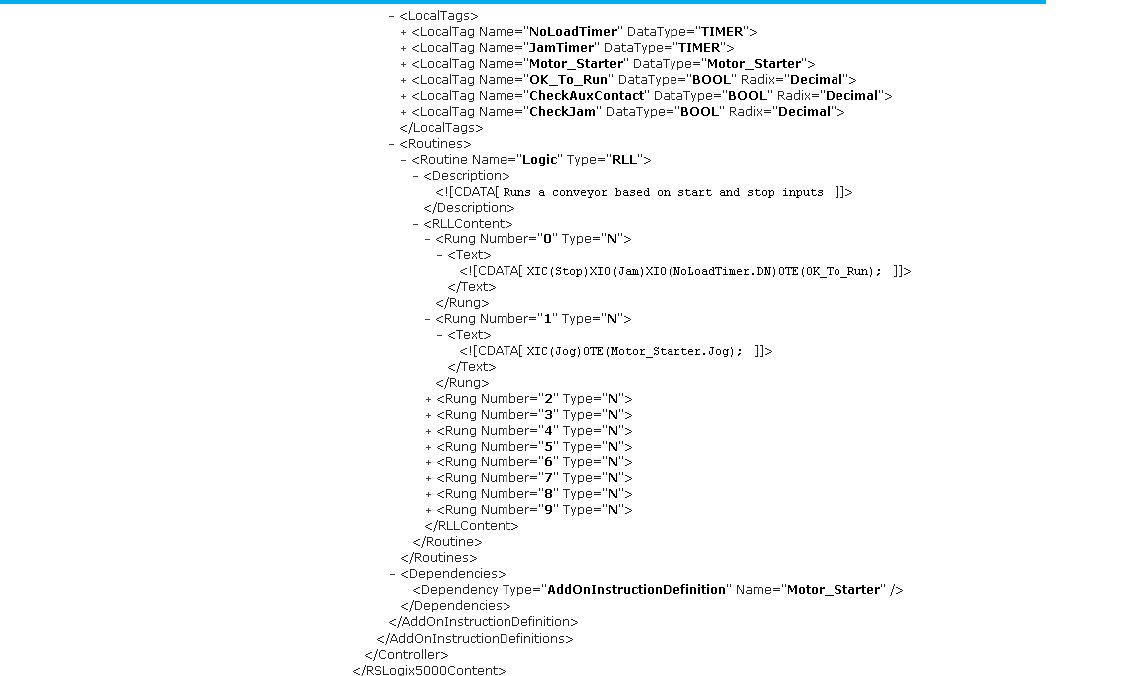

Signature history ....................................................................................... 92

L5X SignatureHistory structure ........................................................ 92

L5K HISTORY_ENTRY structure ........................................................ 93

History entry attributes ....................................................................... 93

Local tags ..................................................................................................... 93

L5X LocalTags structure ...................................................................... 93

L5K LOCAL_TAGS structure ................................................................94

Local tag attributes...............................................................................94

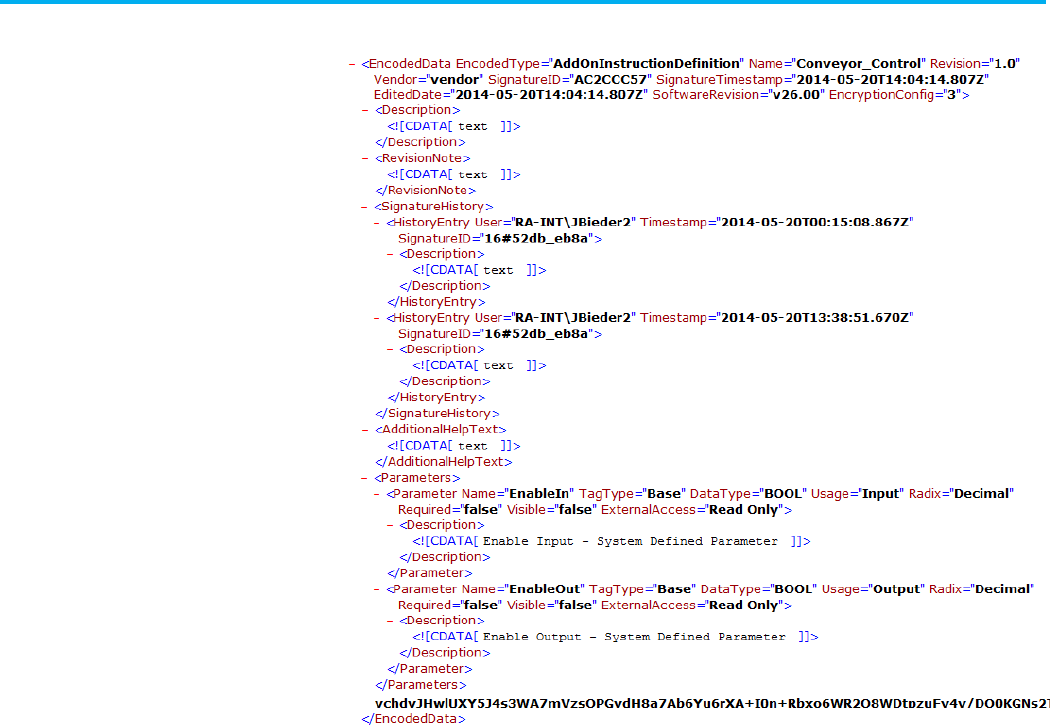

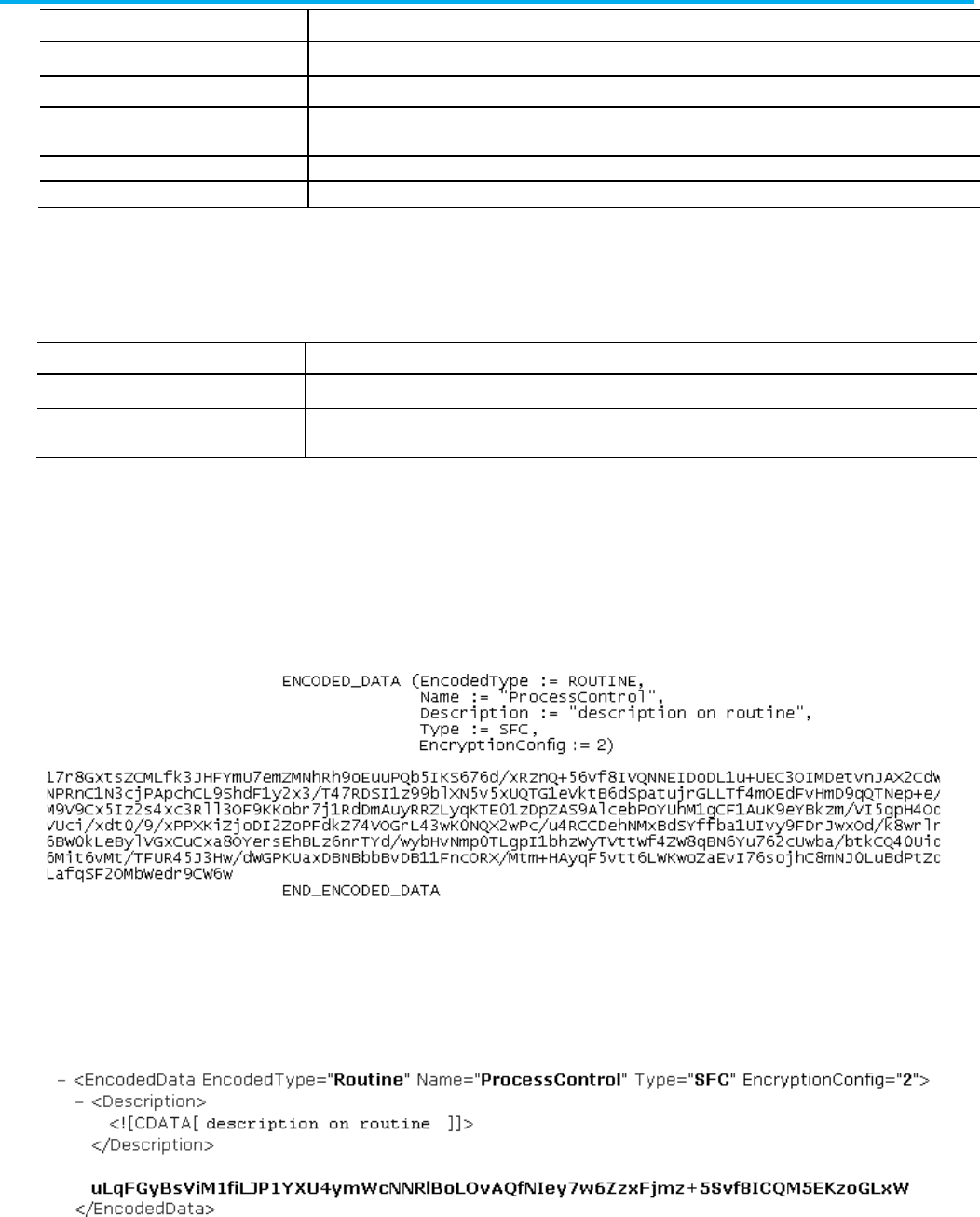

Encoded/Unencoded Add-On Instructions ............................................. 95

L5X EncodedData Structure................................................................ 95

L5K ENCODED_DATA Structure........................................................ 95

Encoded data attributes ...................................................................... 95

Encoded Information elements ..........................................................96

Encoded key attributes ........................................................................96

Encoded content attributes .................................................................96

L5X Encoded Add-On Instruction example ....................................... 97

L5K Encoded Add-On Instruction example ....................................... 97

Add-On Instruction Guidelines................................................................ 98

L5X unencoded AddOnInstruction definition example .................. 98

L5K unencoded ADD_ON_INSTRUCTION _DEFINITION example

............................................................................................................ 100

L5X unencoded safety AddOnInstruction definition example ...... 102

L5K unencoded safety ADD_ON_INSTRUCTION _DEFINITION

example ............................................................................................... 102

Chapter 6

Tag component introduction .................................................................. 105

Tag component ........................................................................................ 105

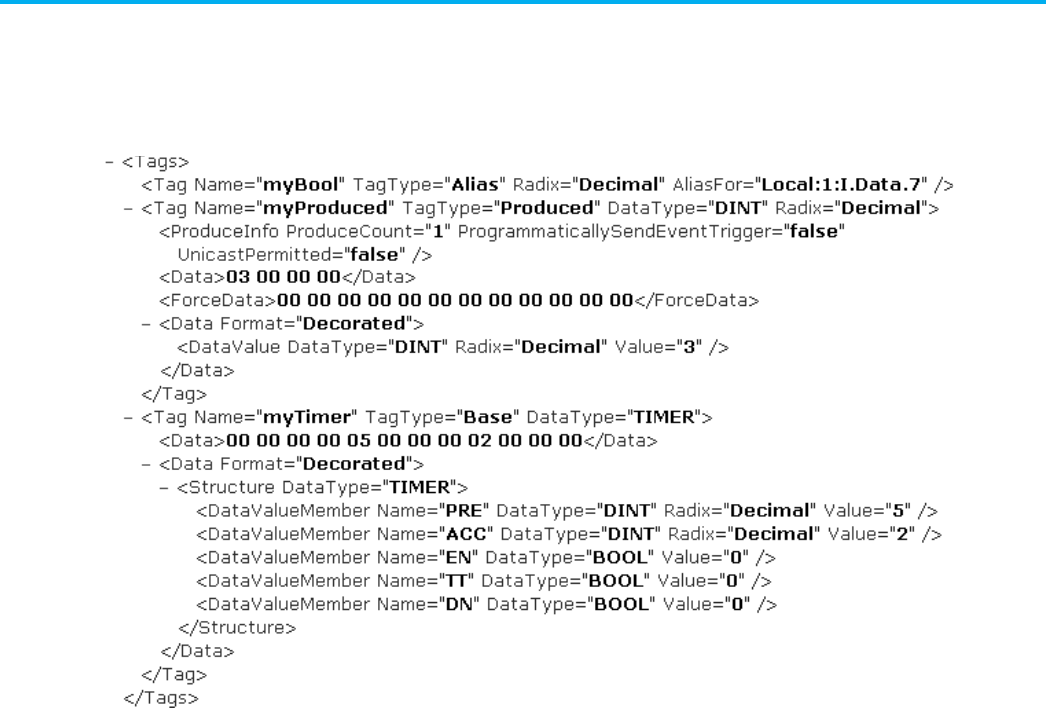

L5X tag structure ................................................................................ 105

L5K TAG structure .............................................................................. 106

Tag elements ....................................................................................... 106

Tag attributes .....................................................................................108

Produced tag attributes ..................................................................... 110

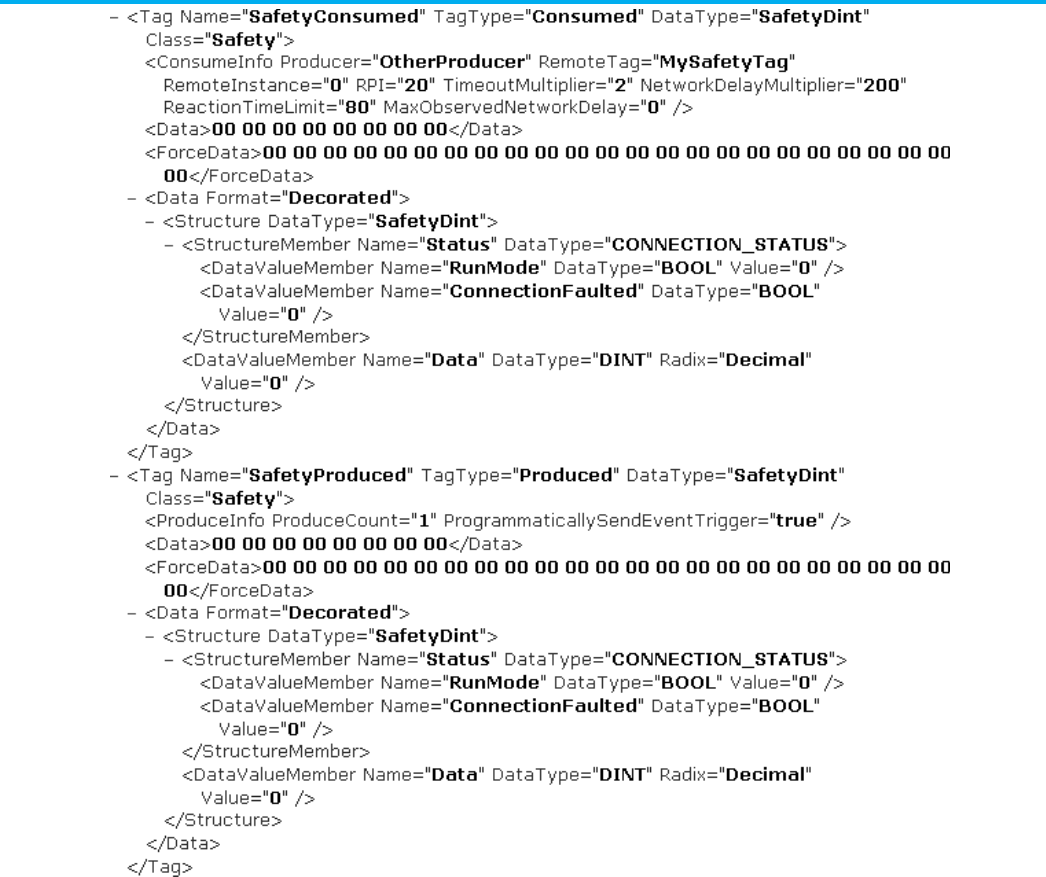

Consumed tag attributes ................................................................... 110

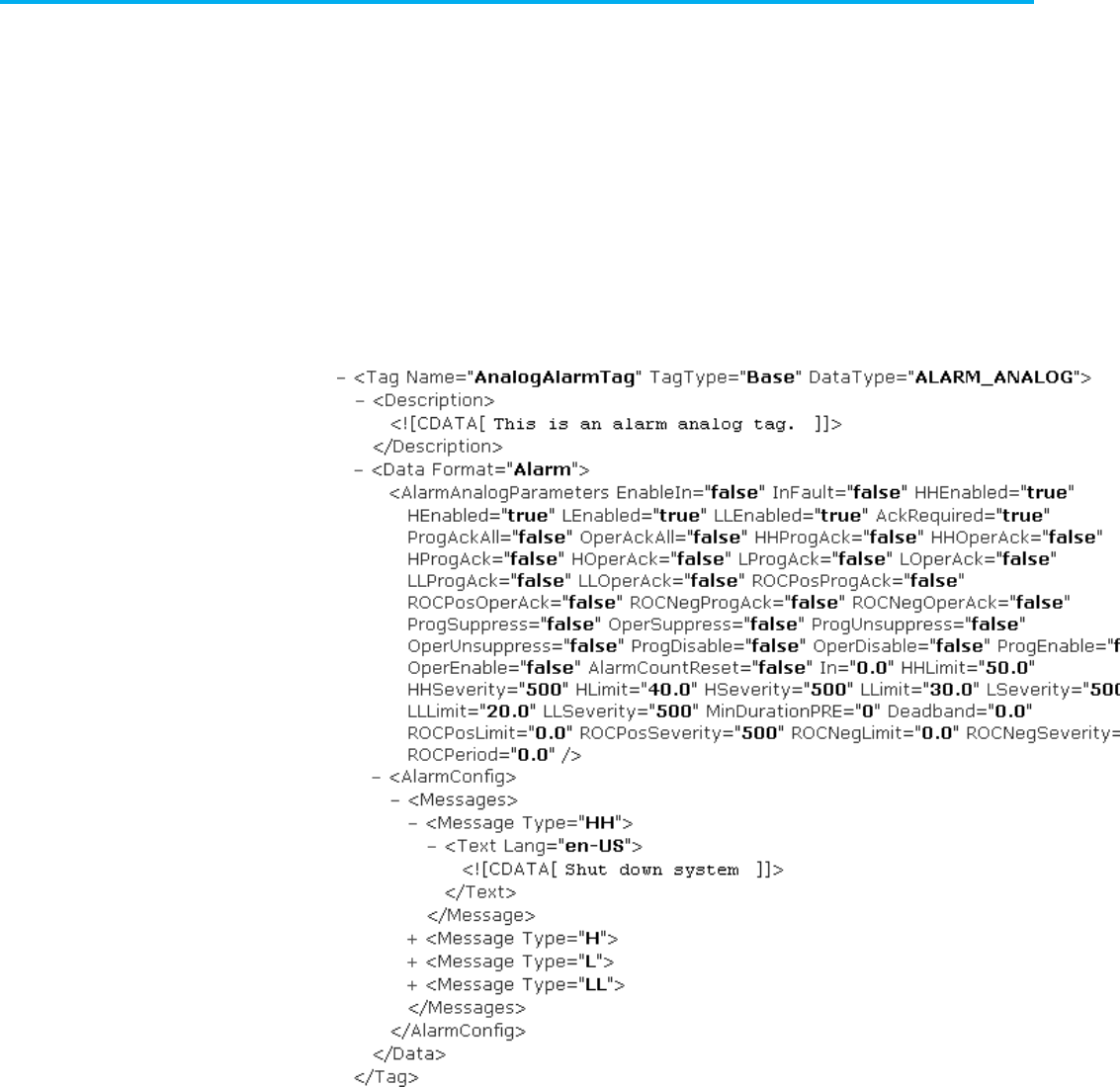

ALARM_ANALOG tag ............................................................................... 110

L5X tag structure for ALARM_ANALOG tag ..................................... 111

Define a tag component

Table of Contents

8 Publication 1756-RM014B-EN-P - November 2023

L5K tag structure for ALARM_ANALOG tag ..................................... 111

ALARM_ANALOG tag attributes ........................................................ 111

ALARM_DIGITAL tag ................................................................................ 113

L5X tag structure for ALARM_DIGITAL tag ..................................... 113

L5K tag structure for an ALARM_DIGITAL tag ................................ 113

ALARM_DIGITAL tag attributes ........................................................ 113

L5X AlarmConfig structure ......................................................................114

AlarmConfig elements ........................................................................115

L5K ANALOG_ALARM message structure ........................................115

ALMMSG elements .............................................................................115

MESSAGE tag ............................................................................................115

L5X message structure ....................................................................... 116

L5K MESSAGE structure ................................................................... 116

Message tag attributes ....................................................................... 116

AXIS_CIP_DRIVE, AXIS_CONSUMED, AXIS_GENERIC_DRIVE,

AXIS_SERVO, AXIS_SERVO_DRIVE, or AXIS_VIRTUAL Tag..............117

L5X axis structure ...............................................................................117

L5K AXIS TAG structure .....................................................................117

Axis tag attributes ...............................................................................117

COORDINATE_SYSTEM tag ................................................................... 128

L5X CoordinateSystem structure ..................................................... 128

L5K COORDINATE_SYSTEM structure ........................................... 129

Coordinate system tag attributes ..................................................... 129

MOTION_GROUP Tag ............................................................................. 130

L5X MotionGroup structure .............................................................. 130

L5K MOTION_GROUP structure ...................................................... 130

Motion Group Tag attributes ............................................................ 130

HMIBC tag ................................................................................................. 131

L5X HMIBC structure ......................................................................... 131

L5K HMIBC structure ......................................................................... 131

HMIBC attributes ............................................................................... 131

SAFETY tag................................................................................................. 131

L5X safety structure ............................................................................ 131

L5K SAFETY structure ........................................................................ 132

Safety tag attributes ........................................................................... 132

Tag initial values ....................................................................................... 132

L5X initial tag value............................................................................ 133

L5K initial TAG value .......................................................................... 133

Add-On Instruction tag values .......................................................... 133

Add-On Instruction tag values example ........................................... 134

Tag guidelines ........................................................................................... 134

Tag initial values examples ...................................................................... 135

Table of Contents

Publication 1756-RM014B-EN-P - November 2023 9

Chapter 7

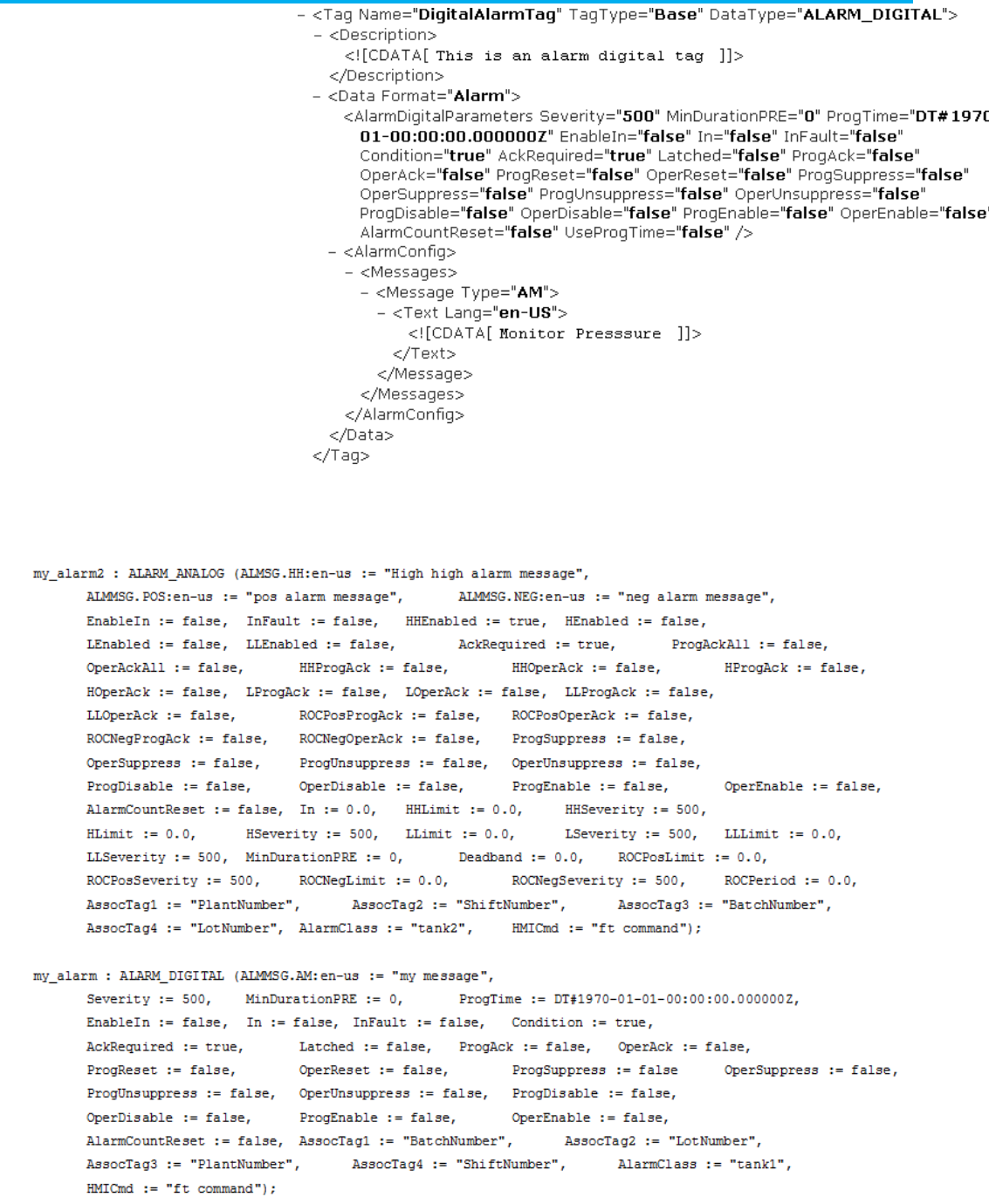

Tag-based alarms introduction ............................................................... 141

Tag-based alarms ...................................................................................... 141

L5X Tag-based alarm structure .......................................................... 141

L5K Tag-based alarm structure ......................................................... 142

Tag-based alarm objects .................................................................... 145

Tag-based alarm definitions.................................................................... 148

L5X Tag-based alarm definition structure ....................................... 149

L5K Tag-based alarm definition structure ....................................... 150

Tag-based alarm definition objects .................................................. 150

Chapter 8

Program component introduction .......................................................... 153

Program component ................................................................................. 153

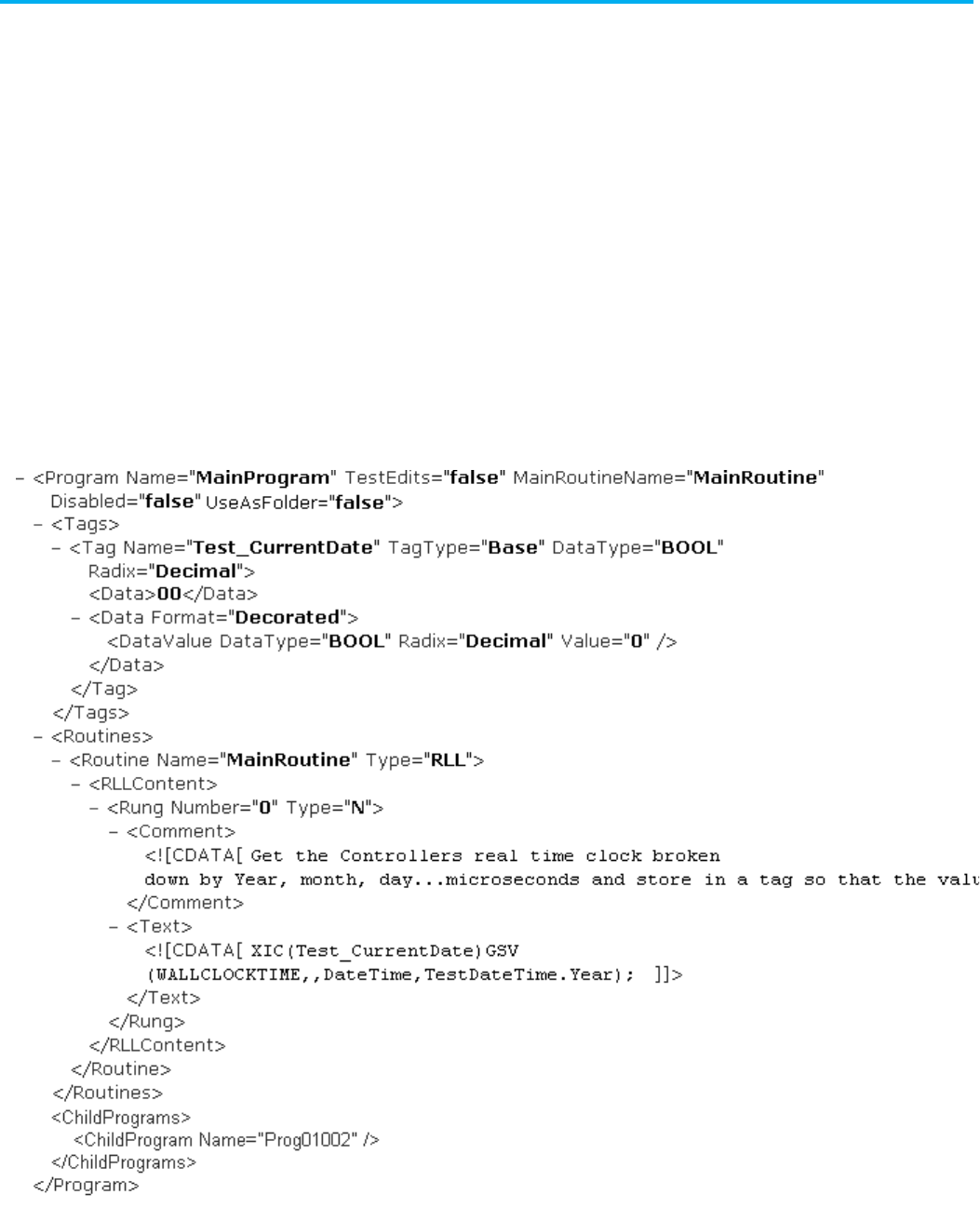

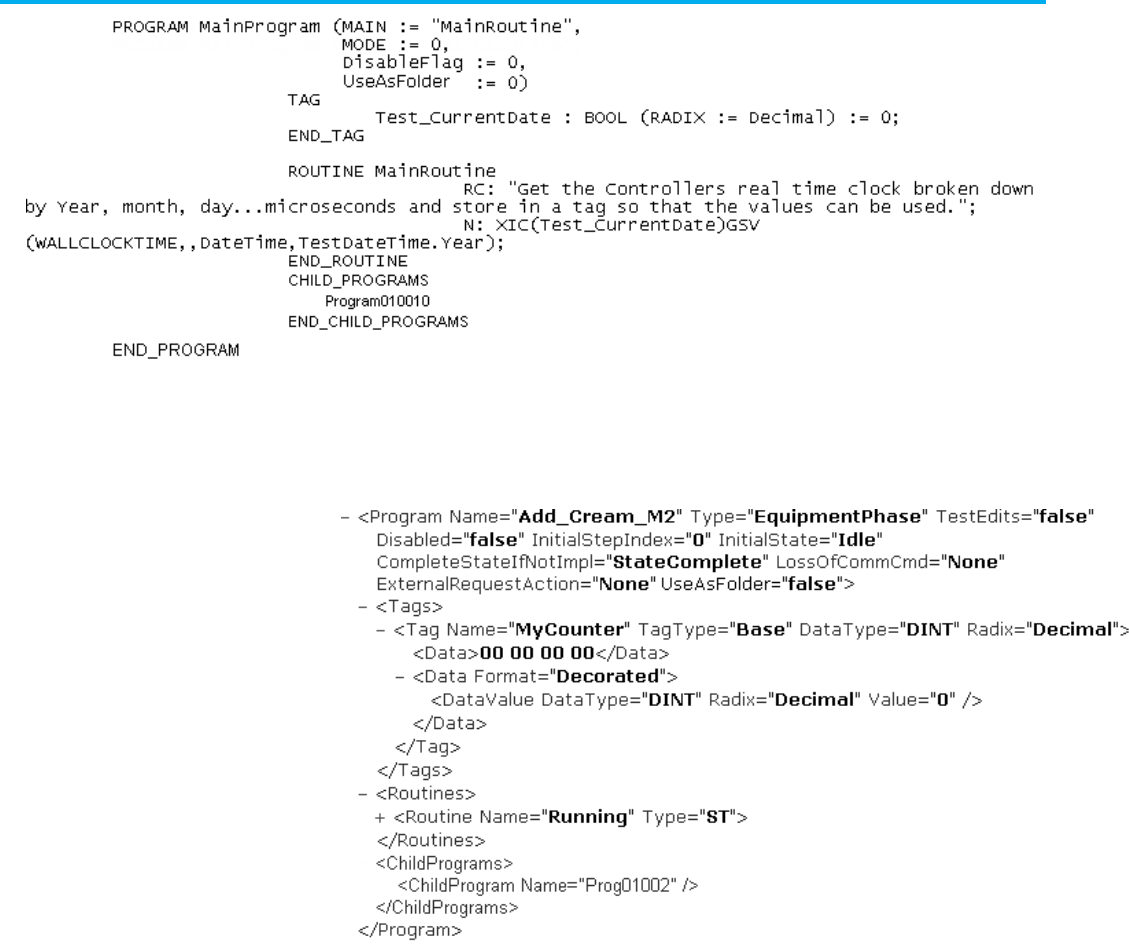

L5X program structure ...................................................................... 153

Program elements .............................................................................. 154

Program attributes ............................................................................. 154

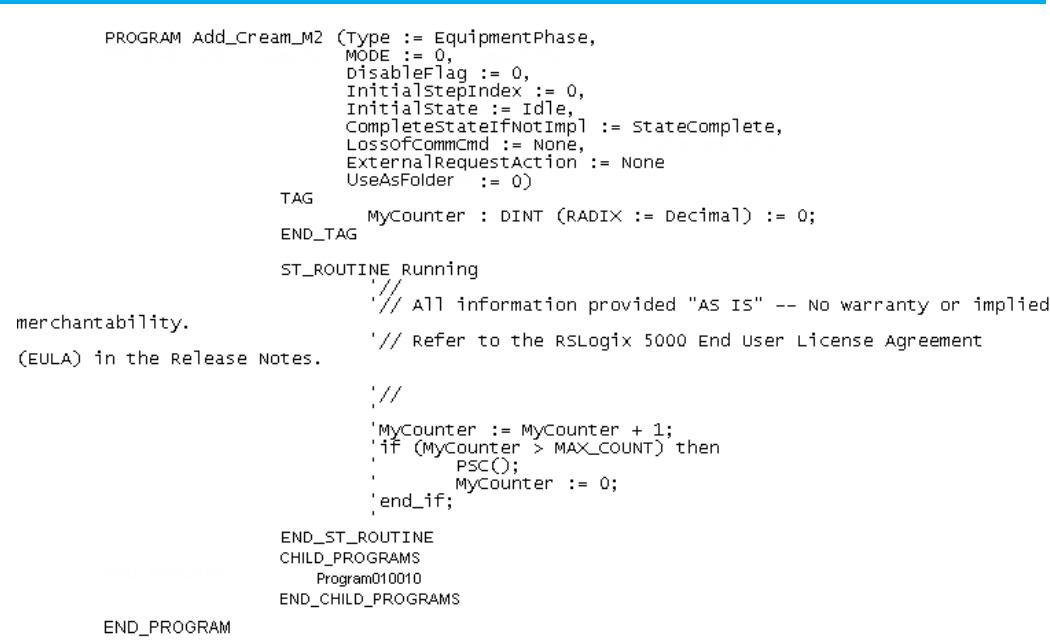

Program attributes for EquipmentPhase programs ....................... 155

Program attributes for Sequence programs .................................... 156

Child program component ...................................................................... 156

L5K CHILD_PROGRAM structure .................................................... 156

L5X child program structure ............................................................. 157

Child program attributes ................................................................... 157

Child program guidelines .................................................................. 157

Encoded/Unencoded routines ................................................................ 157

L5X EncodedData Structure.............................................................. 157

L5K ENCODED_DATA Structure...................................................... 158

Encoded Data Elements .................................................................... 158

Encoded Information elements ........................................................ 158

Encoded key attributes ...................................................................... 158

Encoded content attributes ............................................................... 159

L5K source protected routine example ............................................. 159

L5X source-protected routine example ............................................ 159

Program guidelines .................................................................................. 159

Program guidelines examples ................................................................. 160

Chapter 9

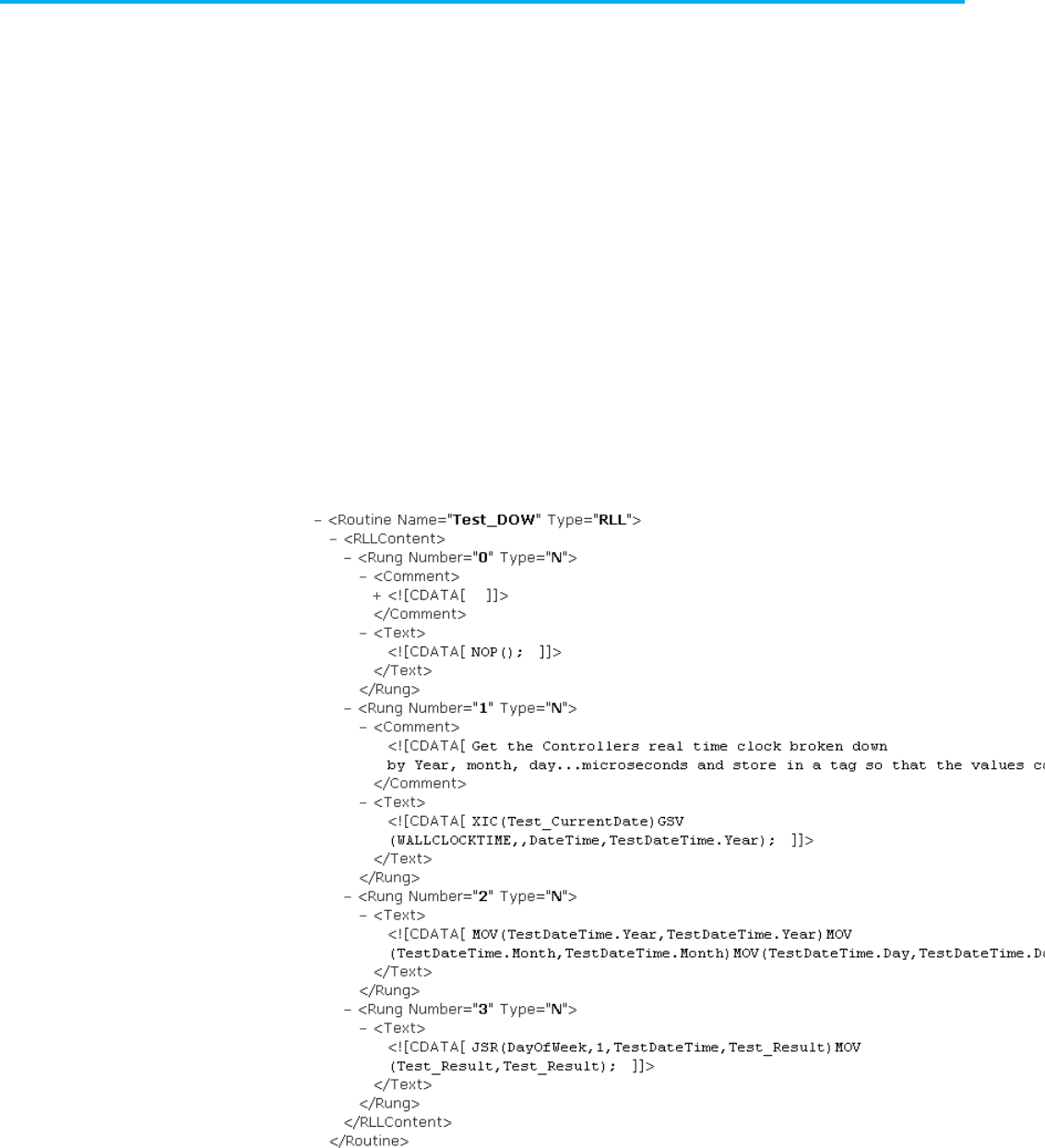

Ladder logic routine introduction ........................................................... 163

Ladder logic routine.................................................................................. 163

L5X ladder logic routine structure .................................................... 163

L5K Ladder Logic ROUTINE structure ............................................. 163

Ladder logic routine elements........................................................... 163

Define a tag-based alarm or

alarm definition

Define a program component

Define a ladder logic routine

Table of Contents

10 Publication 1756-RM014B-EN-P - November 2023

RLL Routine attributes ...................................................................... 164

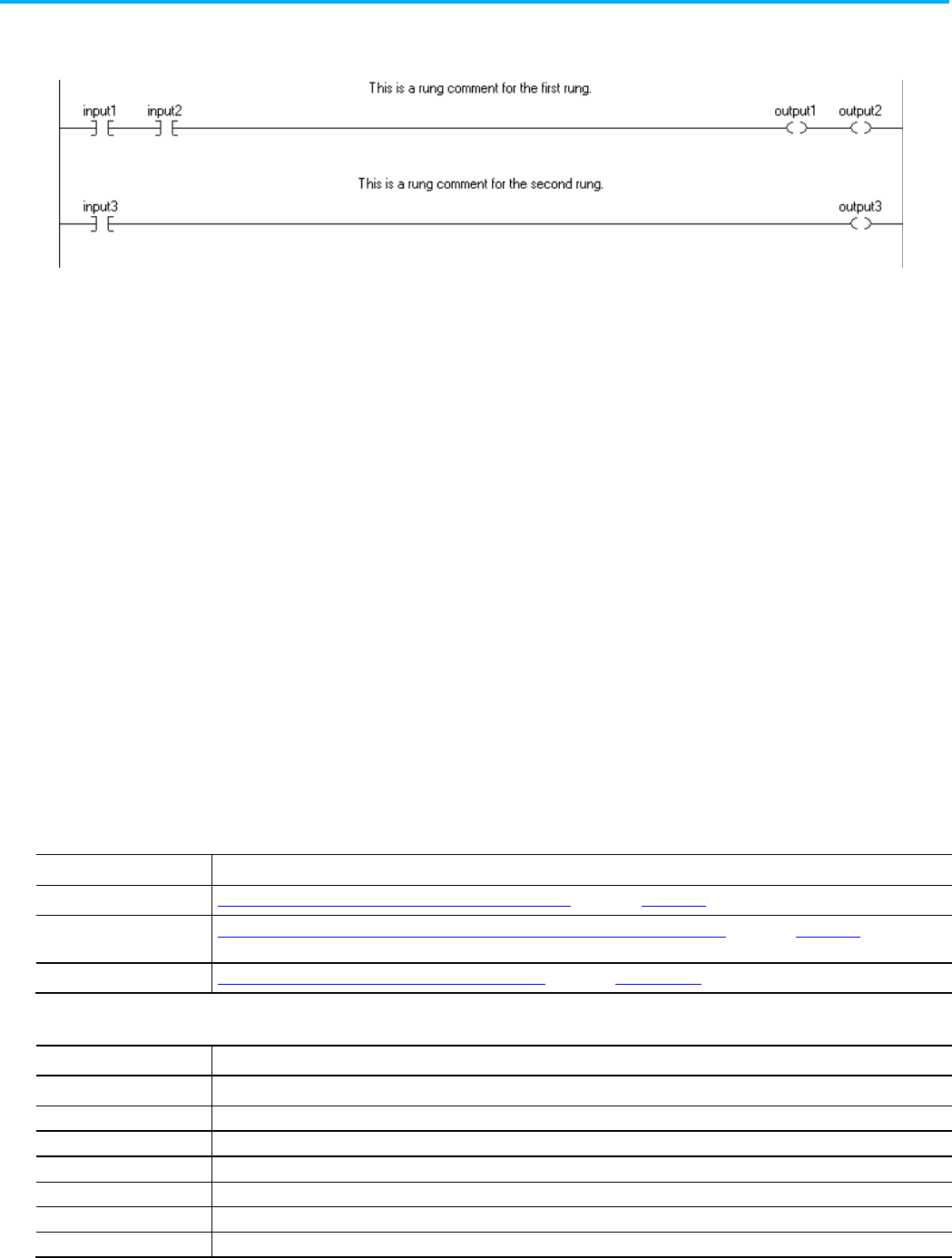

Rung logic ................................................................................................. 164

L5X rung structure ............................................................................. 164

L5K RUNG structure .......................................................................... 164

Rung elements .................................................................................... 165

Rung attributes .................................................................................. 165

Rung guidelines ........................................................................................ 165

Single or simultaneous branches ............................................................ 165

L5X branch structure ......................................................................... 166

L5K BRANCH structure ..................................................................... 166

L5X Examples ........................................................................................... 166

L5K examples ............................................................................................ 167

Neutral text for ladder instructions ........................................................ 167

Chapter 10

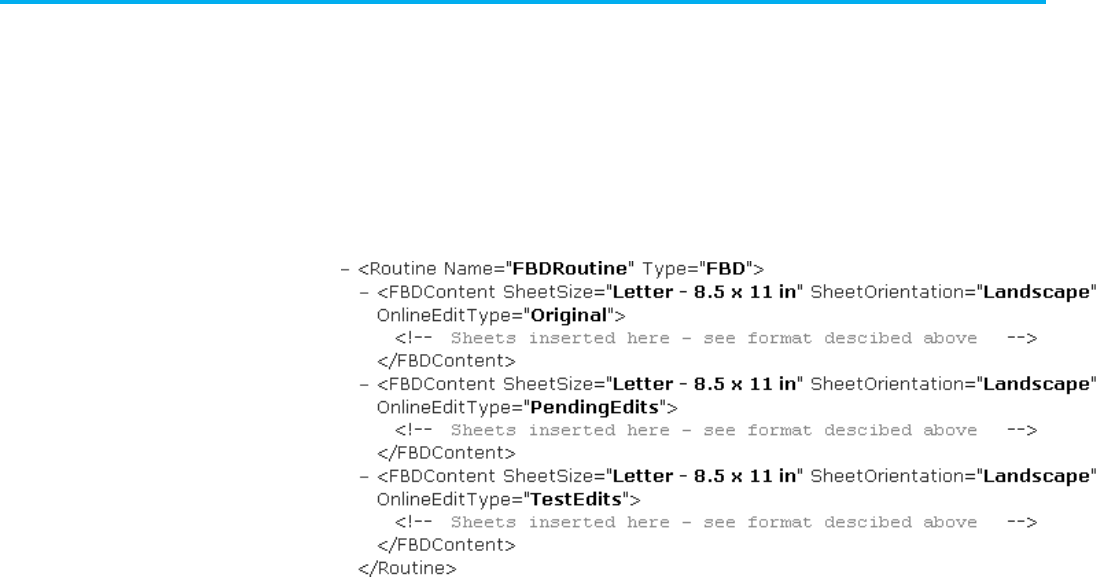

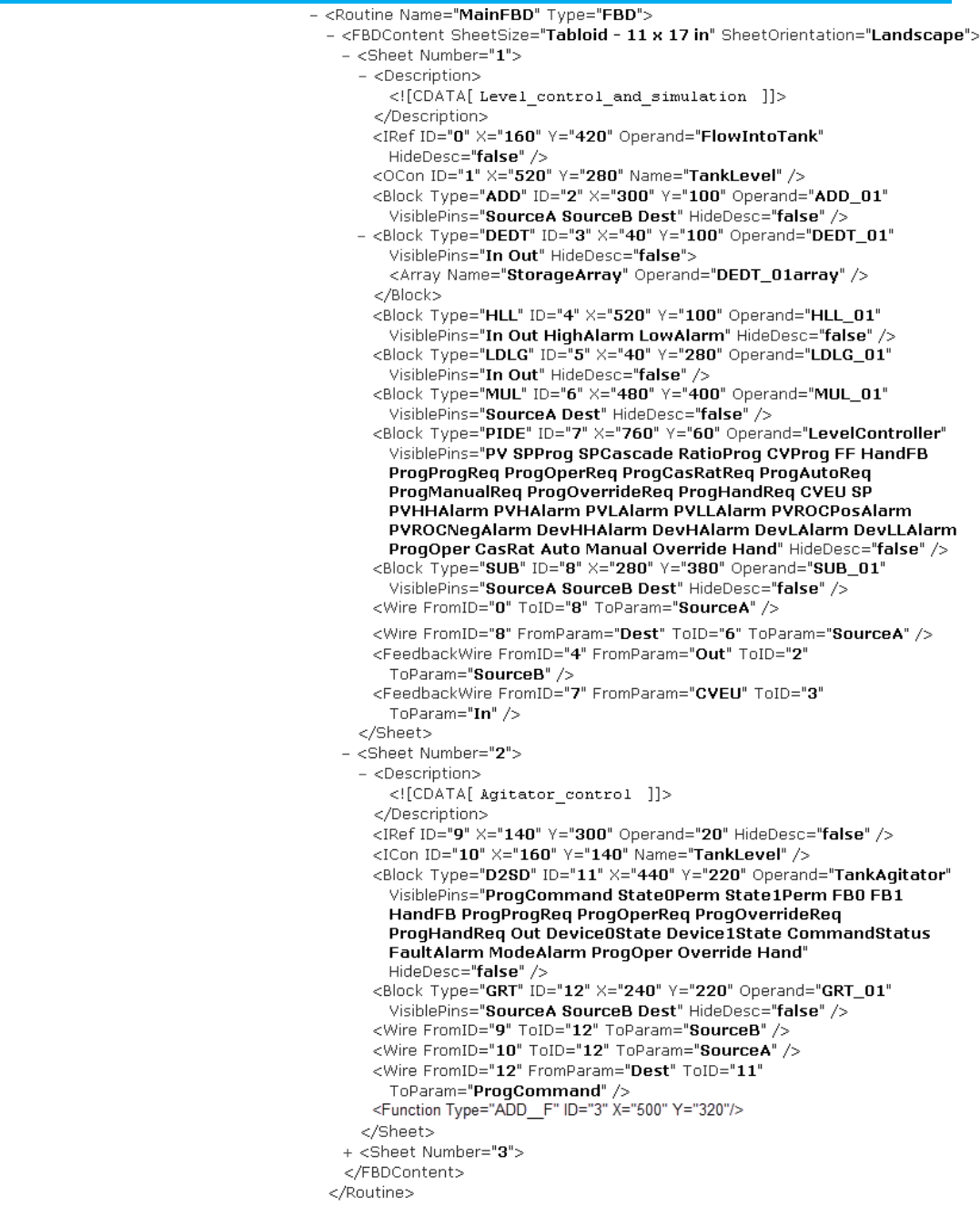

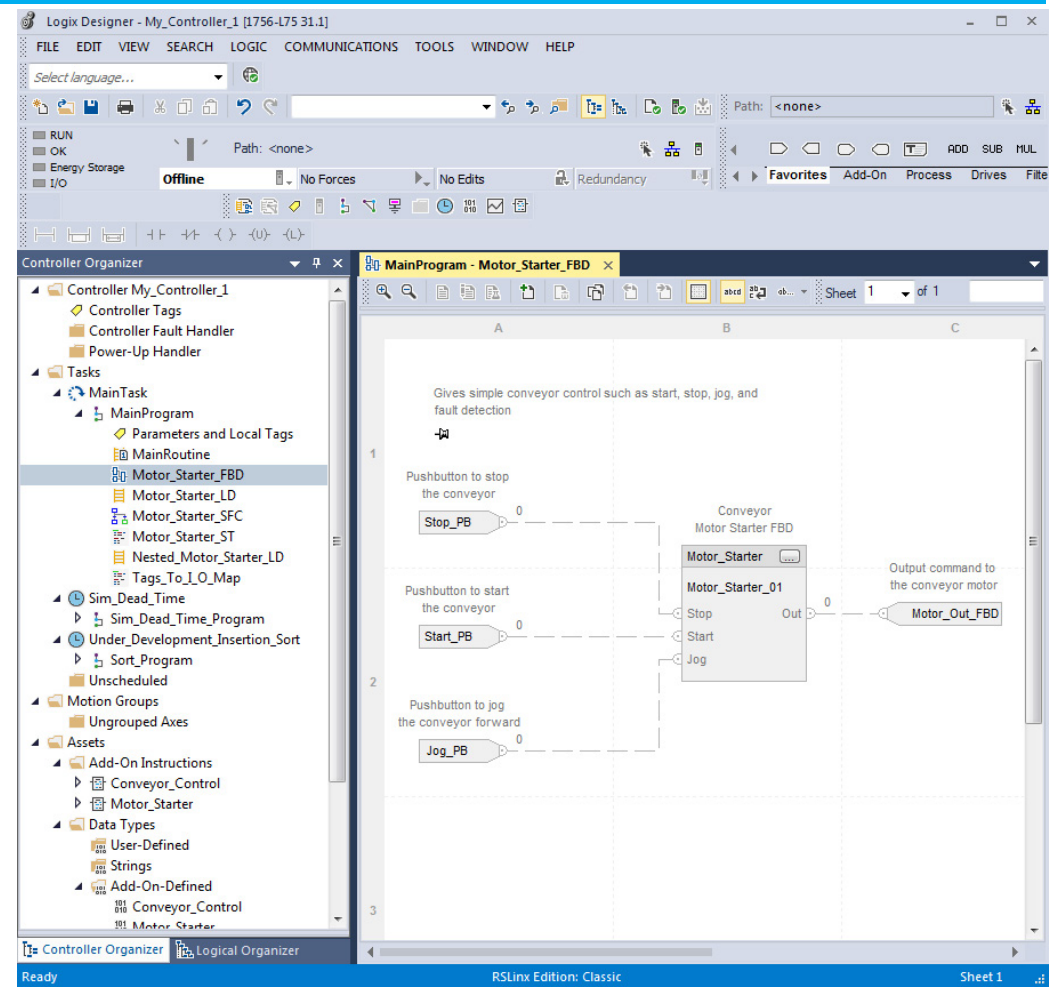

Function block diagram routine introduction ....................................... 175

Function BlockDiagram Routine ............................................................. 175

L5X function block diagram routine structure ................................. 175

L5K Function Block FBD_ROUTINE structure ................................ 175

Function block routine elements ...................................................... 176

FBD_routine attributes...................................................................... 176

Sheet .......................................................................................................... 176

L5X sheet structure ............................................................................ 176

L5K SHEET structure ......................................................................... 177

Sheet elements ................................................................................... 177

Sheet attributes .................................................................................. 178

Sheet guidelines ................................................................................. 178

Export function block logic while editing online ................................... 179

Input and output references ...................................................................180

L5X IREF and OREF structure ..........................................................180

L5K IREF and OREF structure ..........................................................180

Reference attributes ...........................................................................180

Reference guidelines .......................................................................... 181

Input and output connectors .................................................................. 181

L5X ICON and OCON structure ........................................................ 181

L5K ICON and OCON structure ........................................................ 181

Connector attributes .......................................................................... 181

Connector guidelines ......................................................................... 181

Blocks ........................................................................................................ 182

L5X block structure ............................................................................ 182

L5K BLOCK structure ......................................................................... 182

Block attributes .................................................................................. 182

Define a function block diagram

routine

Table of Contents

Publication 1756-RM014B-EN-P - November 2023 11

Block guidelines ................................................................................. 183

Functions .................................................................................................. 183

L5X function structure....................................................................... 183

L5K FUNCTION structure ................................................................. 183

Function attributes ............................................................................ 183

Add-On instructions ................................................................................ 184

L5X Add-On Instruction structure ................................................... 184

L5K ADD_ON_INSTRUCTION structure ......................................... 184

Add-On Instruction Attributes ......................................................... 184

Add-On Instruction Guidelines ........................................................ 185

JSR ............................................................................................................. 185

L5X JSR structure ............................................................................... 185

L5K JSR structure ............................................................................... 185

JSR attributes...................................................................................... 185

JSR guidelines ..................................................................................... 186

SBR ............................................................................................................ 186

L5X SBR structure .............................................................................. 186

L5K SBR structure .............................................................................. 186

SBR attributes .................................................................................... 186

SBR guidelines.................................................................................... 187

RET ............................................................................................................ 187

L5X RET structure .............................................................................. 187

L5K RET structure .............................................................................. 187

RET attributes .................................................................................... 187

RET guidelines ................................................................................... 188

Wires and feedback wires ........................................................................ 188

L5X wire structure .............................................................................. 188

L5K WIRE structure ........................................................................... 188

Wire attributes ................................................................................... 188

Wire guidelines .................................................................................. 188

Text boxes.................................................................................................. 189

L5X TextBox structure ....................................................................... 189

L5K TEXTBOX structure.................................................................... 189

Text box attributes ............................................................................. 189

Text box guidelines for block sections .............................................. 189

Function block attachments .................................................................... 189

L5X attachment structure.................................................................. 190

L5K ATTACHMENT structure ........................................................... 190

Attachment attributes........................................................................ 190

FBD element attachment guidelines ................................................ 190

Attachments examples ............................................................................. 190

Parameters for function block instructions ........................................... 194

Table of Contents

12 Publication 1756-RM014B-EN-P - November 2023

Chapter 11

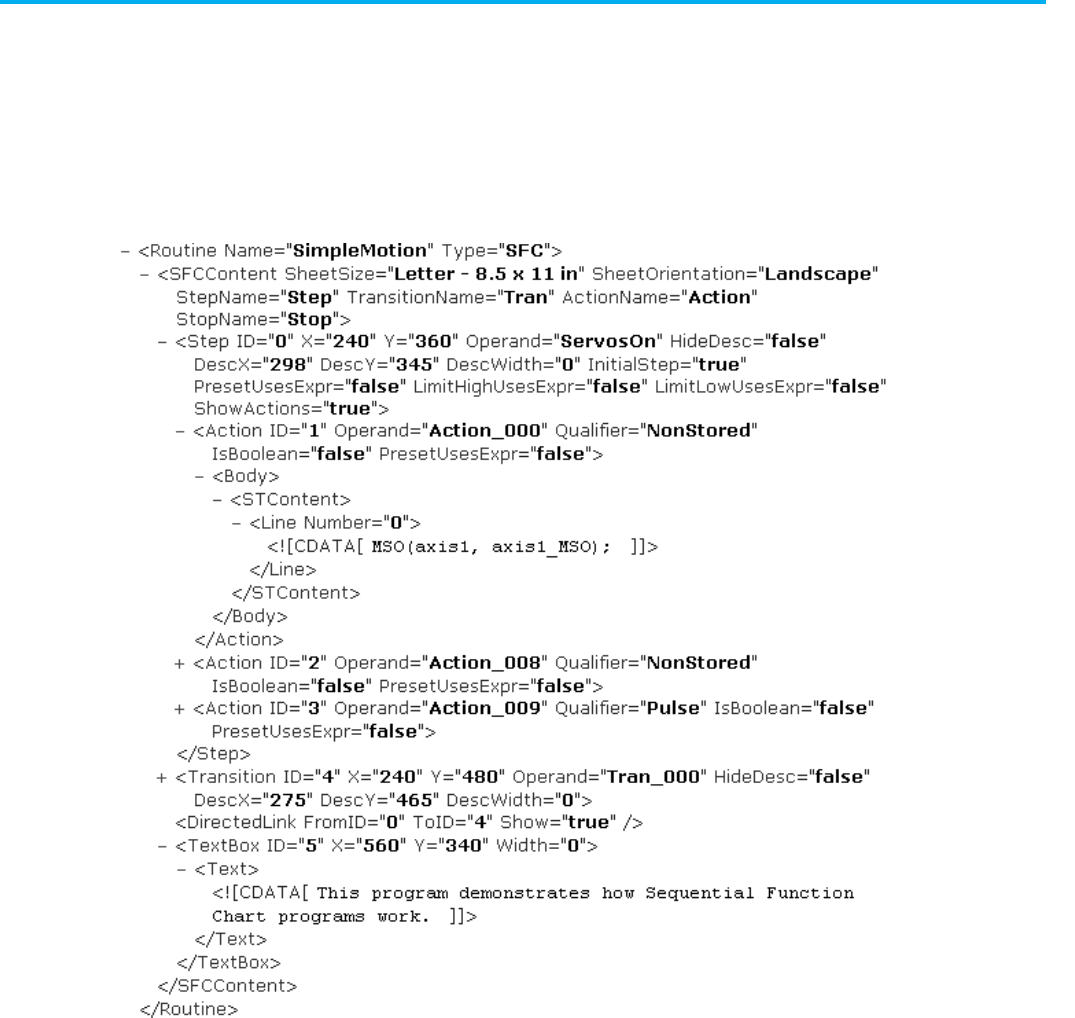

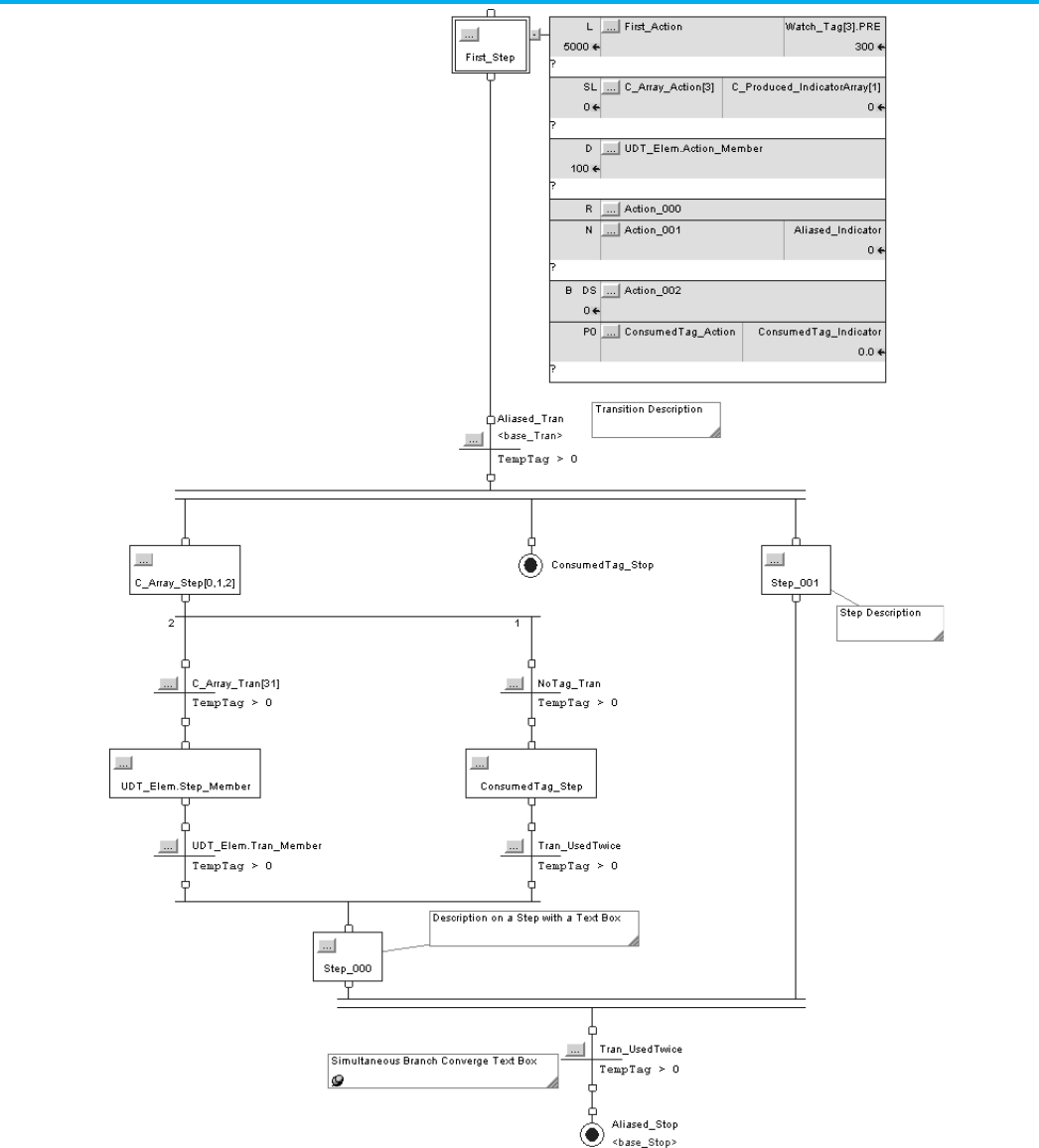

Sequential function chart routine introduction ....................................199

Sequential function chart routine ...........................................................199

L5X sequential function chart structure ...........................................199

L5K sequential function chart SFC_ROUTINE structure .............. 200

Sequential function chart elements................................................. 200

SFC_Routine attributes .................................................................... 200

Export sequential function chart logic while editing online ................ 201

Steps ......................................................................................................... 203

SFC L5X step structure ..................................................................... 203

SFC L5K STEP structure ................................................................... 203

Step elements .................................................................................... 203

SFC step attributes ............................................................................ 204

Preset ........................................................................................................ 204

L5X preset structure .......................................................................... 204

L5K PRESET structure ...................................................................... 204

Limit high ................................................................................................. 205

L5X limit high structure ................................................................... 205

L5K LIMITHIGH structure ............................................................... 205

Limit low .................................................................................................. 205

L5X limit low structure ..................................................................... 205

L5K LIMITHIGH structure ............................................................... 205

Action list ................................................................................................. 206

L5X Action structure ......................................................................... 206

L5K ACTION structure ...................................................................... 206

Action attributes................................................................................ 206

Transitions ............................................................................................... 207

L5X transition structure ................................................................... 207

L5K TRANSITION structure ............................................................. 207

Transition elements .......................................................................... 207

Transition attributes ......................................................................... 207

Condition ................................................................................................. 208

L5X condition structure .................................................................... 208

L5K CONDITION structure .............................................................. 208

Subroutine calls ....................................................................................... 208

L5X SbrRet structure......................................................................... 208

L5K SBR_RET structure .................................................................... 209

Subroutine attributes ....................................................................... 209

Stops ......................................................................................................... 209

L5X stop structure ............................................................................. 209

L5K STOP structure ........................................................................... 209

Stop attributes ................................................................................... 209

Define a sequential function

chart routine

Table of Contents

Publication 1756-RM014B-EN-P - November 2023 13

SFC routine branches ............................................................................... 210

L5X branch structure ......................................................................... 210

L5K BRANCH structure ..................................................................... 210

Branch attributes ............................................................................... 210

Leg attributes ...................................................................................... 210

SFC directed links..................................................................................... 211

L5X DirectedLink structure ............................................................... 211

L5K DIRECTED_LINK structure ...................................................... 211

Directed link attributes ..................................................................... 211

Directed link guidelines..................................................................... 211

Text boxes.................................................................................................. 211

L5X TextBox structure ....................................................................... 211

L5K TEXTBOX structure.................................................................... 211

Text box attributes ............................................................................. 212

Text box guidelines for directed link blocks .................................... 212

Attachments .............................................................................................. 212

L5X attachment structure.................................................................. 212

L5K ATTACHMENT structure ........................................................... 212

Attachment attributes........................................................................ 212

SFC element attachment guidelines ................................................. 213

SFC attachments examples...................................................................... 213

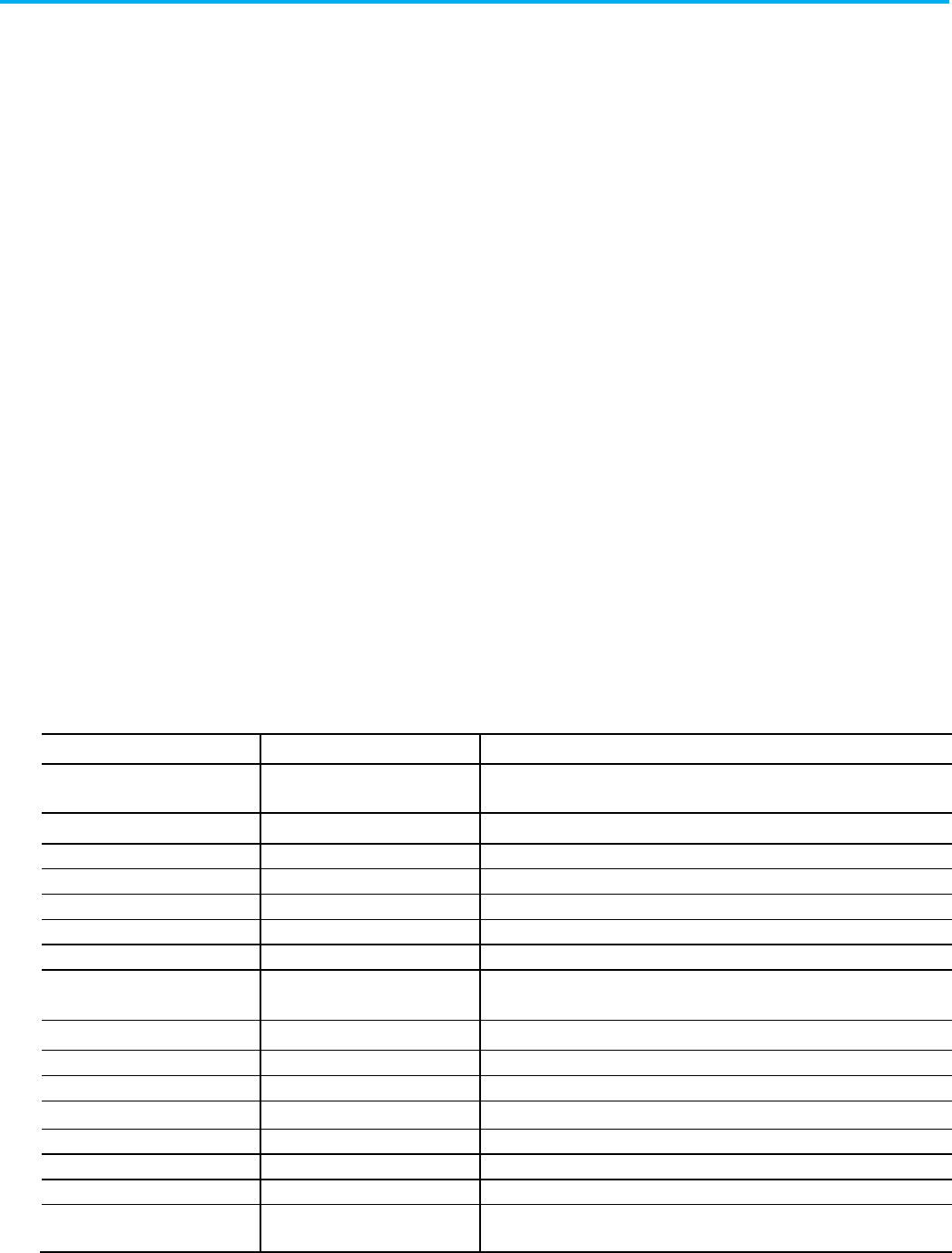

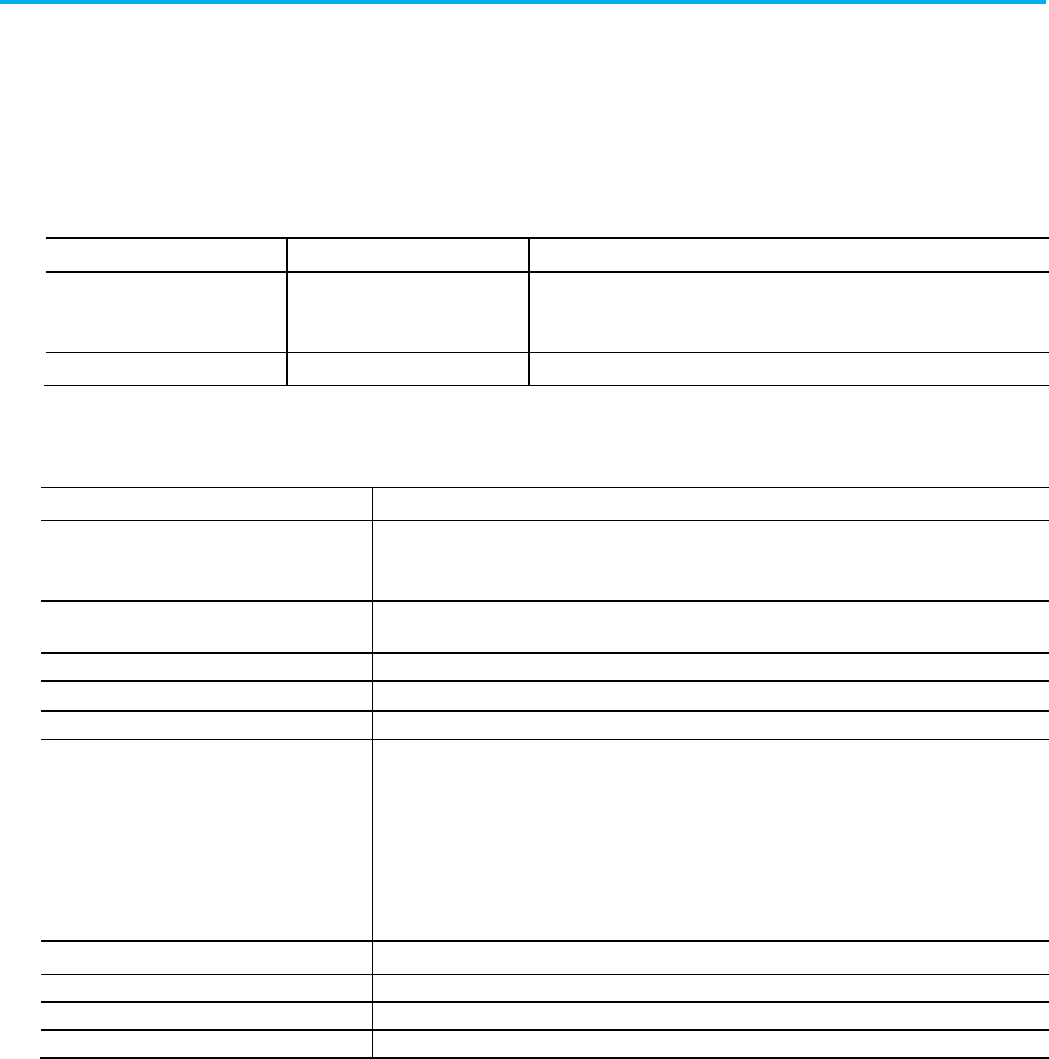

Chapter 12

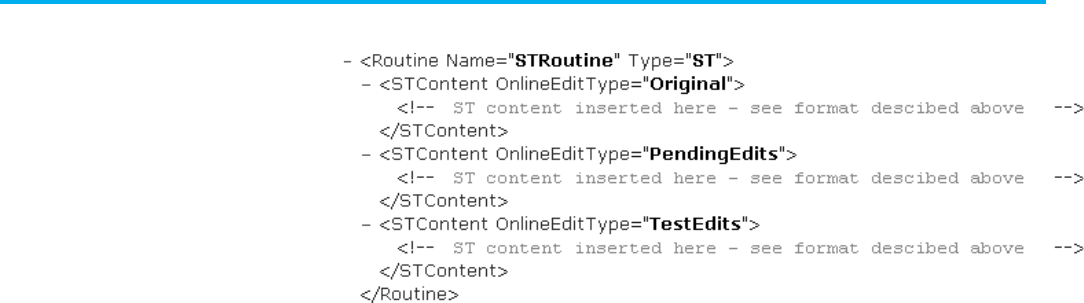

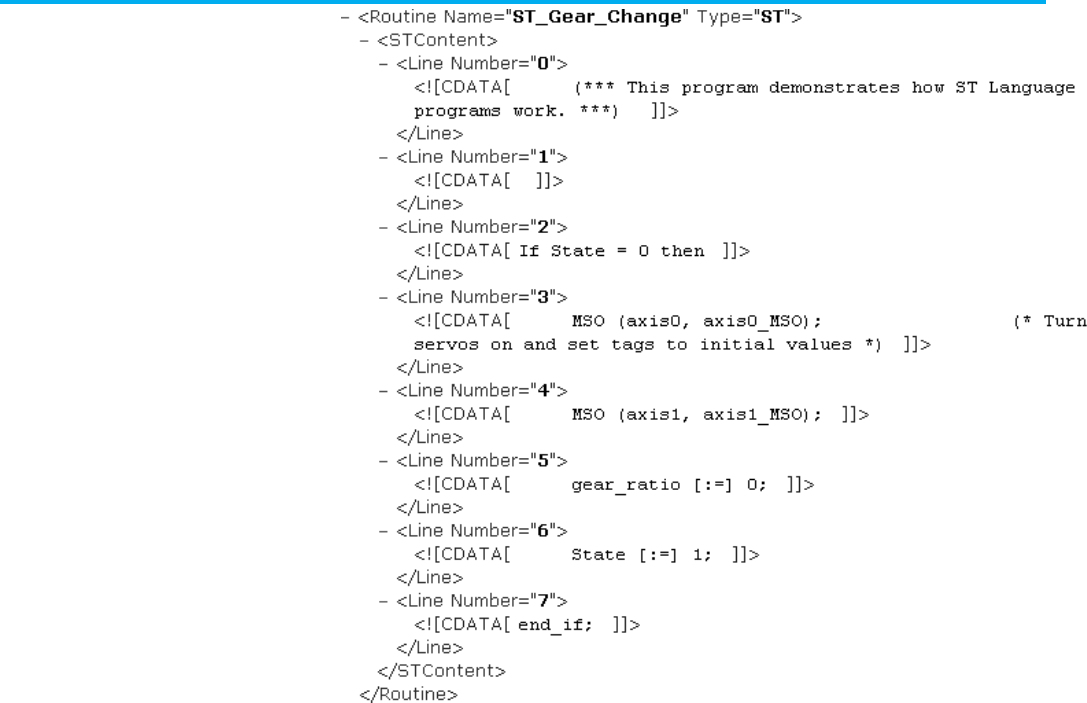

Structured text routine introduction ..................................................... 221

Structured text routine............................................................................ 221

L5X structured text structure ............................................................ 221

L5K structured text ST_ROUTINE structure ................................... 221

Structured Text routine elements..................................................... 221

ST_Routine attributes ....................................................................... 222

Structured text logic ................................................................................ 222

Export structured text logic while editing online .................................. 223

Structured text routine examples .......................................................... 224

Structured text......................................................................................... 226

Chapter 13

Equipment Sequence routine introduction .......................................... 233

Equipment Sequence Routine ................................................................ 233

L5X Equipment Sequence structure ................................................. 233

L5K Equipment Sequence ESQ_ROUTINE structure ..................... 234

Equipment Sequence elements......................................................... 234

ESQ_Routine attributes..................................................................... 234

Steps .......................................................................................................... 235

Define a structured text routine

Define an Equipment Sequence

routine

Table of Contents

14 Publication 1756-RM014B-EN-P - November 2023

Structured text L5X step structure ................................................... 235

Structured text L5K STEP structure ................................................. 235

Structured text step attributes .......................................................... 235

Transitions ................................................................................................ 236

L5X transition structure .................................................................... 236

L5K TRANSITION structure .............................................................. 236

Transition elements ........................................................................... 236

Transition attributes .......................................................................... 237

Stops .......................................................................................................... 237

L5X stop structure .............................................................................. 237

L5K STOP structure ............................................................................ 237

Stop attributes .................................................................................... 237

Equipment Sequence routine branches .................................................238

L5X branch structure .........................................................................238

L5K BRANCH structure .....................................................................238

Branch attributes ...............................................................................238

Leg attributes ...................................................................................... 239

Equipment Sequence directed links ....................................................... 239

L5X DirectedLink structure ............................................................... 239

L5K DIRECTED_LINK structure ...................................................... 239

Directed link attributes ..................................................................... 239

Directed link guidelines..................................................................... 239

Equipment Sequence attachments ........................................................ 240

L5X attachment structure................................................................. 240

L5K ATTACHMENT structure .......................................................... 240

Attachment attributes....................................................................... 240

Equipment Sequence element attachment guidelines .................. 240

Tag configuration .................................................................................... 240

L5X tag configuration structure ...................................................... 240

L5K TAG_CONFIGURATION structure............................................ 241

Tag configuration elements .............................................................. 241

Expression component ............................................................................ 241

L5X expression structure ................................................................... 241

L5K EXPRESSION structure ............................................................. 241

Chapter 14

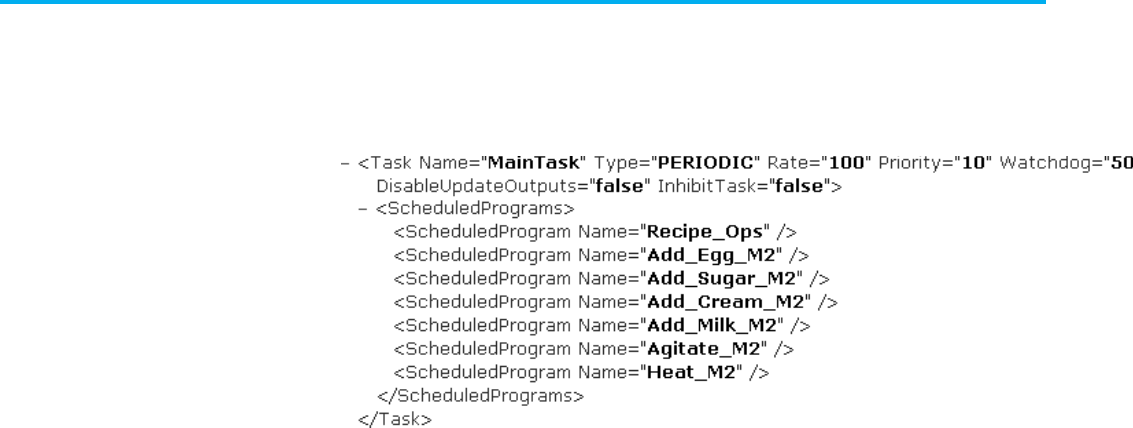

Task component introduction ................................................................ 243

Task component ....................................................................................... 243

L5K TASK structure ............................................................................ 243

L5X task structure .............................................................................. 243

Task elements .....................................................................................244

Task attributes ....................................................................................244

Define a task component

Table of Contents

Publication 1756-RM014B-EN-P - November 2023 15

Task guidelines .........................................................................................244

Task component examples ...................................................................... 245

Chapter 15

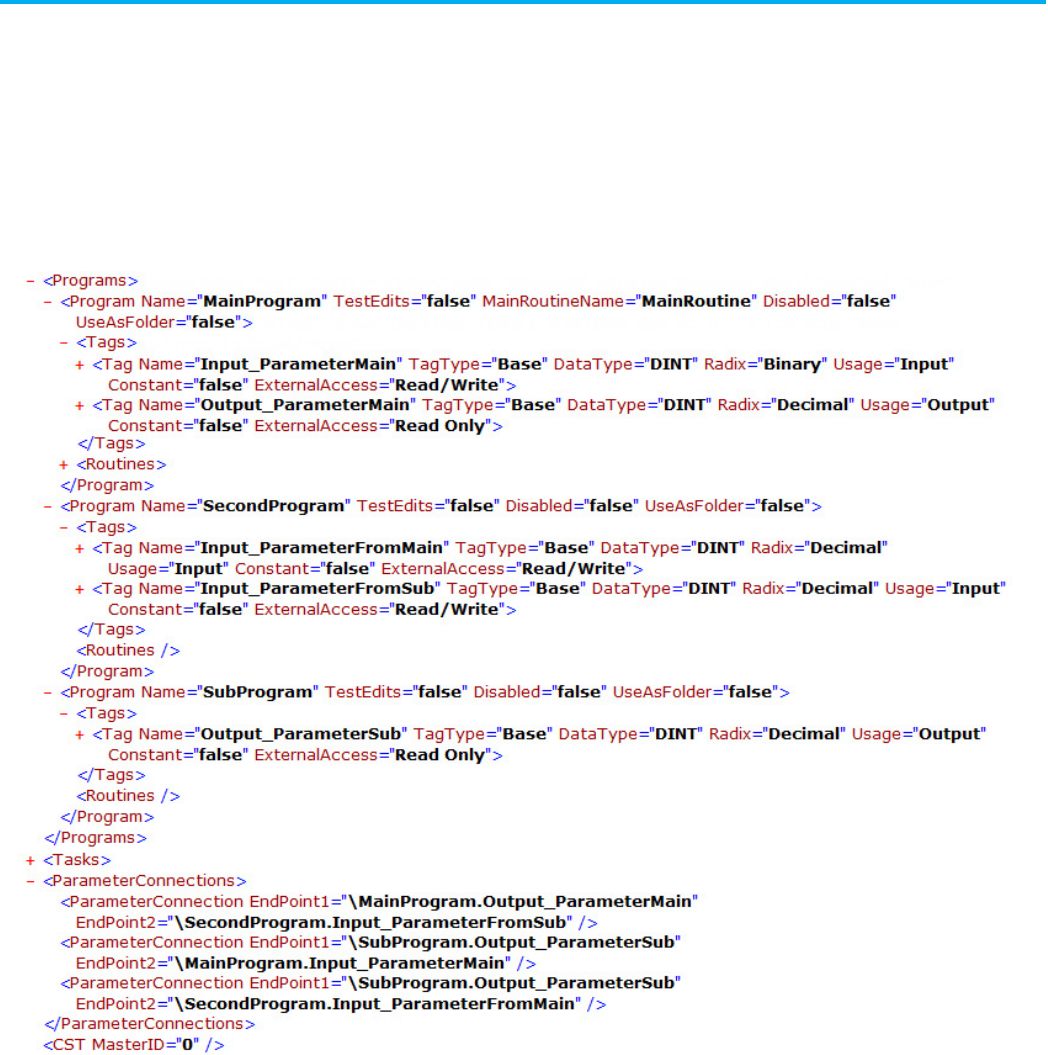

Parameter connection component introduction .................................. 247

Parameter connection component ......................................................... 247

L5K PARAMETER_CONNECTION structure .................................. 247

L5X ParameterConnection structure ............................................... 247

Parameter connection attributes ...................................................... 247

Parameter connection guidelines .......................................................... 248

Parameter connection component examples ....................................... 248

Chapter 16

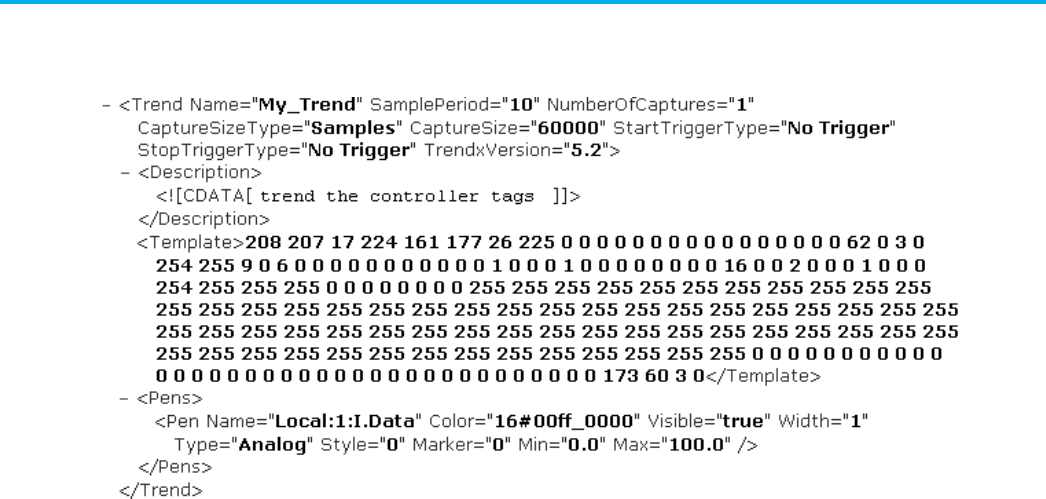

Trend component introduction ...............................................................251

Trend component .....................................................................................251

L5X trend structure ............................................................................ 251

L5K TREND structure ........................................................................ 251

Trend elements ...................................................................................252

Trend attributes .................................................................................252

Pen declaration ......................................................................................... 254

L5X pen structure ............................................................................... 254

L5K PEN structure.............................................................................. 255

Pen elements ...................................................................................... 255

Pen attributes ..................................................................................... 255

Trend guidelines ....................................................................................... 255

Trend component examples .................................................................... 256

Chapter 17

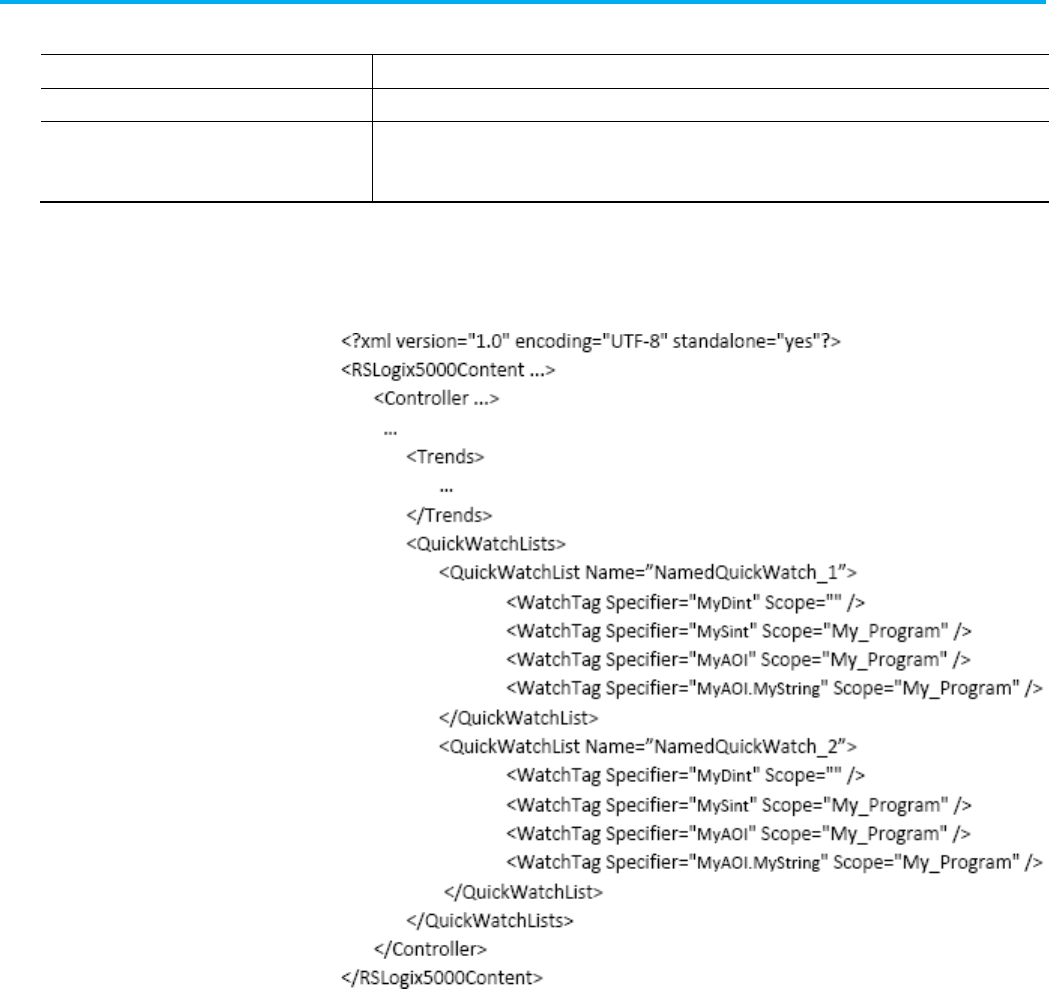

Watch list component introduction ....................................................... 259

Quick watch list component ................................................................... 259

L5X QuickWatchList structure.......................................................... 259

L5K QUICK_WATCH structure ......................................................... 259

Quick Watch elements ....................................................................... 259

Quick Watch List attributes .............................................................. 259

Watch tag attributes ......................................................................... 260

Watch list component examples ............................................................ 260

Chapter 18

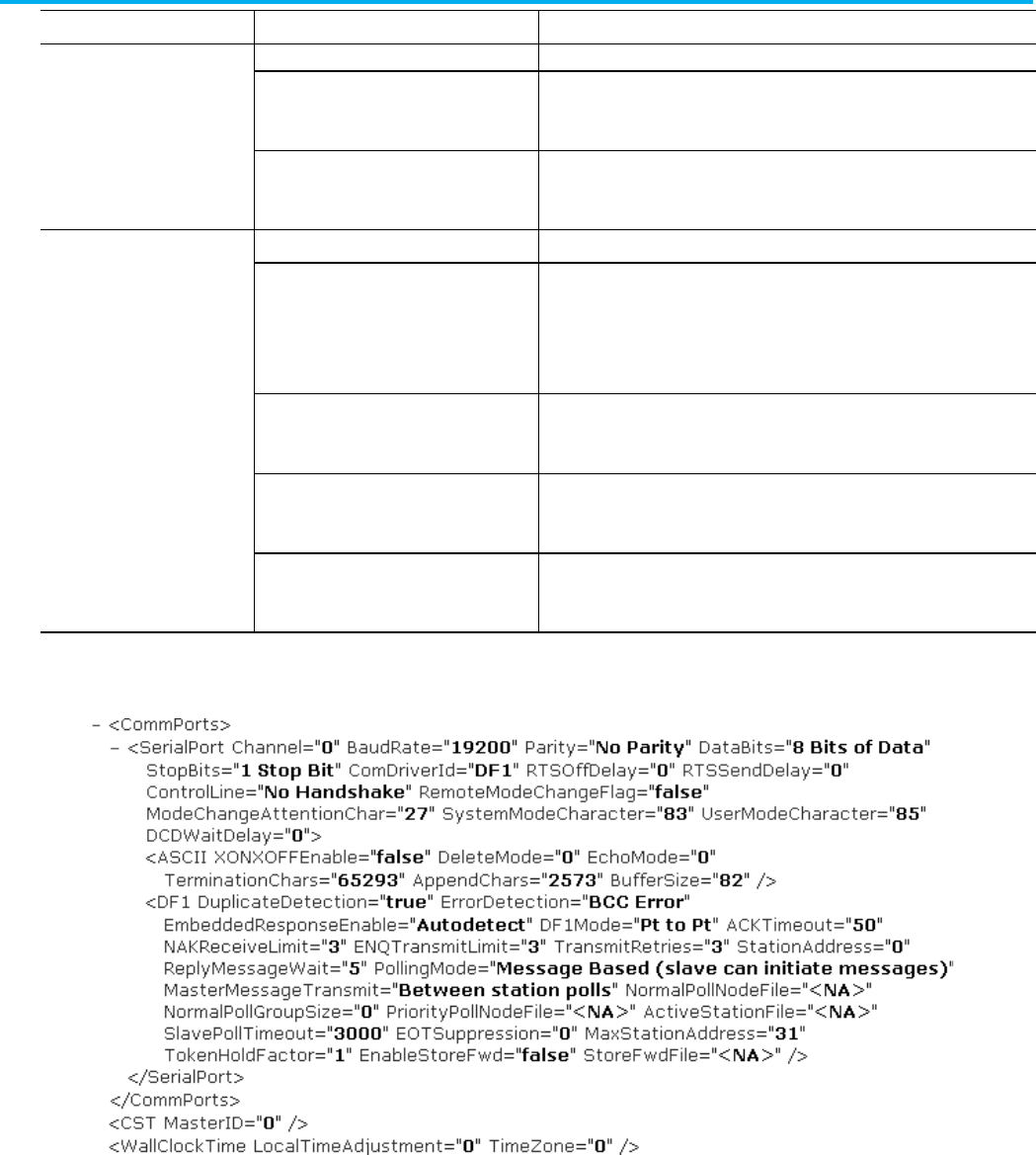

Controller configuration objects introduction ...................................... 263

Controller objects ..................................................................................... 263

L5X config structure .......................................................................... 263

Define a parameter connection

component

Define a trend component

Define a watch list component

Define controller configuration

objects

Table of Contents

16 Publication 1756-RM014B-EN-P - November 2023

L5K CONFIG structure ...................................................................... 263

Object elements .................................................................................. 263

Config attributes ................................................................................264

Controller objects examples ....................................................................266

Chapter 19

Custom properties introduction............................................................. 269

Custom properties data ........................................................................... 269

Custom properties structure .............................................................269

Custom properties elements ............................................................ 270

Custom properties attributes ........................................................... 270

Custom properties example ................................................................... 270

Chapter 20

Safety Signatures introduction ...............................................................271

Safety Signature examples ...................................................................... 272

Signature protection and authentication............................................... 279

Authentication code examples .......................................................... 279

Chapter 21

Structure tags and comments introduction .......................................... 281

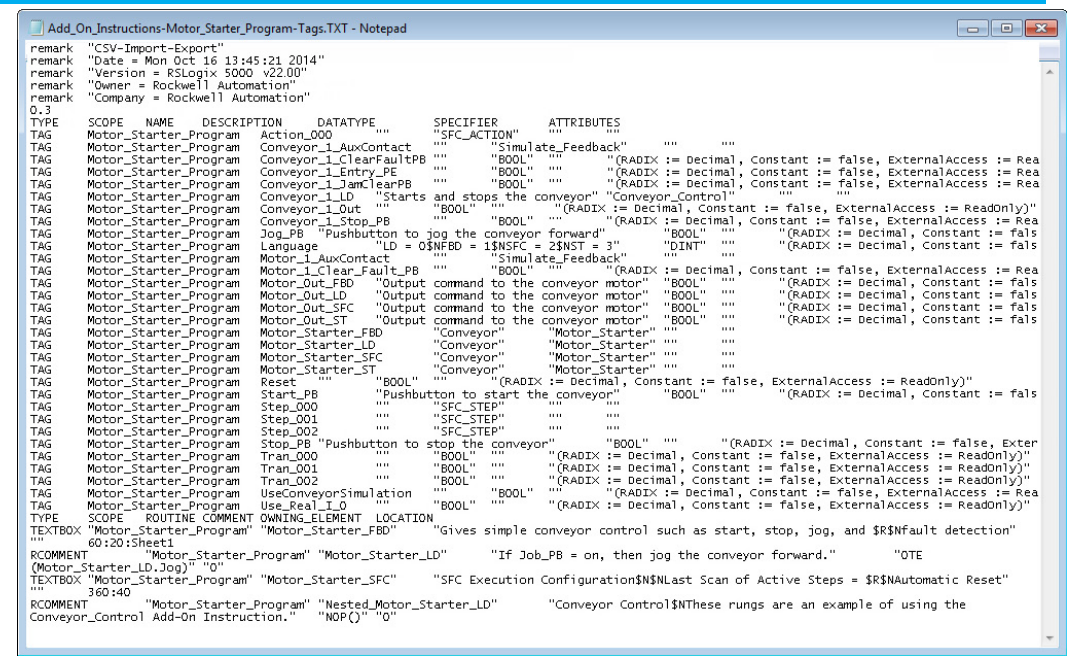

Place information in a .CSV or .TXT file ................................................ 281

L5K Internal file comments ............................................................... 281

Specify a tag record .................................................................................. 281

TAG type record ................................................................................. 282

ALIAS type record.............................................................................. 282

COMMENT type record .....................................................................283

Specify a comment record .......................................................................283

Specify an alarm message record ........................................................... 284

Specify a tag record examples .................................................................285

Appendix A

Microsoft Excel and CSV file introduction ............................................ 291

Recommendations ................................................................................... 291

Logix Designer data transformations .................................................... 291

Microsoft Excel Data Transformation ................................................... 292

Appendix B

Import and export revision history introduction.................................. 293

Backward compatibility........................................................................... 293

Import/Export version 2.27 Logix Designer application version 36 .....294

Define custom properties

Define Safety Signatures

Structure Tags and Comments

in an Import/Export File

Considerations for using

Microsoft Excel to edit a .CSV

file

Import/Export revision history

Table of Contents

Publication 1756-RM014B-EN-P - November 2023 17

Import/Export version 2.22 Logix Designer application version 31 .....294

Import/Export version 2.21 Logix Designer application version 30 .....294

Import/Export version 2.20 Logix Designer application version 29 .... 295

Import/Export version 2.19 Logix Designer application version 28 ..... 295

Import/Export version 2.18 Logix Designer application version 27 ..... 295

Import/Export version 2.17 Logix Designer application version 26 ..... 295

Import/Export version 2.15 Logix Designer application version 24 ..... 295

Import/Export version 2.12 Logix Designer application version 21 .....296

Import/Export version 2.11 Logix Designer version 20 .........................296

Import/Export version 2.10 Logix Designer version 19 ......................... 297

Import/Export version 2.8 Logix Designer version 18........................... 297

Import/Export version 2.8 Logix Designer version 17 ........................... 297

Import/Export version 2.7 Logix Designer version 16 .......................... 298

Import/Export version 2.6 Logix Designer version 15 ...........................299

Import/Export version 2.4 Logix Designer version 13 ...........................299

Import/Export version 2.3 Logix Designer version 12 ...........................299

Import/Export version 2.2 Logix Designer version 11 .......................... 300

Import/Export version 2.1 Logix Designer version 10 ........................... 301

Changes to support MESSAGE tag enhancements ......................... 301

Import/Export version 2.0 Logix Designer version 9 ........................... 302

Motion changes to support the SERCOS Protocol................................ 302

MOTION_GROUP tag structure (version 1.1) .................................. 303

AXIS tag structure (version 1.1) ......................................................... 303

Import/Export version 1.1 Logix Designer version 8 ............................ 306

Index

Publication 1756-RM014B-EN-P - November 2023 19

Preface

This manual details how to import and export controller projects. You should

be familiar with how the Logix-based controller stores and processes data.

This manual is one of a set of related manuals that show common procedures

for programming and operating Logix 5000 controllers.

For a complete list of common procedures manuals, refer to the Logix 5000

Controllers Common Procedures Programming Manual, publication

1756-PM001.

The term Logix 5000 controller refers to any controller based on the Logix

5000 operating system.

Rockwell Automation recognizes that some of the terms that are currently

used in our industry and in this publication are not in alignment with the

movement toward inclusive language in technology. We are proactively

collaborating with industry peers to find alternatives to such terms and

making changes to our products and content. Please excuse the use of such

terms in our content while we implement these changes.

The Studio 5000 Automation Engineering & Design Environment® combines

engineering and design elements into a common environment. The first

element is the Studio 5000 Logix Designer® application. The Logix Designer

application is the rebranding of RSLogix 5000® software and will continue to

be the product to program Logix 5000™ controllers for discrete, process,

batch, motion, safety, and drive-based solutions.

The Studio 5000® environment is the foundation for the future of

Rockwell Automation® engineering design tools and capabilities. The Studio

5000 environment is the one place for design engineers to develop all

elements of their control system.

Studio 5000 environment

Preface

20 Publication 1756-RM014B-EN-P - November 2023

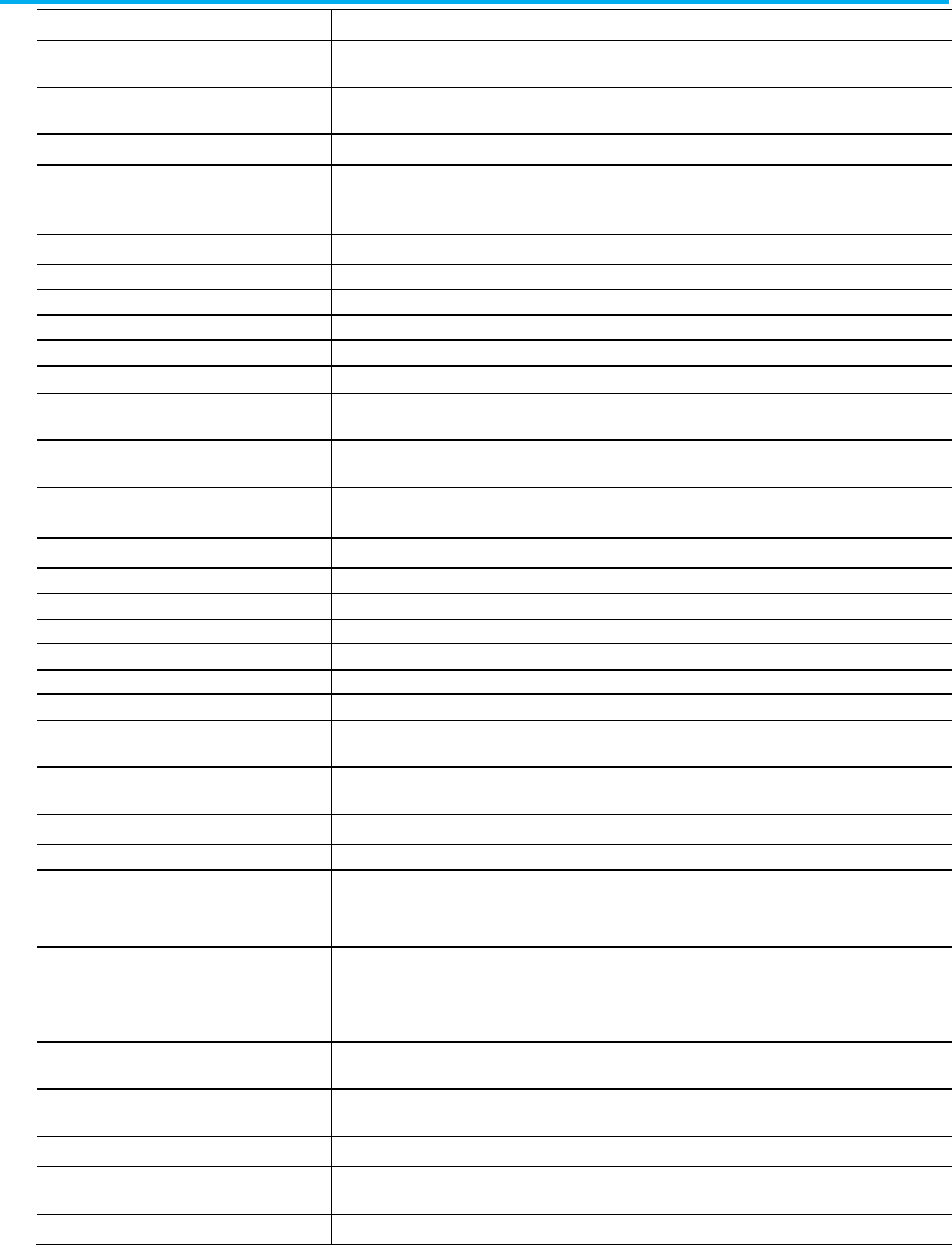

The supported controllers list includes:

• 1756-L71

• 1756-L71S

• 1756-L72

• 1756-L72S

• 1756-L73

• 1756-L73S

• 1756-L74

• 1756-L75

• 1756-L81E

• 1756-L81ES

• 1756-L81S

• 1756-L82E

• 1756-L82ES

• 1756-L82S

• 1756-L83E

• 1756-L83ES

• 1756-L83S

• 1756-L84E

• 1756-L84ES

• 1756-L84S

• 1756-L85E

• 1756-L85ES

• 1756-L85S

• 1769-L16ER-BB1B

• 1769-L18ER-BB1B

• 1769-L18ERM-BB1B

• 1769-L19ERM-BB1B

• 1769-L24ER-QB1B

• 1769-L24ER-QBFC1B

• 1769-L27ERM-QBFC1B

• 1769-L30ER

• 1769-L30ERM

• 1769-L30ERMS

• 1769-L30ER-NSE

• 1769-L33ER

• 1769-L33ERM

• 1769-L33ERMS

• 1769-L36ERM

• 1769-L36ERMS

• 1769-L37ERMO

• 1769-L37ERM

• 1769-L37ERMS

• 1769-L38ERM

Supported controllers

Preface

Publication 1756-RM014B-EN-P - November 2023 21

• 1769-L38ERMS

• 1769-L37ERMOS

• 5069-L306ER

• 5069-L306ERM

• 5069-L306ERMS2

• 5069-L306ERMS3

• 5069-L306ERS2

• 5069-L310ER

• 5069-L310ERM

• 5069-L310ERMS2

• 5069-L310ERMS3

• 5069-L310ERS2

• 5069-L310ER-NSE

• 5069-L320ER

• 5069-L320ERM

• 5069-L320ERMS2

• 5069-L320ERMS3

• 5069-L320ERS2

• 5069-L330ER

• 5069-L330ERM

• 5069-L330ERMS2

• 5069-L330ERMS3

• 5069-L330ERS2

• 5069-L340ER

• 5069-L340ERM

• 5069-L340ERMS2

• 5069-L340ERMS3

• 5069-L340ERS2

• 5069-L350ERM

• 5069-L350ERMS2

• 5069-L350ERMS3

• 5069-L350ERS2

• 5069-L380ERM

• 5069-L380ERMS2

• 5069-L380ERMS3

• 5069-L380ERS2

• 5069-L3100ERM

• 5069-L3100ERMS2

• 5069-L3100ERMS3

• 5069-L3100ERS2

• 5069-L46ERMW

• Emulate 5570

Preface

22 Publication 1756-RM014B-EN-P - November 2023

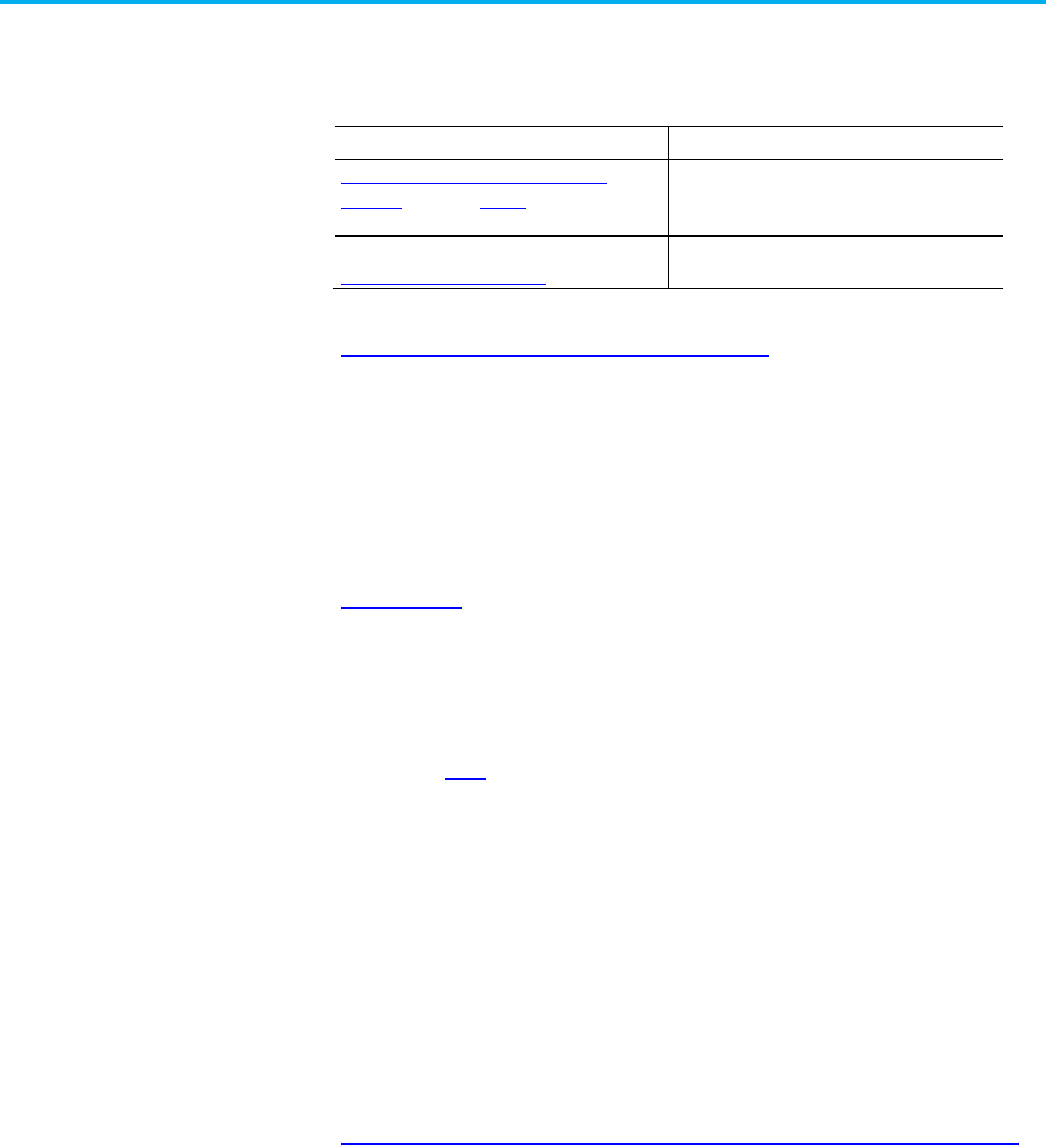

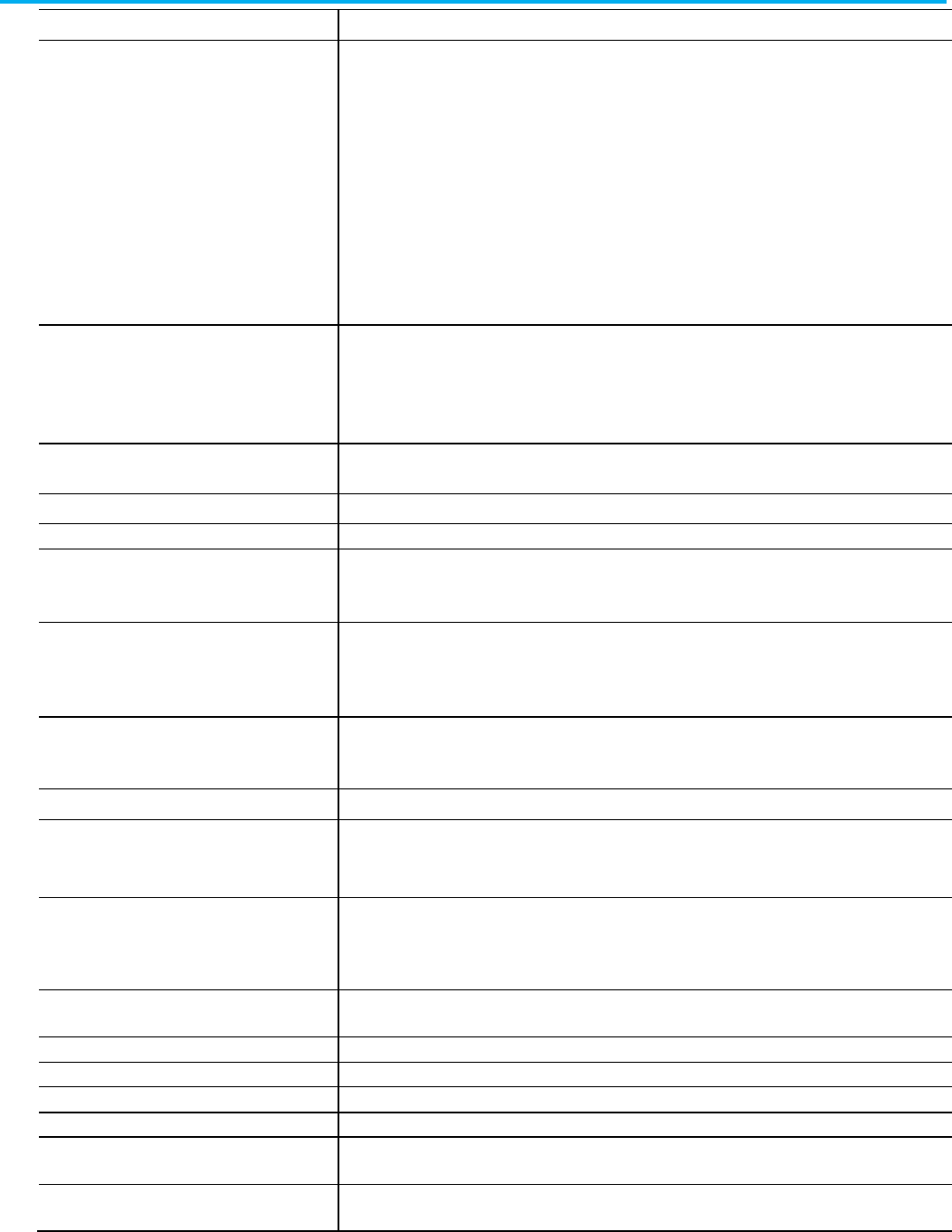

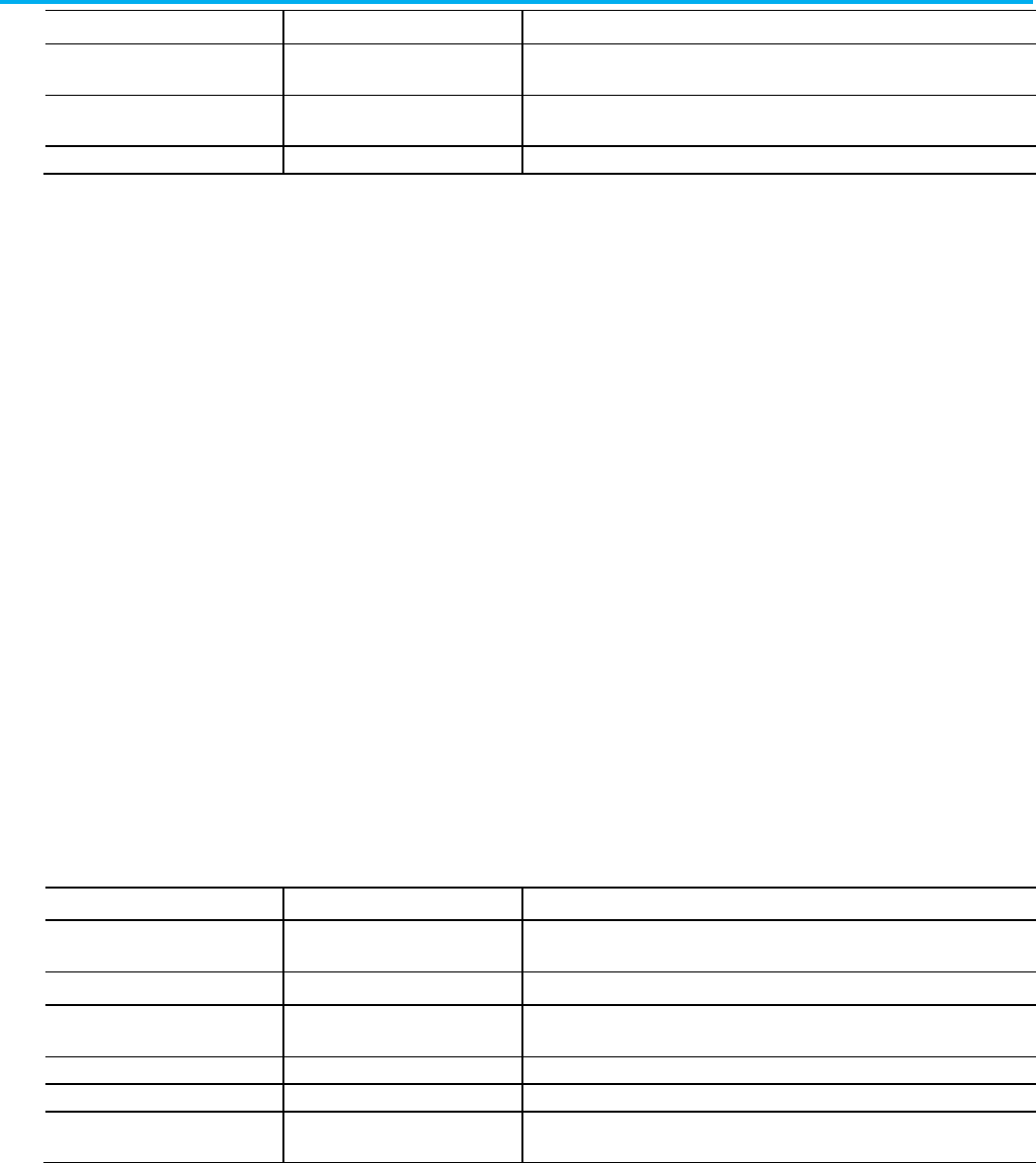

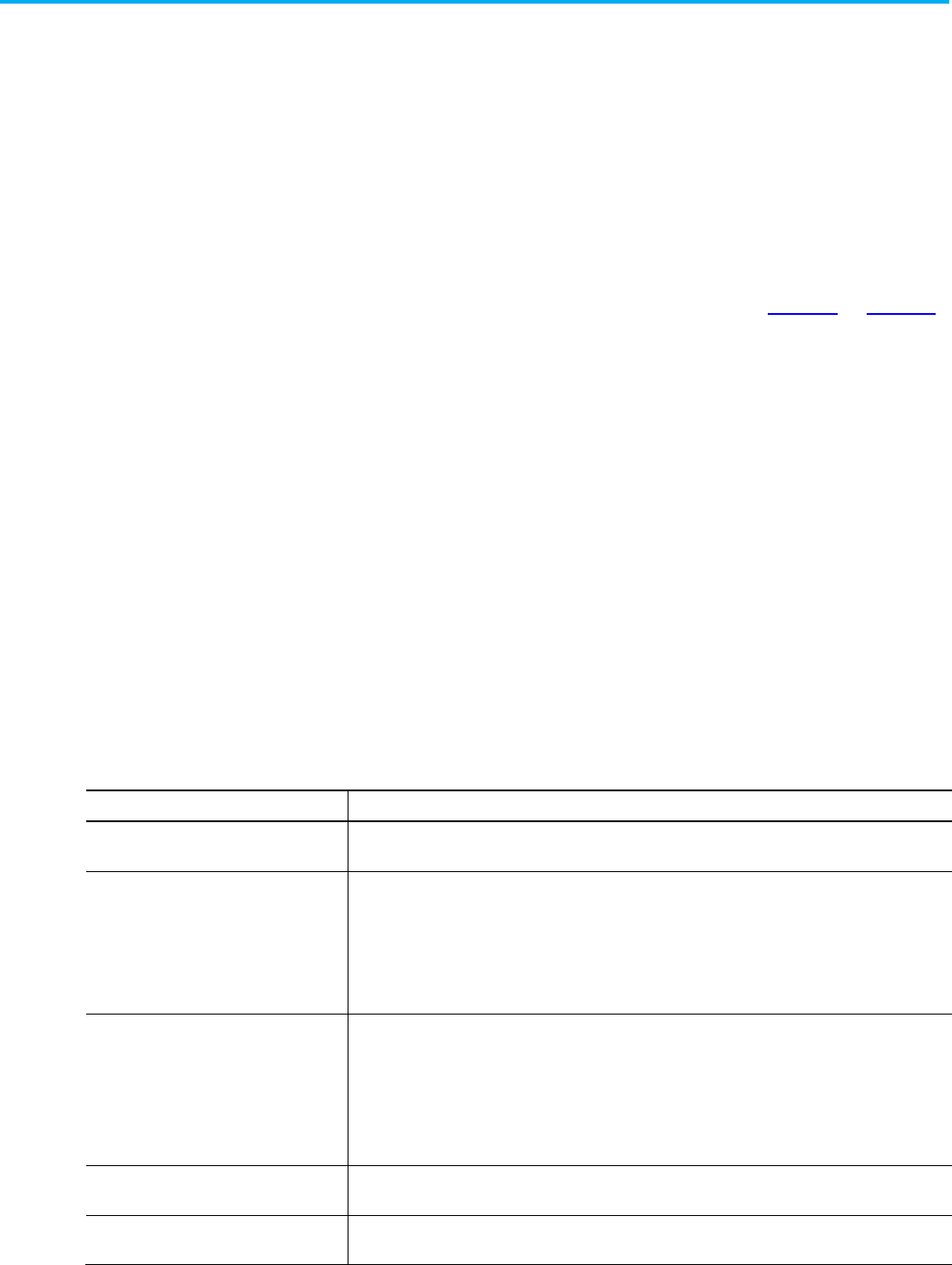

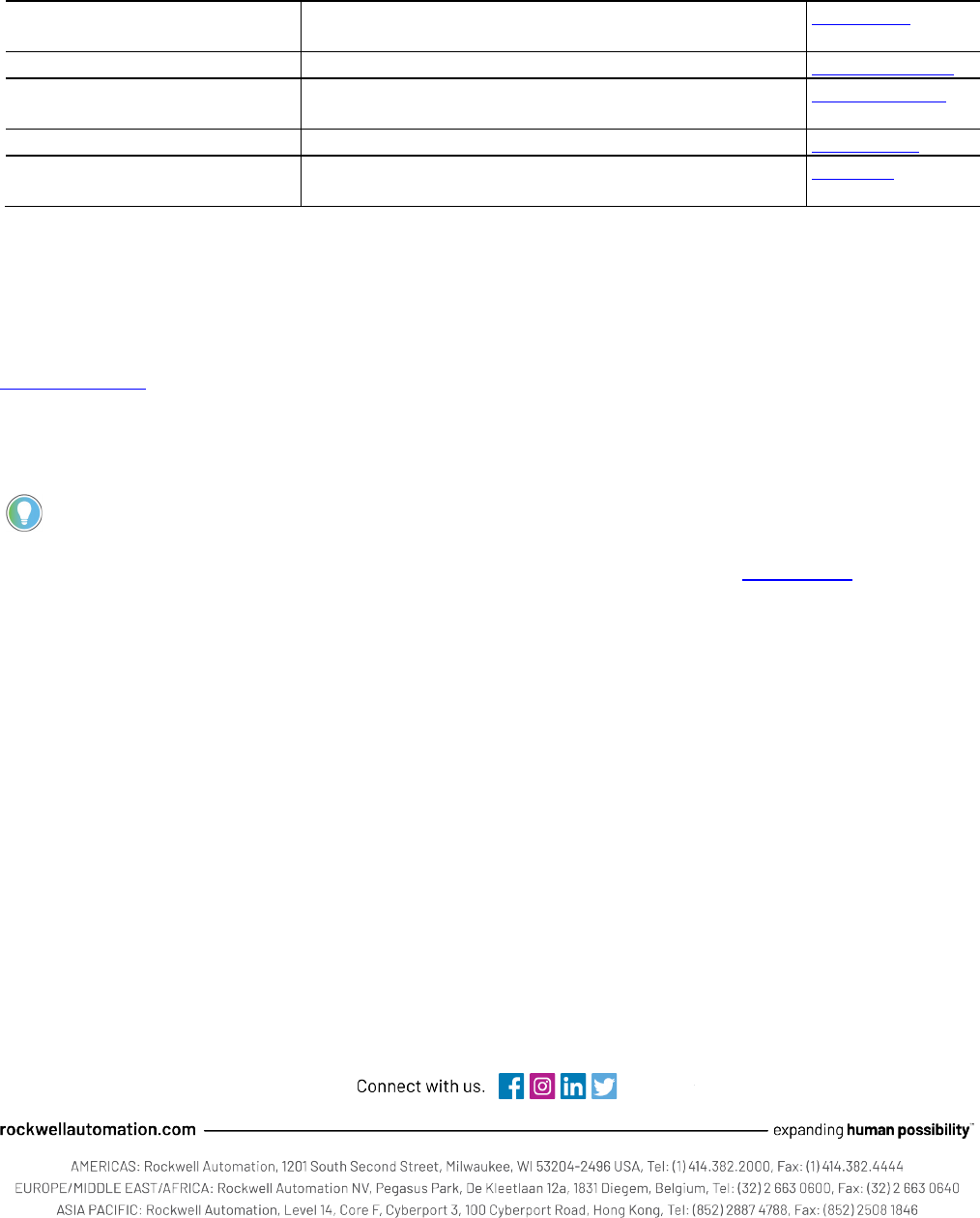

These documents contain additional information concerning related

Rockwell Automation products.

Resource

Description

Industrial Automation Wiring and Grounding

Guidelines, publication 1770-4.1

Provides general guidelines for installing a Rockwell

Automation industrial system.

Product Certifications webpage, available at

http://ab.rockwellautomation.com

Provides declarations of conformity, certificates, and

other certification details.

View or download publications at

http://www.rockwellautomation.com/literature. To order paper copies of

technical documentation, contact the local Rockwell Automation distributor

or sales representative.

Rockwell Automation publishes legal notices, such as privacy policies, license

agreements, trademark disclosures, and other terms and conditions on the

Legal Notices page of the Rockwell Automation website.

Software and Cloud Services Agreement

Review and accept the Rockwell Automation Software and Cloud Services

Agreement here.

Open Source Licenses

The software included in this product contains copyrighted software that is

licensed under one or more open source licenses. Copies of those licenses are

included with the software. Corresponding Source code for open source

packages included in this product are located at their respective web site(s).

Alternately, obtain complete Corresponding Source code by contacting

Rockwell Automation via the Contact form on the Rockwell Automation

website:

http://www.rockwellautomation.com/global/about-us/contact/contact.page

Please include "Open Source" as part of the request text.

A full list of all open source software used in this product and their

corresponding licenses can be found in the OPENSOURCE folder. The default

installed location of these licenses is

C:\Program Files (x86)\Common

Files\Rockwell\Help\<Product Name>\Release

Notes\OPENSOURCE\index.htm

.

Additional resources

Legal Notices

Publication 1756-RM014B-EN-P - November 2023 23

Chapter 1

Import and export files

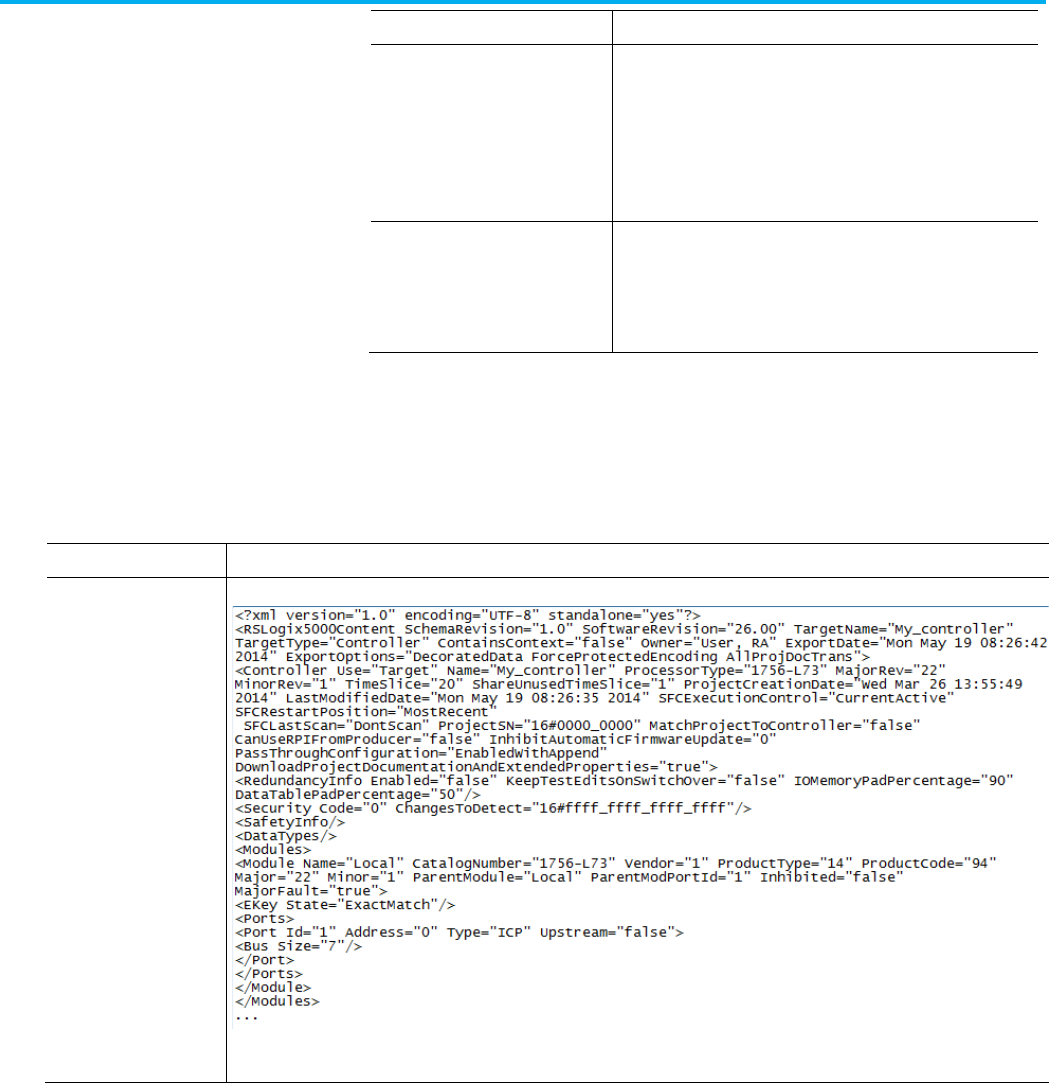

This document describes how to use the import/export feature that is

included with the Logix Designer application.

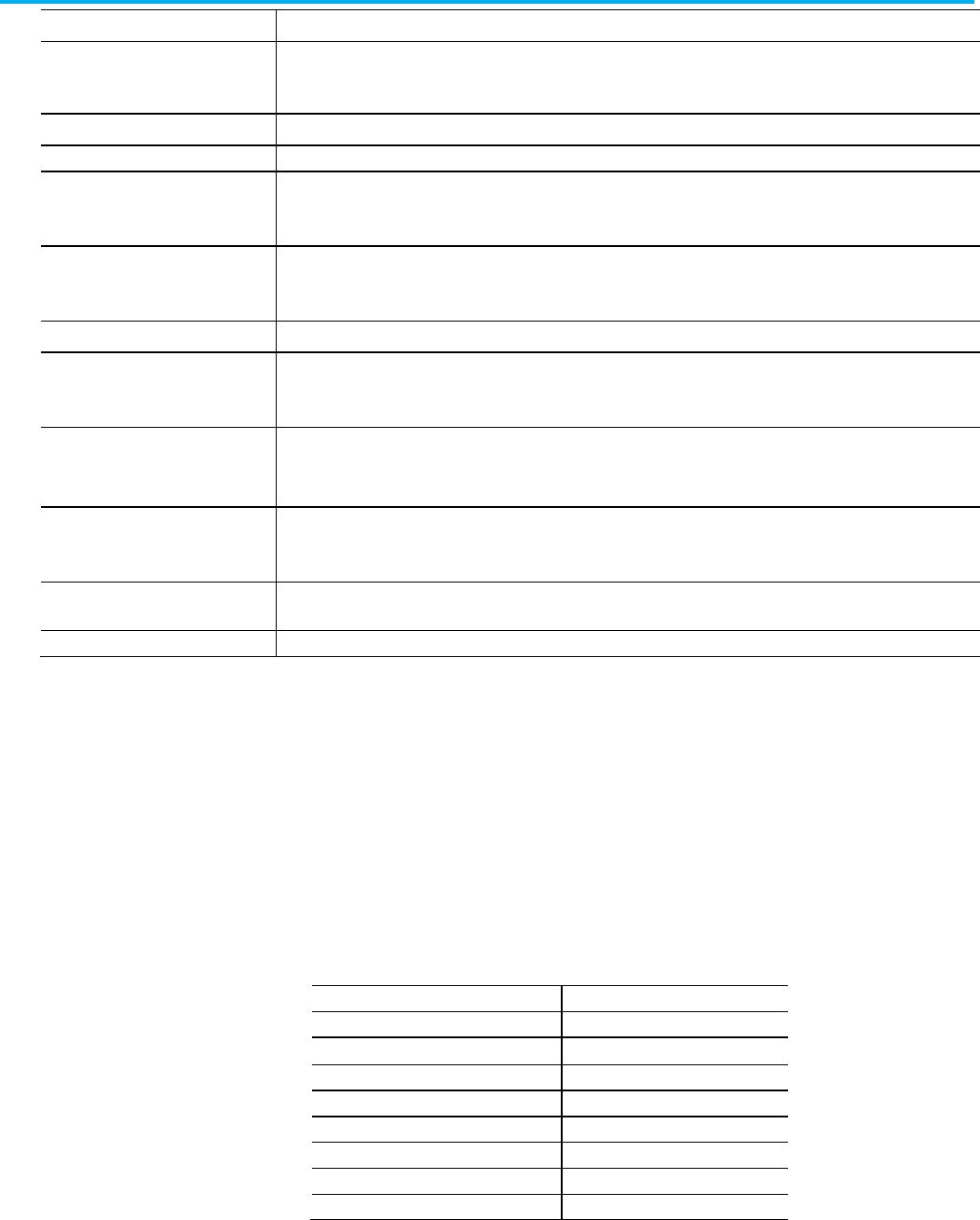

With a Logix controller, you can import and export an entire project or

import and export parts of a project. Select the import/export format based on

what you want from the content.

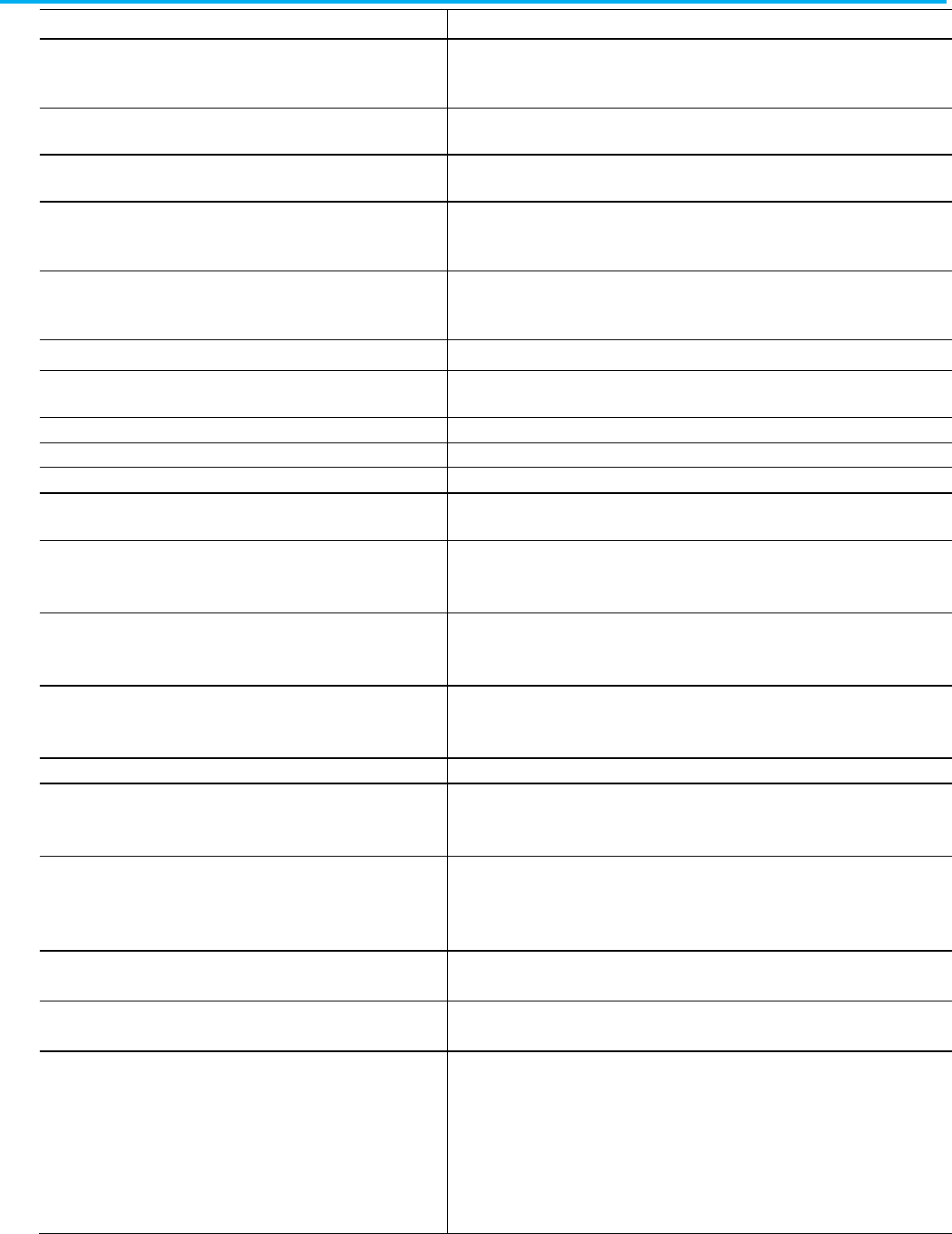

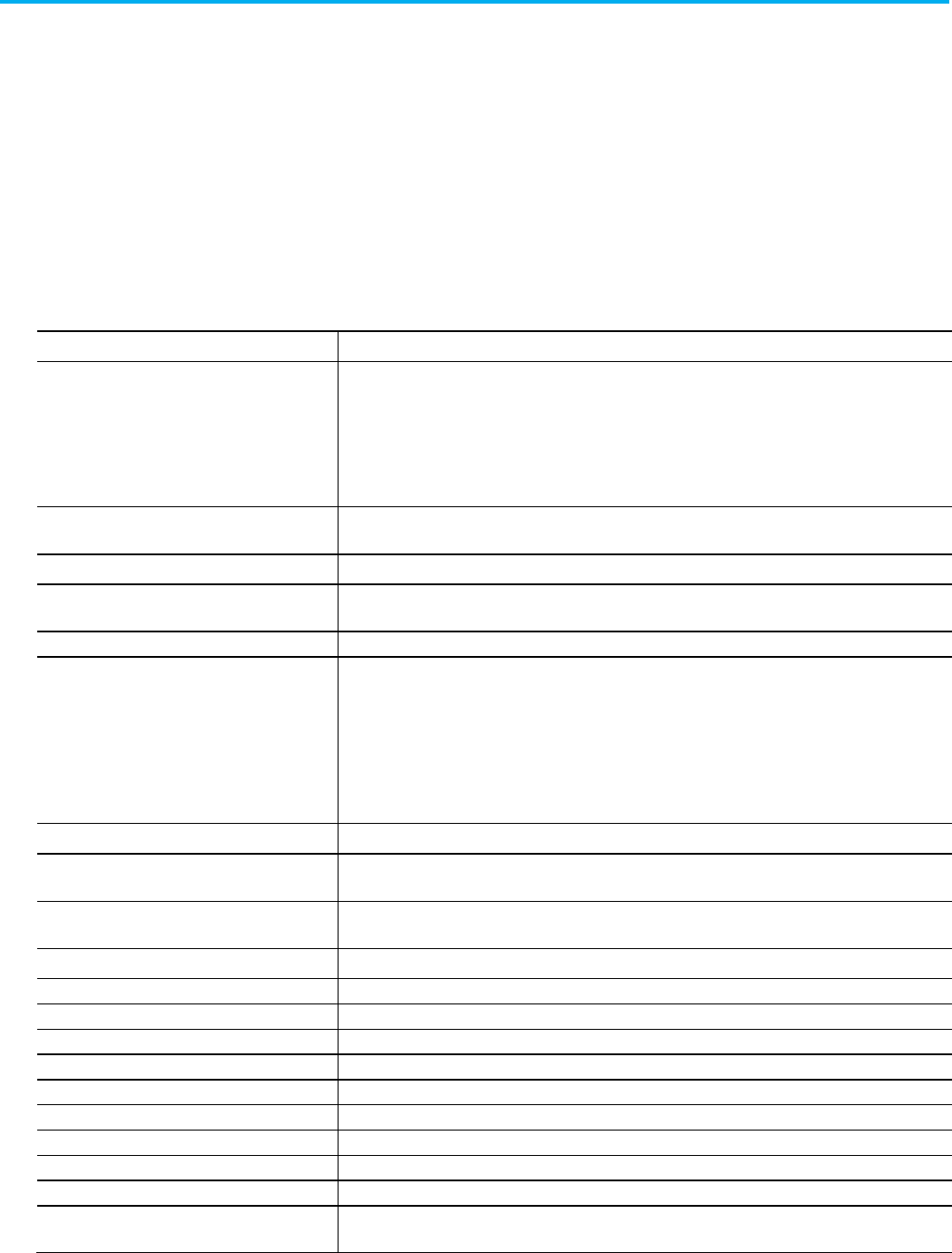

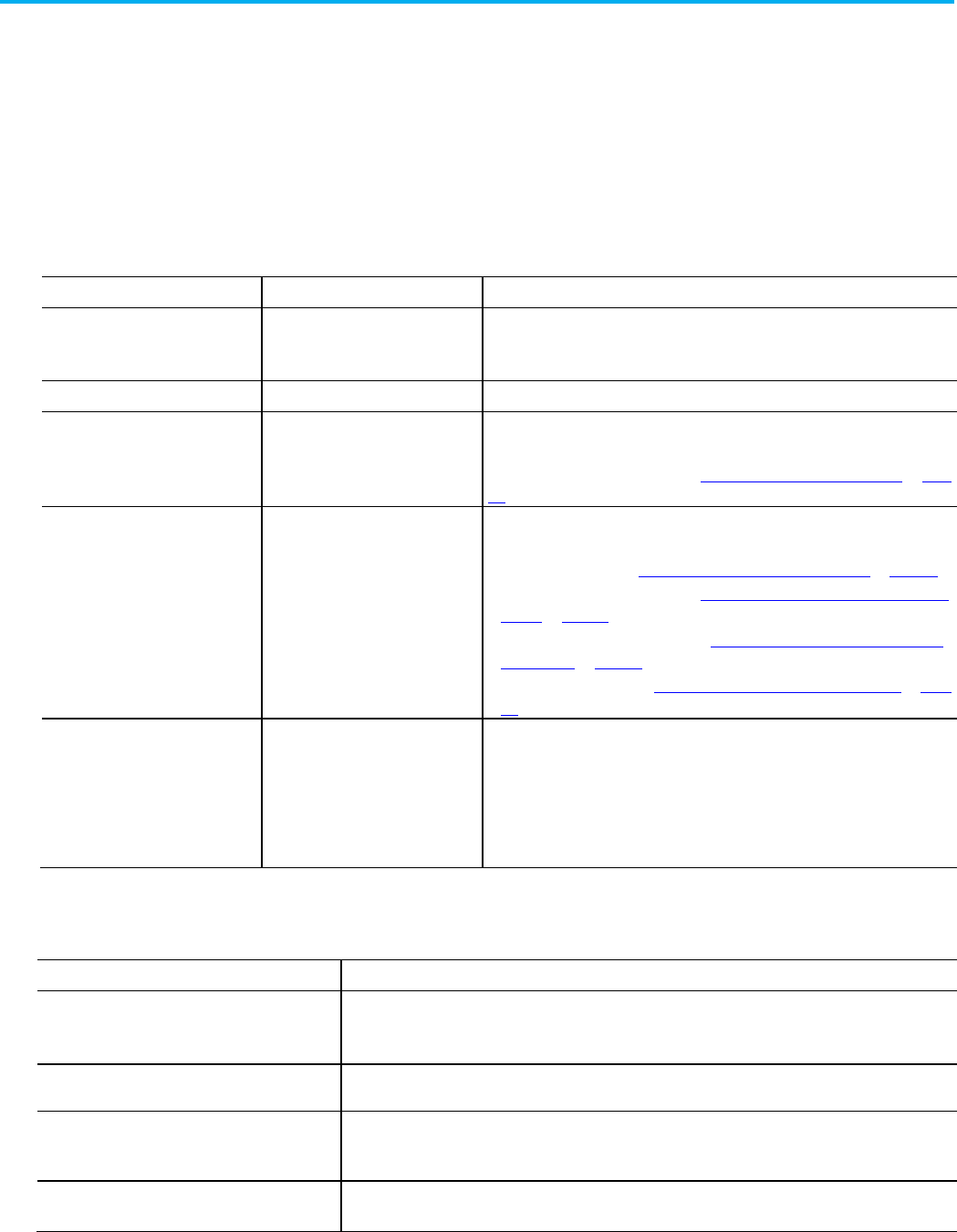

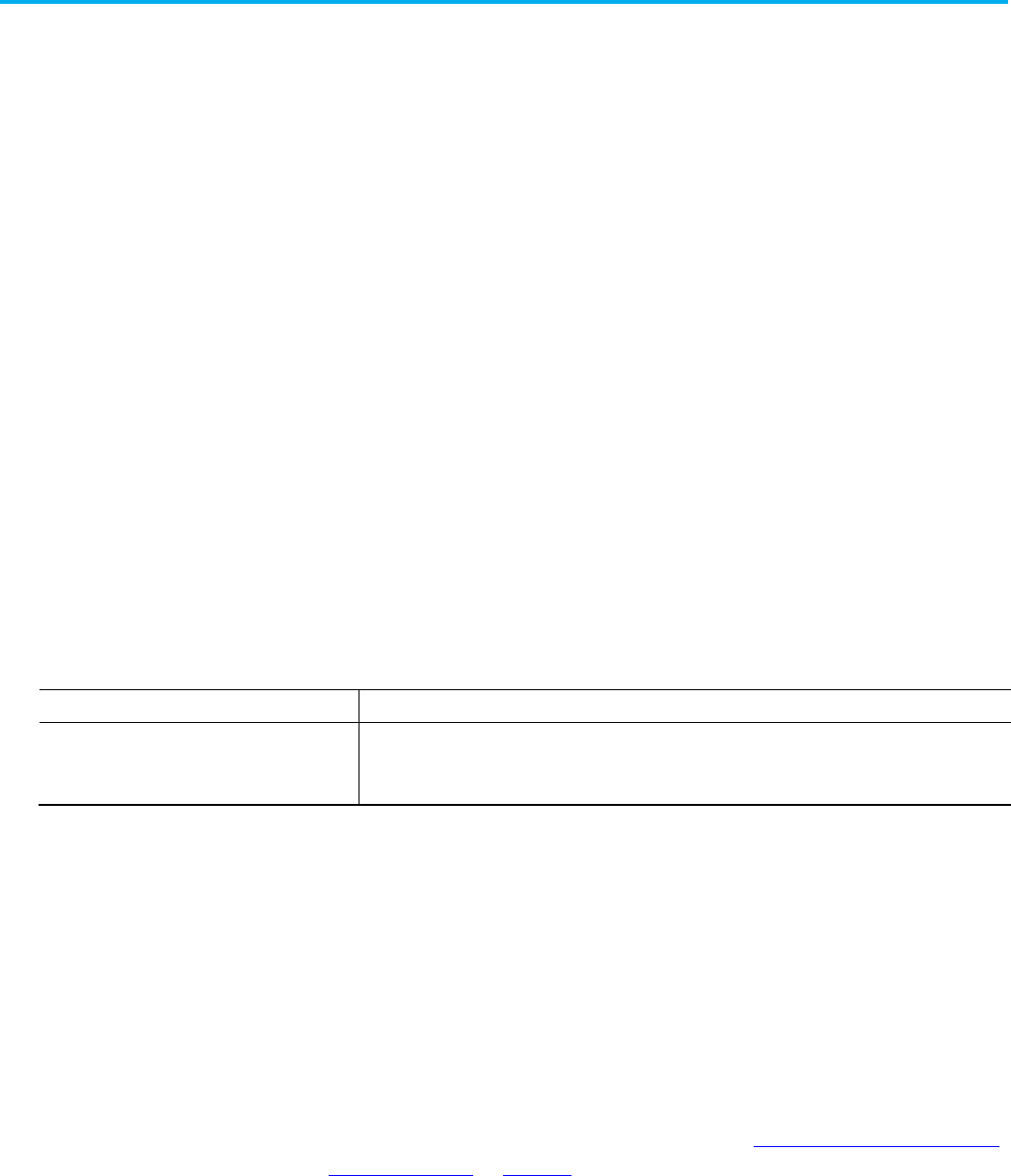

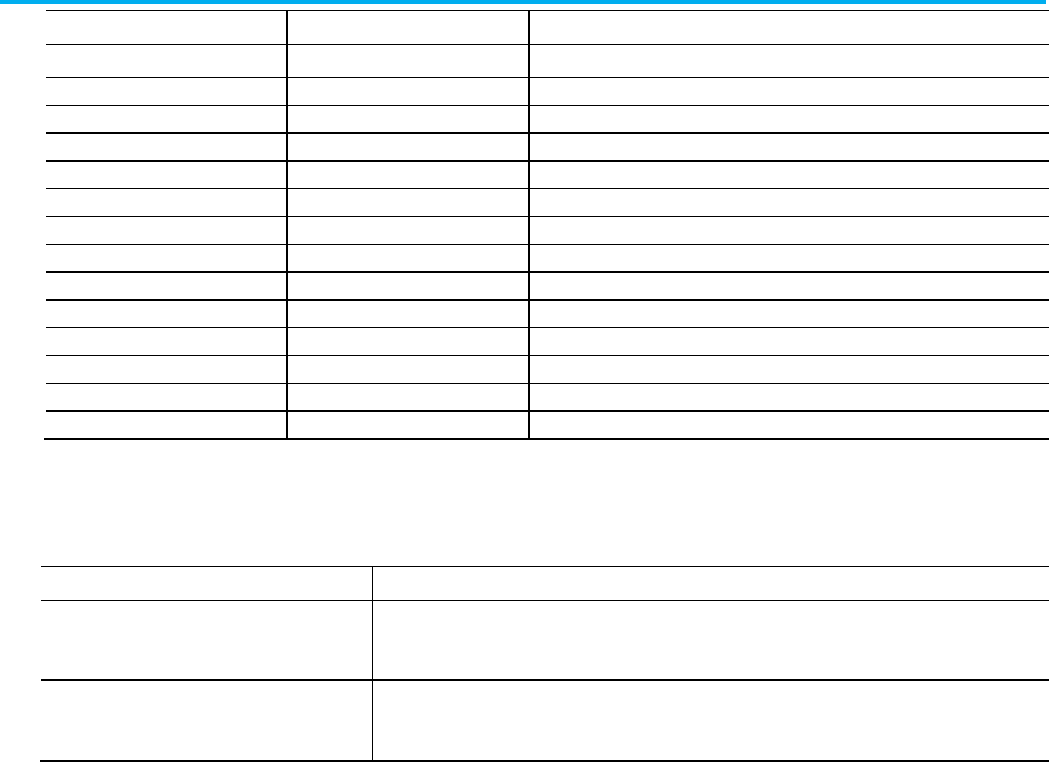

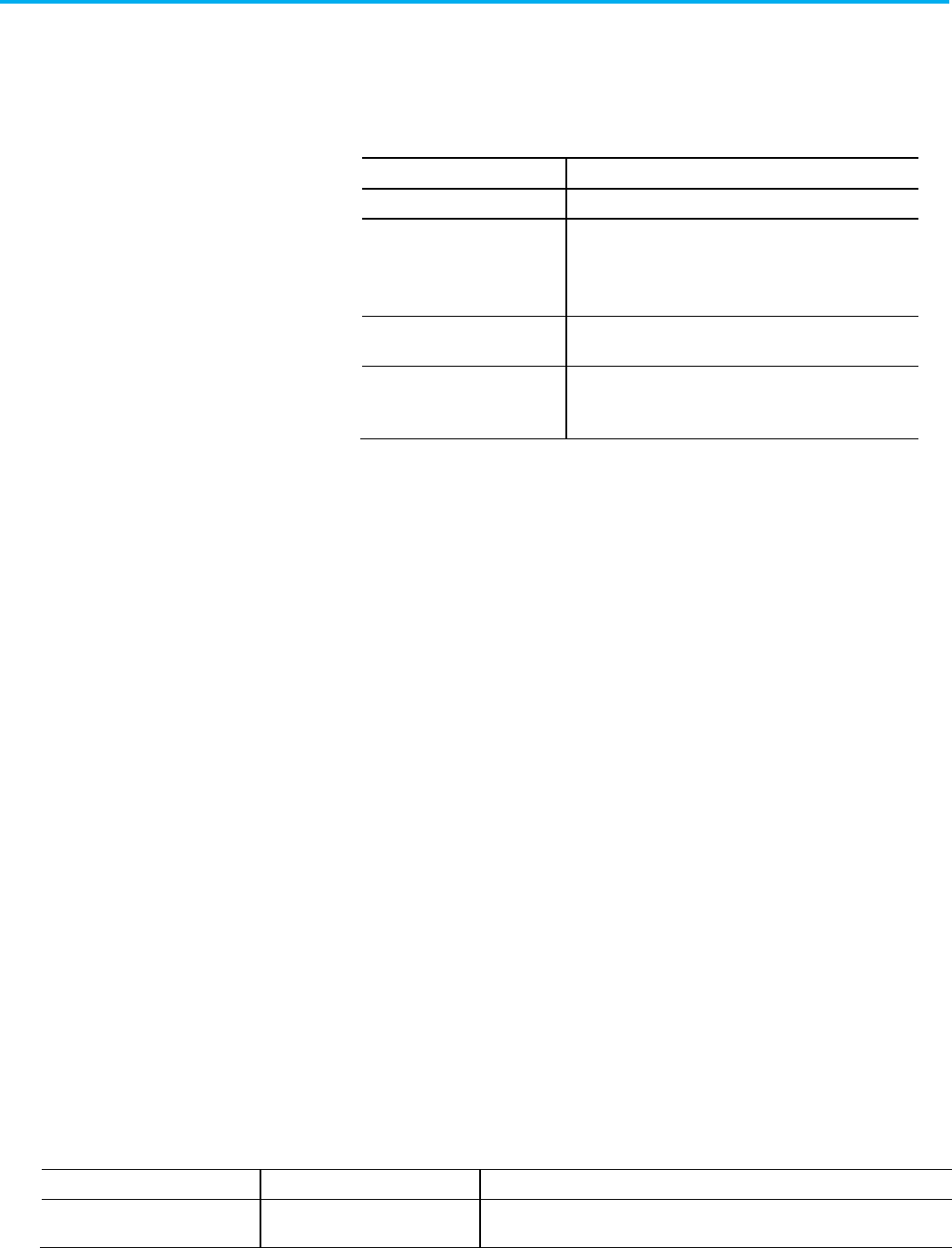

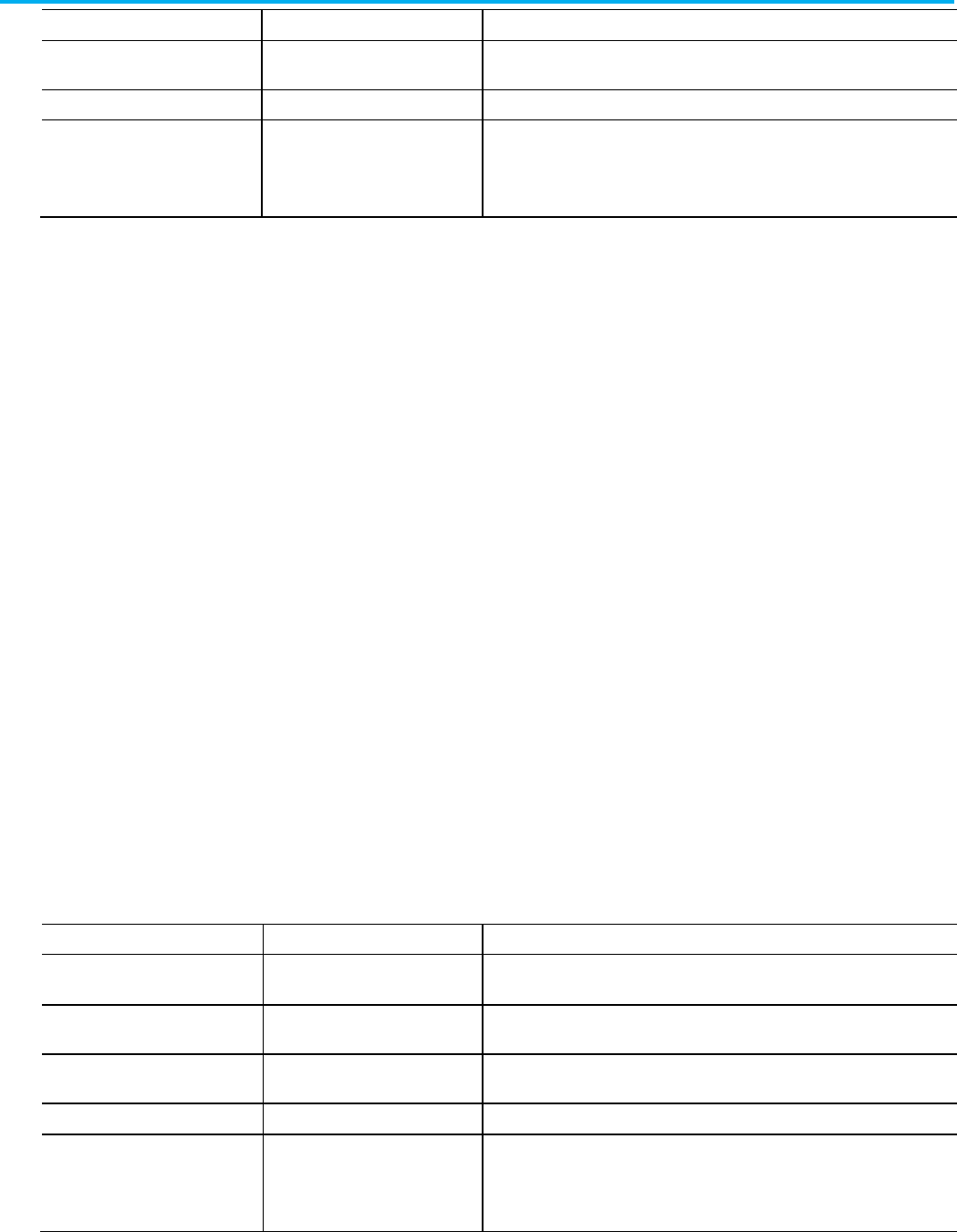

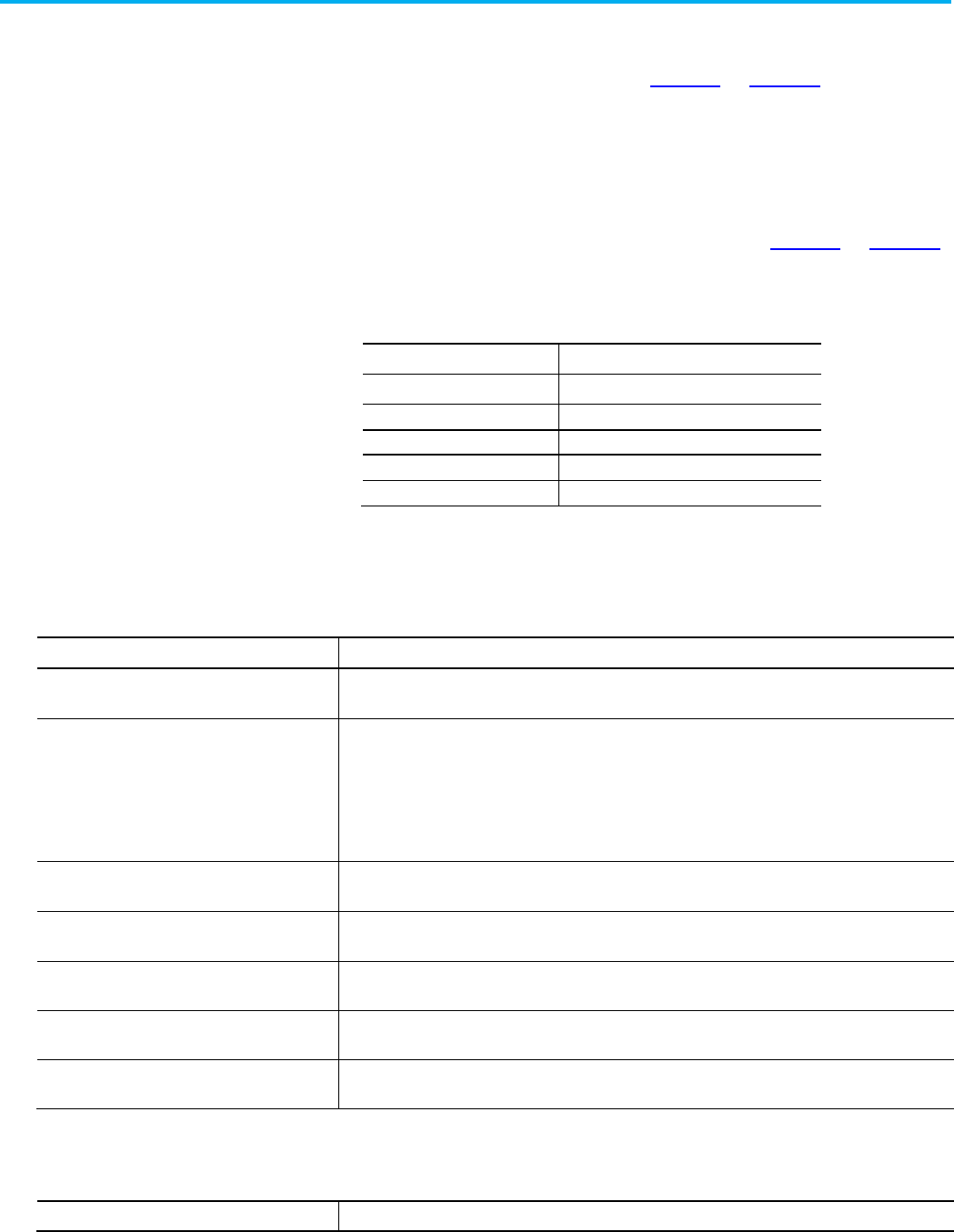

If you want:

Then use this format:

The entire controller project

L5K or L5X

Individual portions of the controller project

L5X

Tags and logic comments

CSV or TXT

This chapter shows how to perform the import/export operations.

You can export a project to a text file and use any text editor that supports

UTF8 file format to modify the project. The exported file will be an .L5K

format.

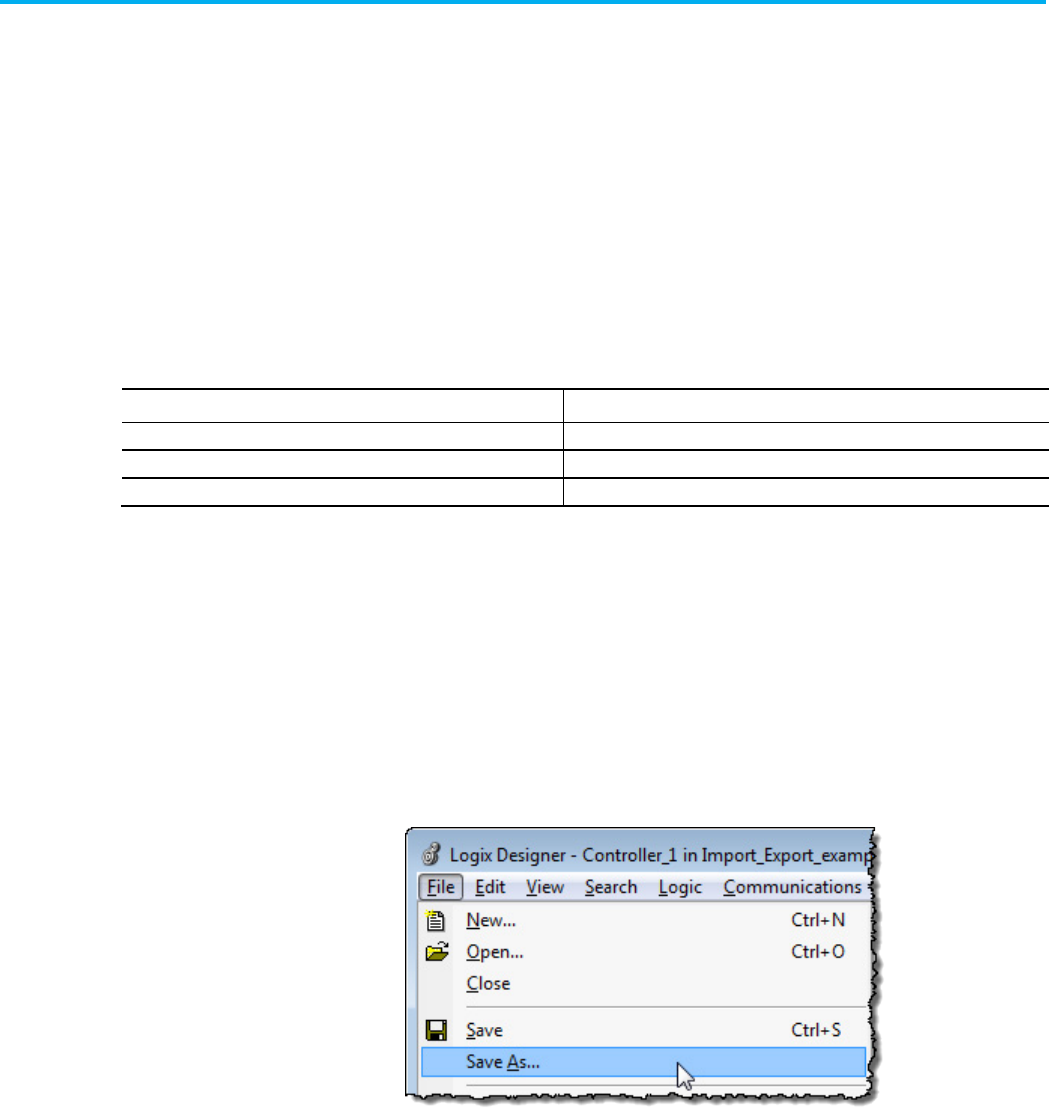

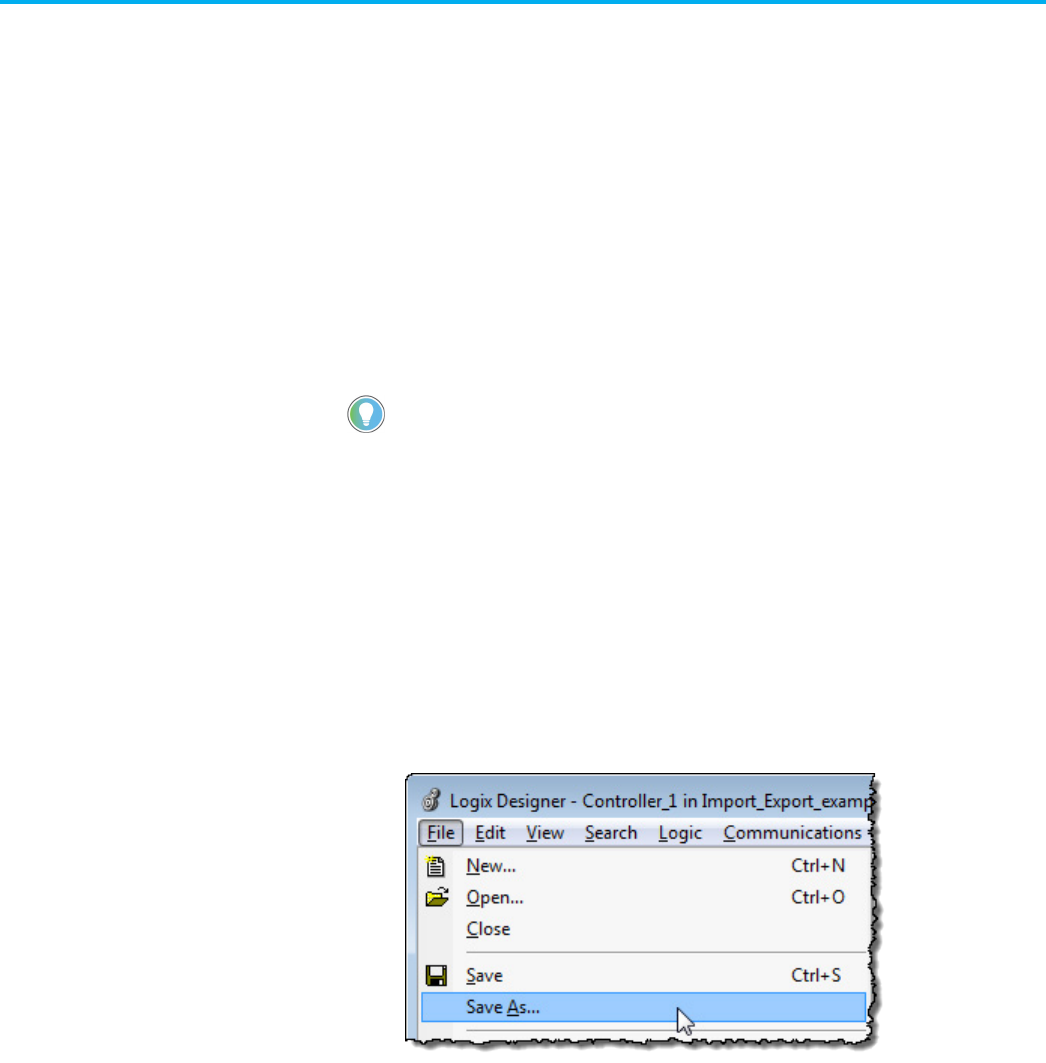

To export a project to an .L5K text file

1. Make sure the project you want to export is open.

2. In the Logix Designer application, select File > Save As.

Import and export

introduction

Export a project to an .L5K

text file

Chapter 1 Import and export files

24 Publication 1756-RM014B-EN-P - November 2023

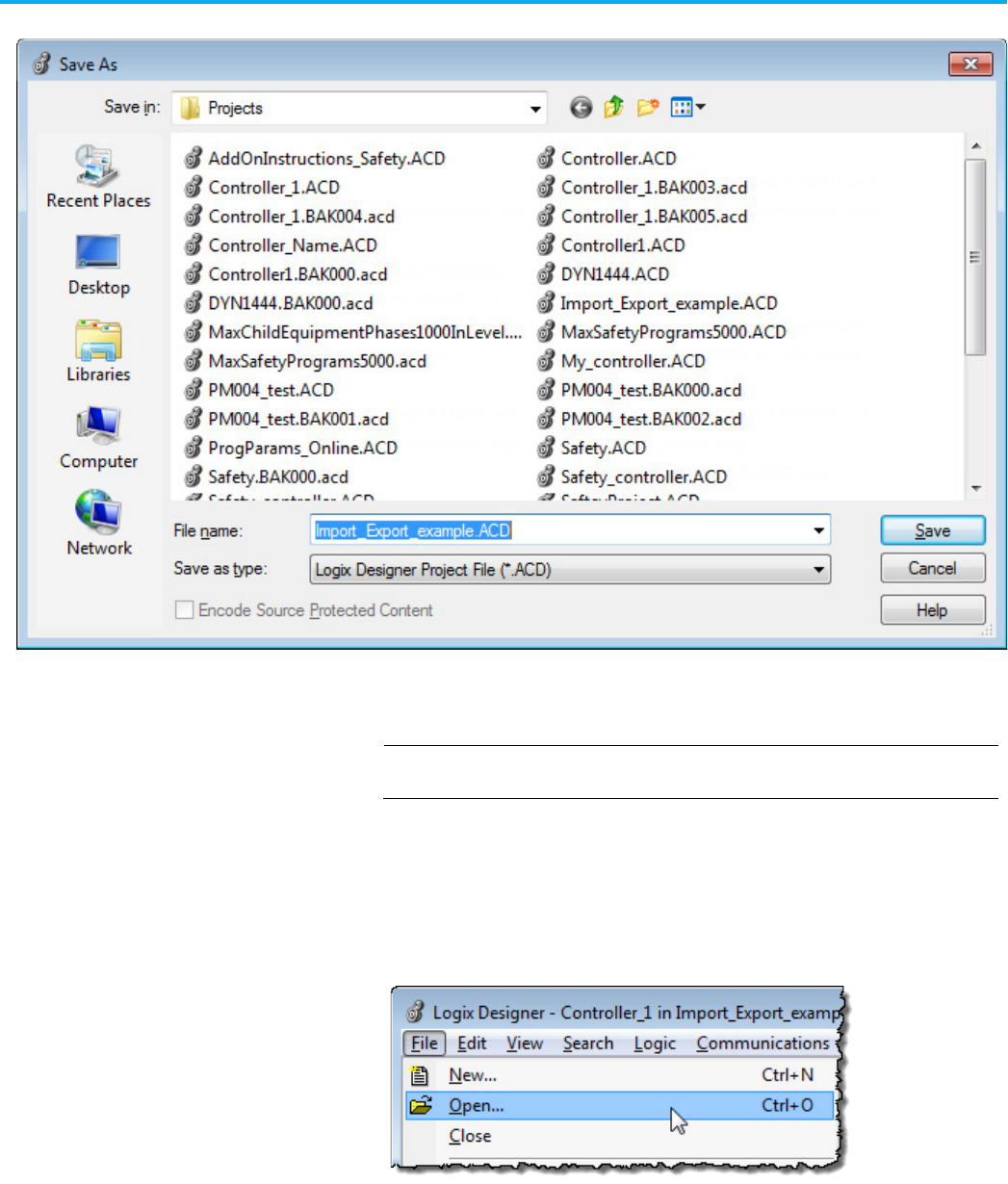

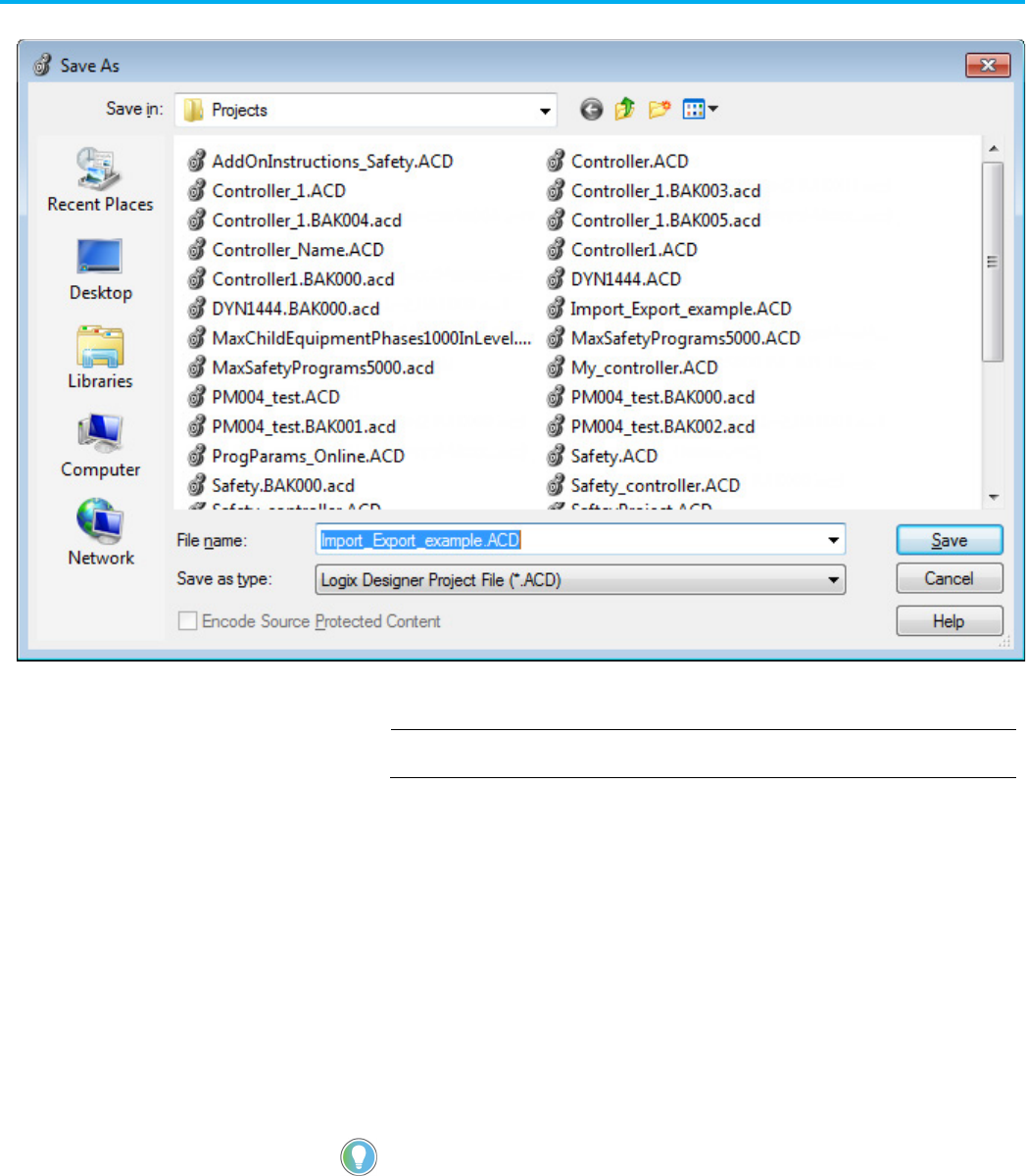

The Save As dialog box opens.

3. Browse to where you want to save the file.

4. In the File name field, type the name of the text file.

5. From the Save as type list, select the .L5K file format and select Save.

IMPORTANT

The application automatically saves any unsaved edits when you select OK.

Import controller information from a saved text file that has an .L5K

extension. This lets you use any text editor to create a project.

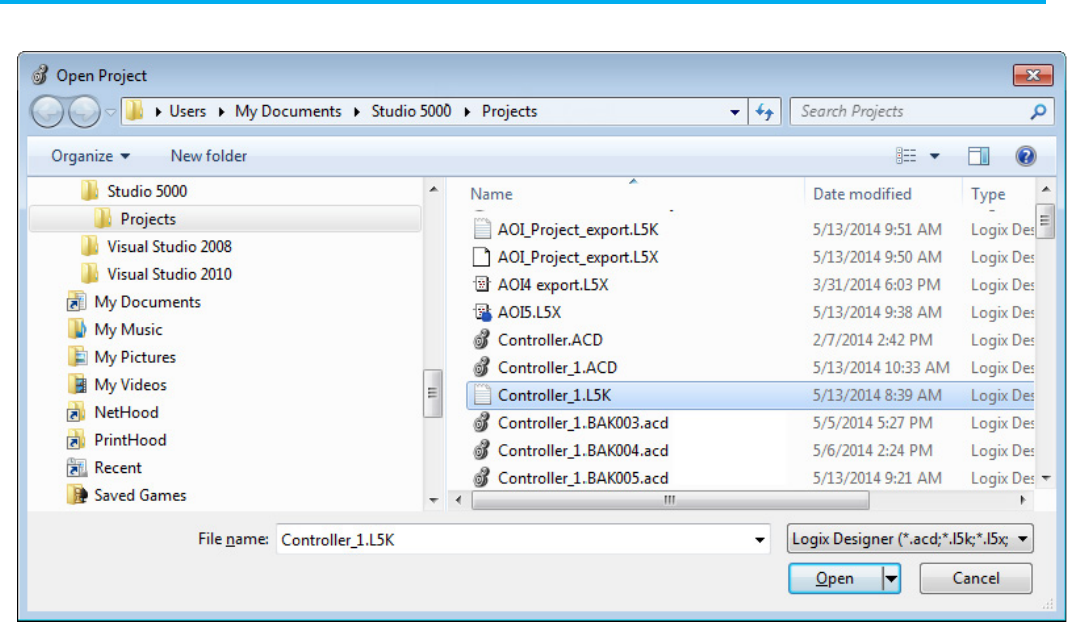

Do these steps to import an .L5K text file into a project.

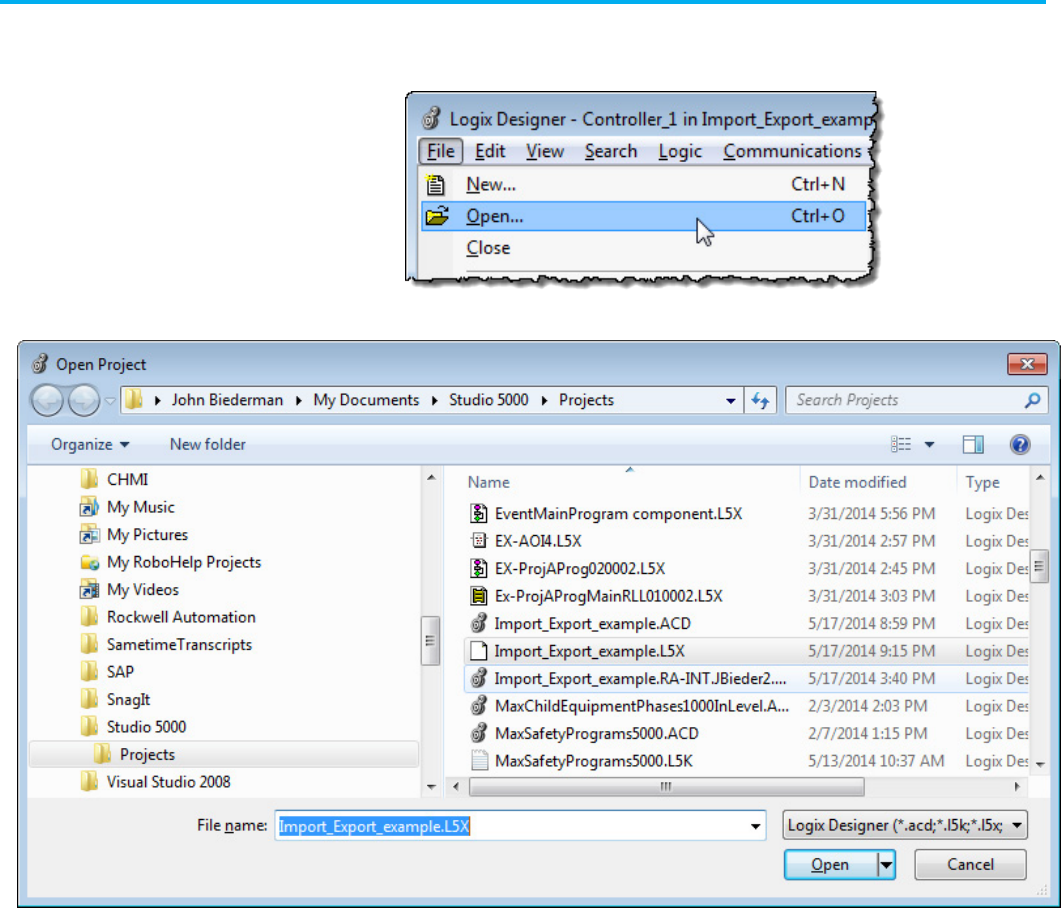

1. In the Logix Designer application, from the File menu, choose Open.

Import an .L5K text file

Chapter 1 Import and export files

Publication 1756-RM014B-EN-P - November 2023 25

The Open Import Project dialog box opens.

2. Select the .L5K text file you want to import and select Open.

Chapter 1 Import and export files

26 Publication 1756-RM014B-EN-P - November 2023

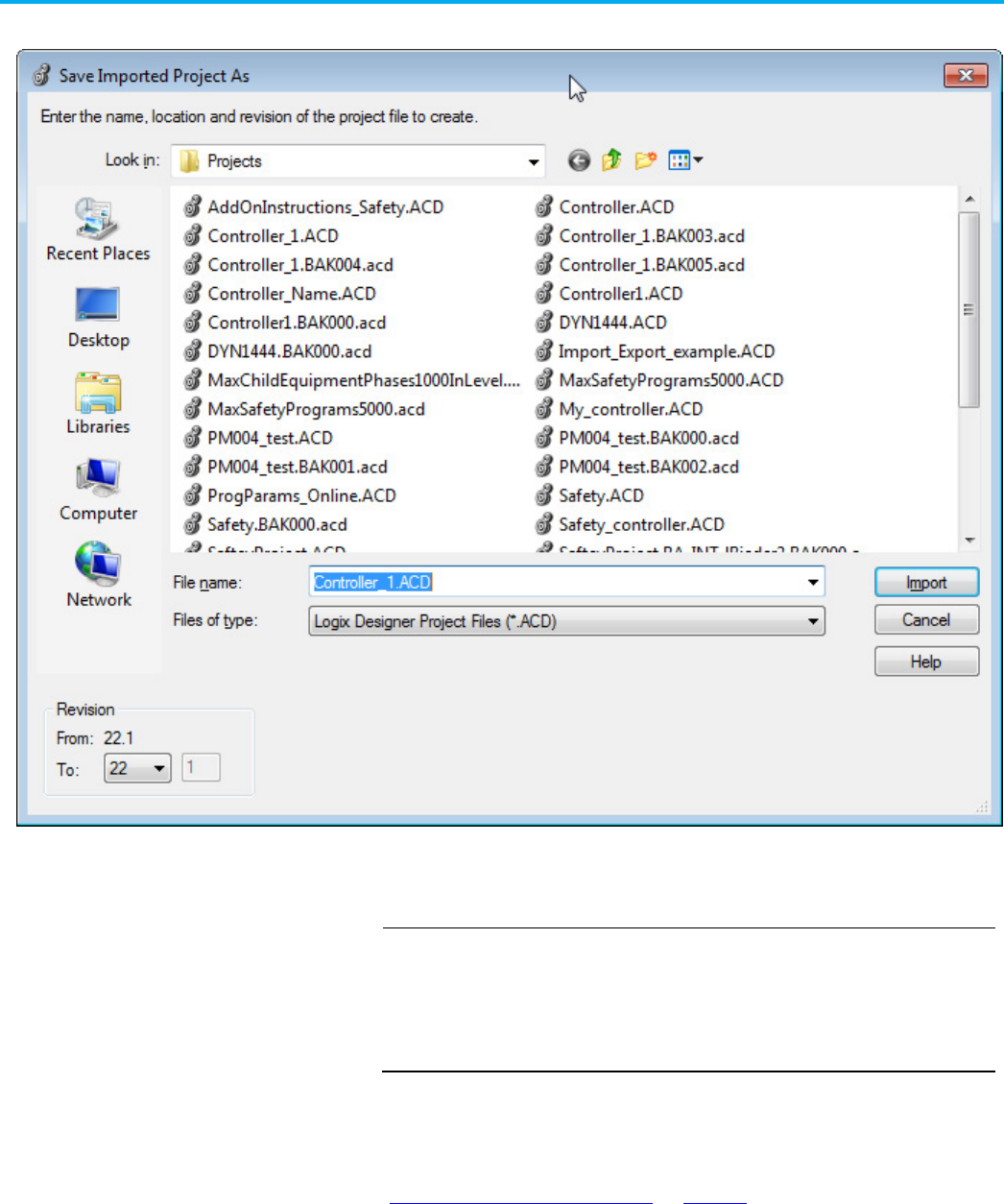

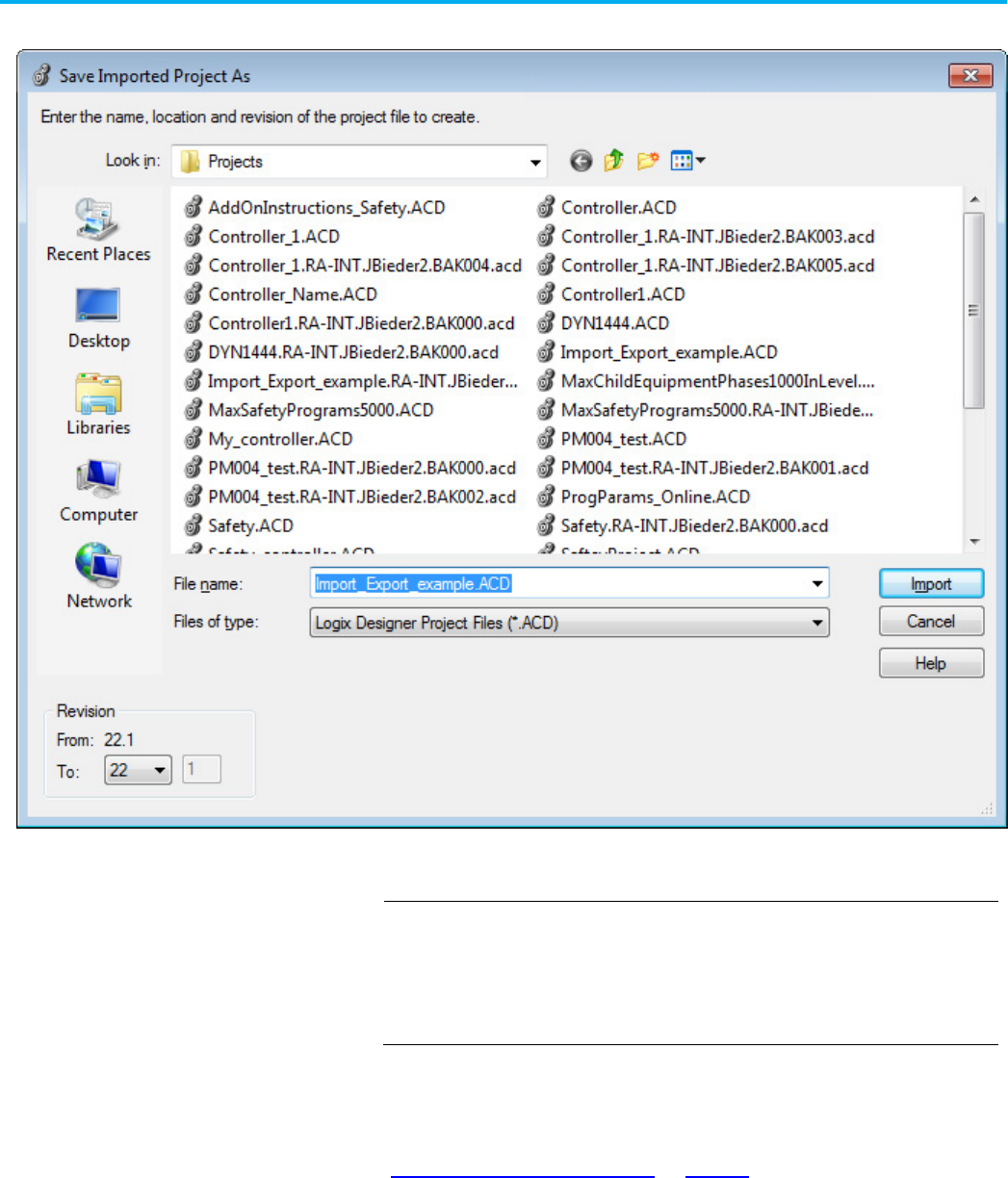

The Save Imported Project As dialog box opens.

3. Browse to where you want to save the imported project.

4. In the File name box, type the name for the imported project and select

Import.

IMPORTANT

If you import a project that has forces, the project defaults to

Forces Disabled

,

even if the project was exported with

Forces Enabled

.

When you import an .L5K file, the project changes so that you cannot go online

and access a previously downloaded controller. You must first upload from or

download to the controller. See

Maintaining Controller Access

..

See also

Maintaining Controller Access on page 39

Chapter 1 Import and export files

Publication 1756-RM014B-EN-P - November 2023 27

For projects with controllers that support OPC UA access, Logix Designer

exports the OpcUaAccess attribute for L5K elements that represent a tag.

These tags are included in the exported output:

• Tag elements (items in TAG collections in controller scope and

program scope)

• ConfigData (corresponds to Config Tag)

• InputData (corresponds to Input Tag)

• OutputData (corresponds to Output Tag)

The OpcUaAccess attribute is exported only when the OPC UA access of an

element representing a tag is different from the default value (None).

The OpcUaAccess attribute is exported also for alias tags.

Tip: During import, the OPC UA access of alias tags is ignored because alias tags have the same OPC

UA access as the tags to which they are pointing.

You can export a project to an XML file and use a text or XML editor to modify

the project. The exported file will be an .L5X format.

Do these steps to export from a project to an .L5X XML file.

1. Make sure the project you want to export from is already open.

2. In the Logix Designer application, select File > Save As.

Export a project to an .L5K

text file for projects with

OPC UA Access

Export a Project to an .L5X

XML File

Chapter 1 Import and export files

28 Publication 1756-RM014B-EN-P - November 2023

The Save As dialog box opens.

3. In the File name box, type the name of the file.

4. From the Save as type list, select.L5X file format and click Save.

Important:

The application automatically saves any unsaved edits when you select

OK

.

For projects with controllers that support OPC UA access, Logix Designer

exports the OpcUaAccess attribute for L5X elements that represent a tag.

These tags are included in the exported output regardless of the tags’ OPC UA

Access value:

• Tag (controller scope and program scope)

• ConfigTag

• InputTag

• OutputTag

The OpcUaAccess attribute is exported also for alias tags.

Tip: During import, the OPC UA access of alias tags is ignored because alias tags have the same OPC

UA access as tags to which they are pointing.

Import controller information from a saved XML file that has an .L5X

extension and is a full controller export. This lets you use any editor to create

a project.

Export a project to an .L5X

text file for projects with

OPC UA Access

Import an .L5X XML File

Chapter 1 Import and export files

Publication 1756-RM014B-EN-P - November 2023 29

Do these steps to import a controller .L5X XML file into a project.

1. In the Logix Designer application, select File > Open.

The Open Project dialog box opens.

2. In the File name box, select the .L5X controller file you want to import

and select Open.

Chapter 1 Import and export files

30 Publication 1756-RM014B-EN-P - November 2023

The Save Imported Project As dialog box opens.

3. Browse to where you want to save the imported project.

4. In the File name box, type the name for the project and select Import.

IMPORTANT

If you import a project that has forces, the project defaults to

Forces Disabled

,

even if the project was exported with

Forces Enabled

.

When you import an .L5X file, the project changes so that you cannot go online

and access a previously downloaded controller. You must first upload from or

download to the controller. See

Maintaining Controller Access

.

See also

Maintaining Controller Access on page 39

Chapter 1 Import and export files

Publication 1756-RM014B-EN-P - November 2023 31

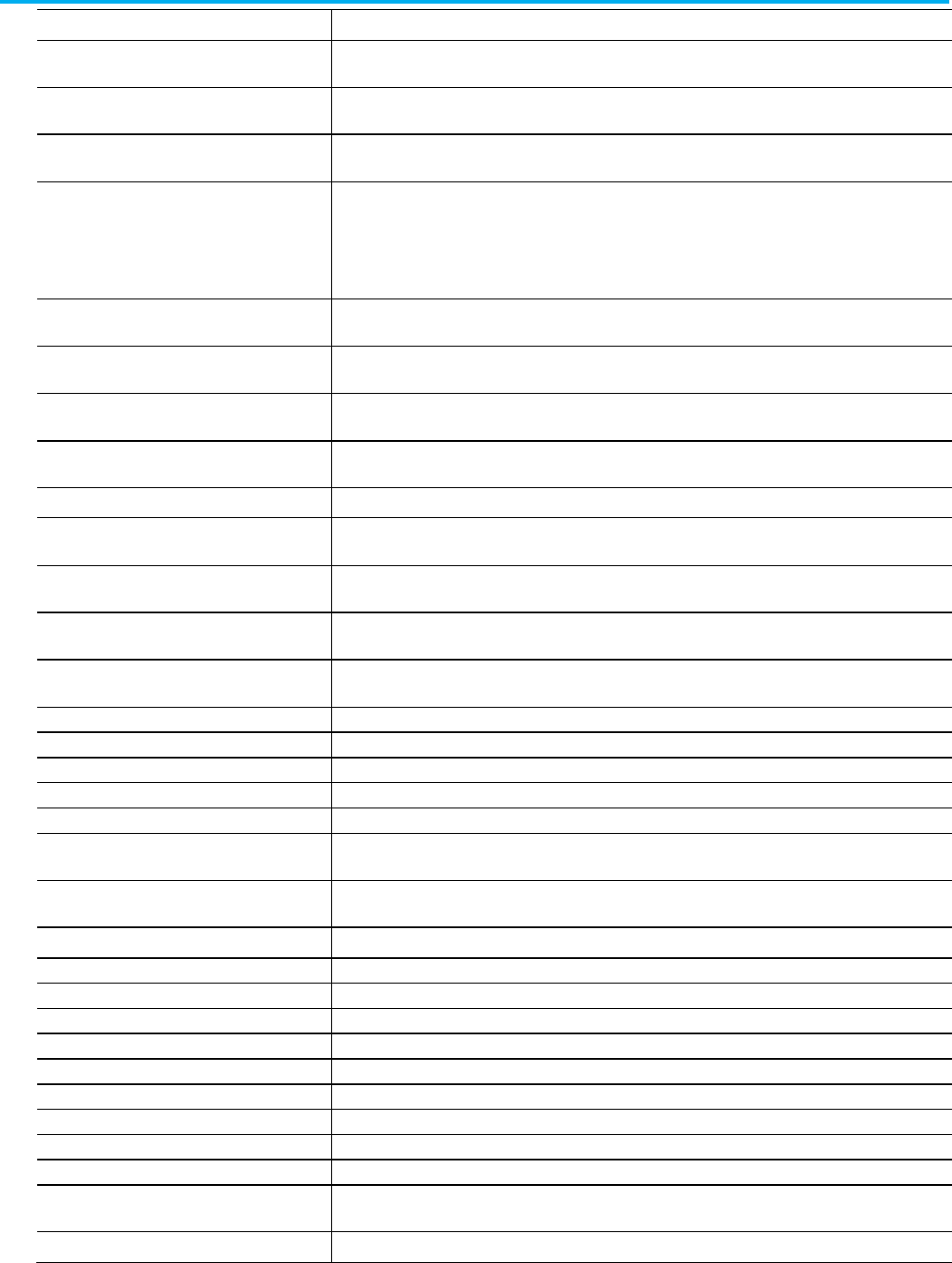

When you have a project open, you can export tags and logic comments to a

structured file that separates values with commas (.CSV file) or that separates

values with tabs (.TXT Unicode file). You can then use other applications, such

as Microsoft Excel or Notepad, to edit the tags and logic comments.

Do these steps to export tags and logic comments to a structured file.

1. Make sure the project from which you want to export tags and

comments is already open.

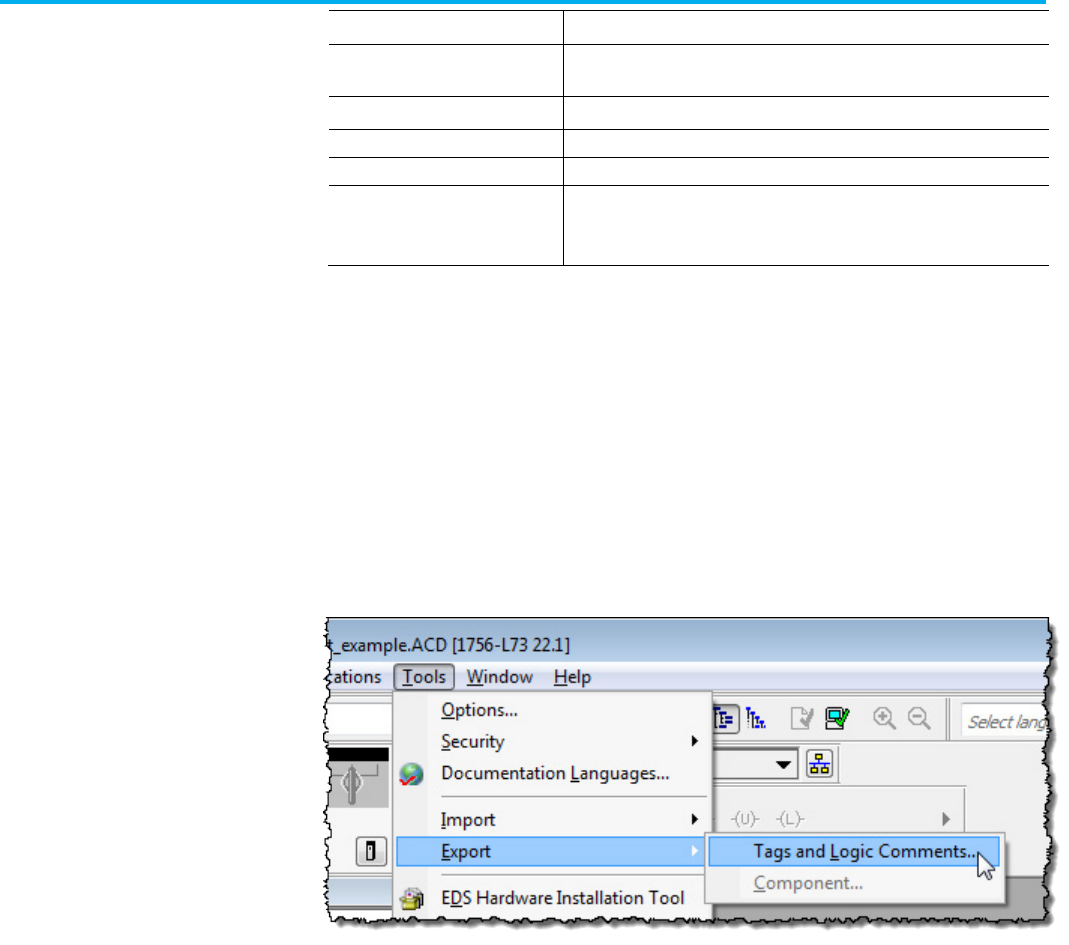

2. In the Logix Designer application, select Tools > Export > Tags and

Logic Comments.

Export to a .CSV or .TXT file

Chapter 1 Import and export files

32 Publication 1756-RM014B-EN-P - November 2023

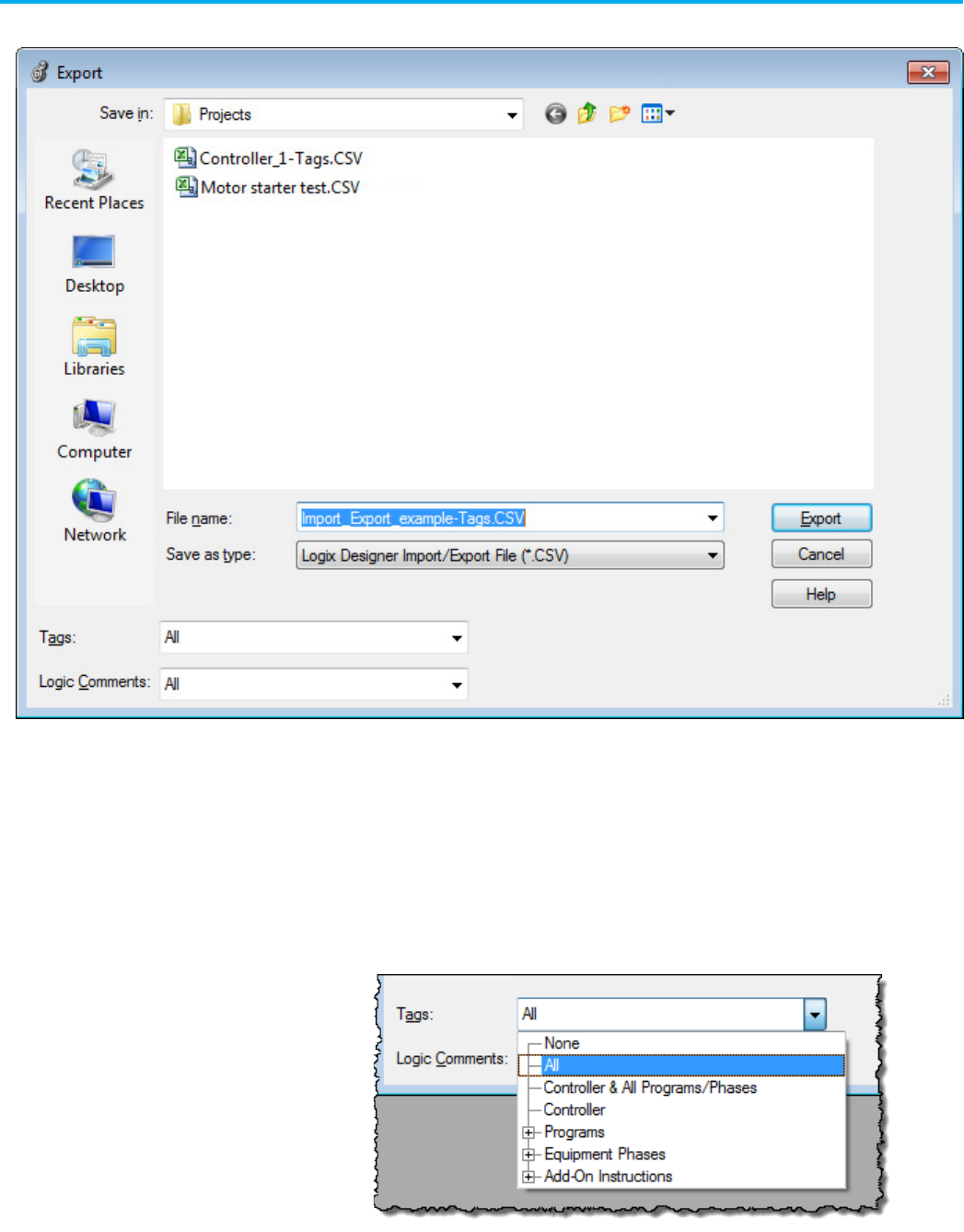

The Export dialog box opens.

3. In the File name box, type the name of the file to be exported.

4. From the Save as type list, select.CSV or .TXT format.

The .TXT import/export format supports double-byte characters, so

you can use this format for all languages, including Chinese, Japanese,

and Korean. The .CSV import/export format does not support

double-byte characters.

5. From the Tags and Logic Comments list, set the scope of the tags and

logic comments to be exported.

6. Select Export.

Chapter 1 Import and export files

Publication 1756-RM014B-EN-P - November 2023 33

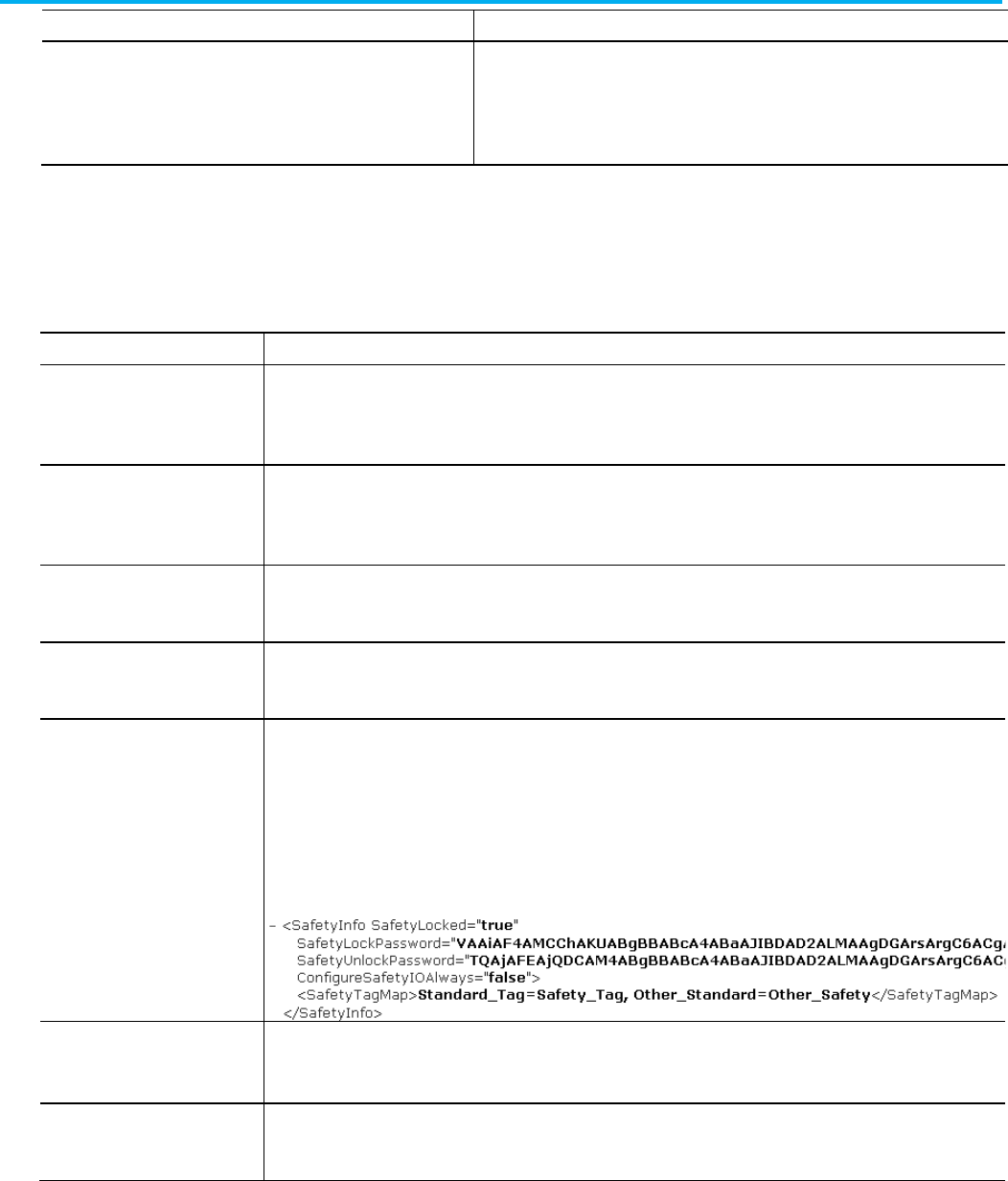

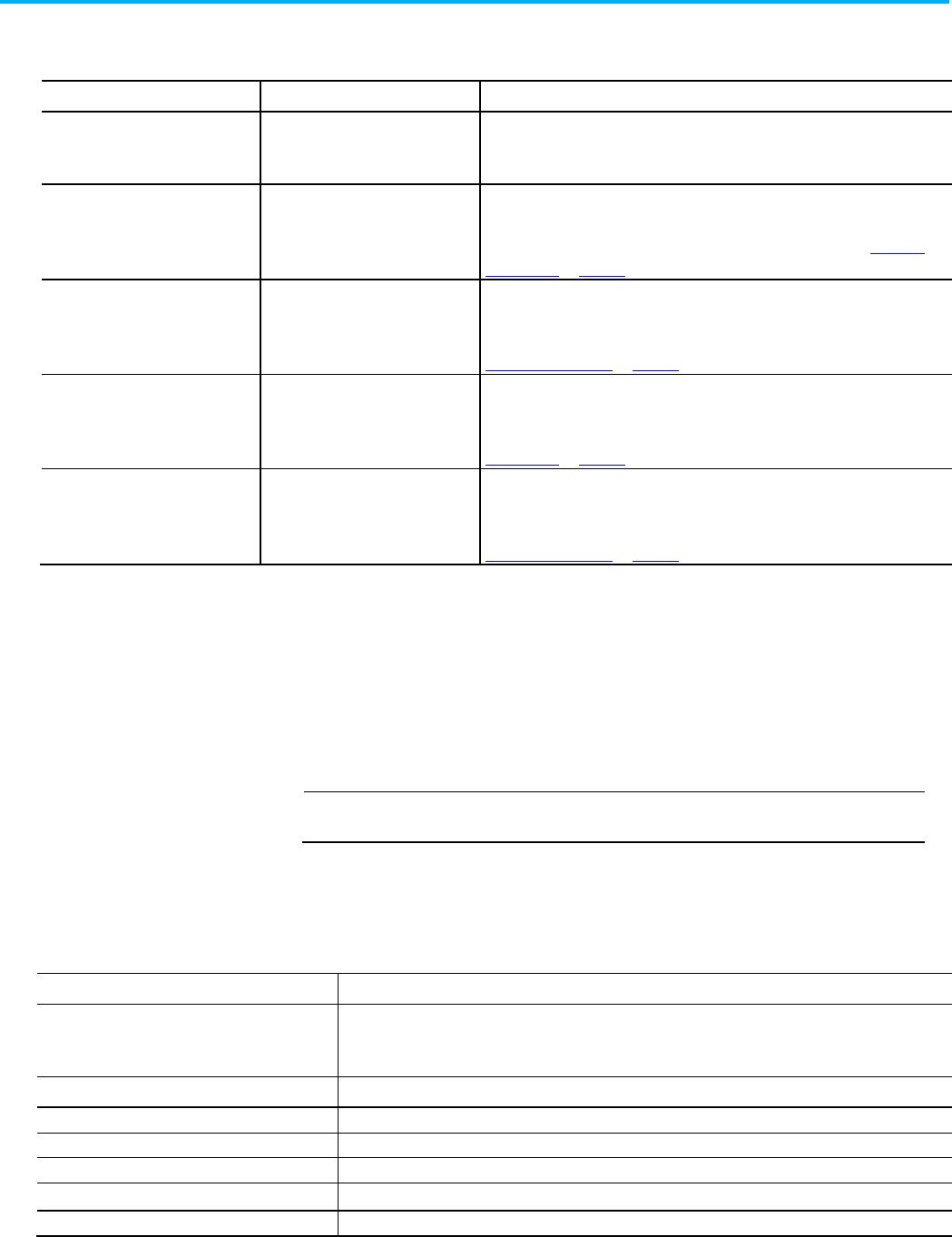

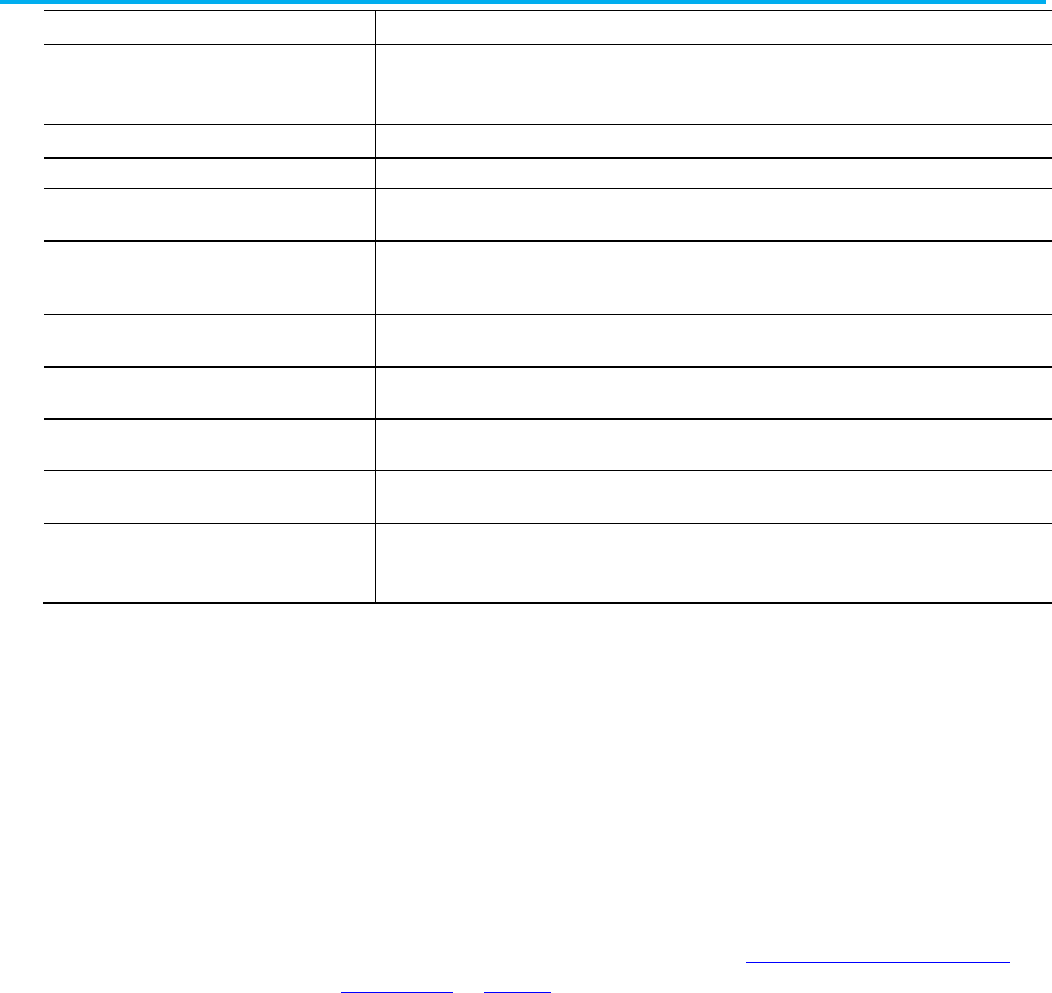

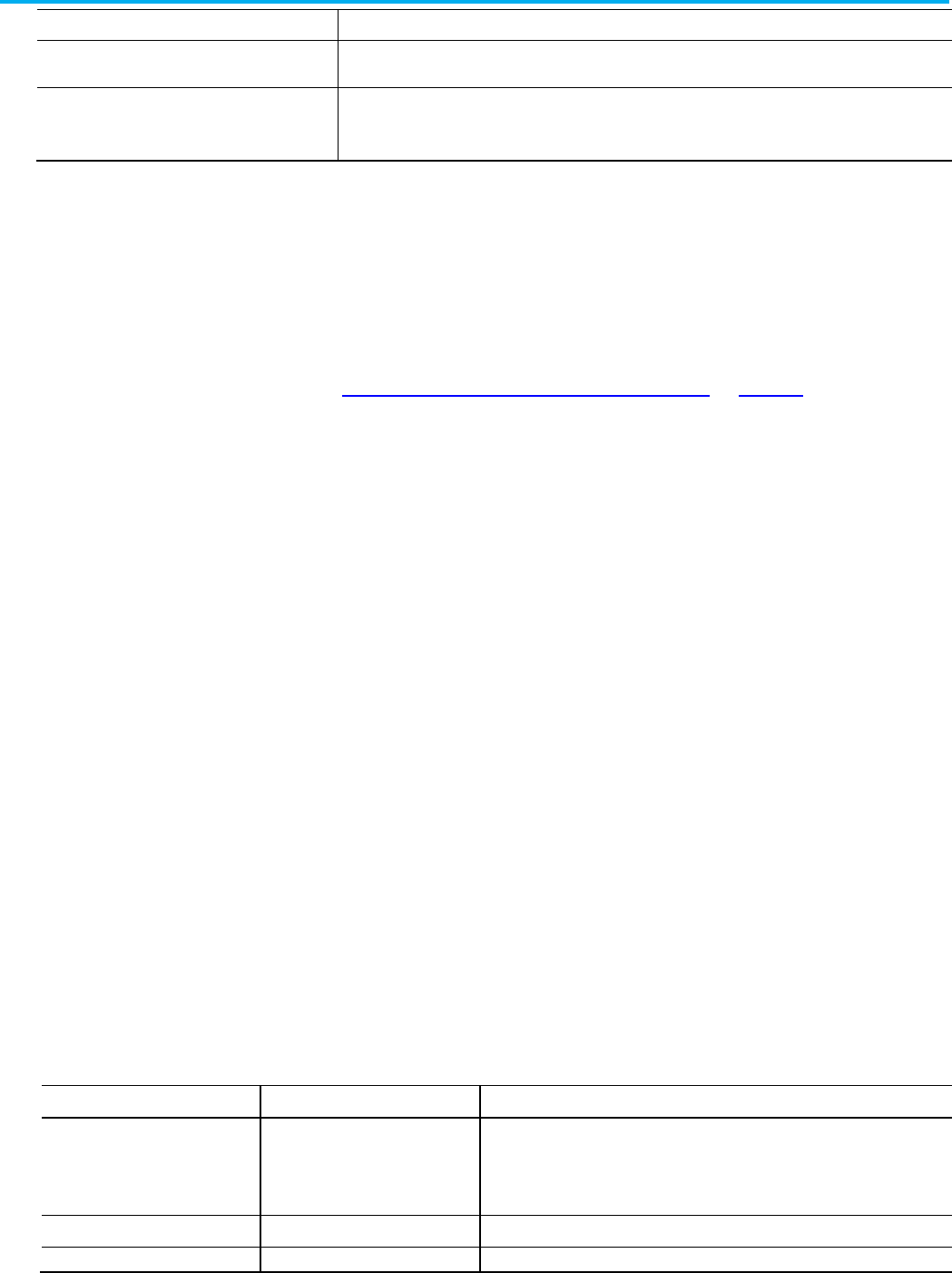

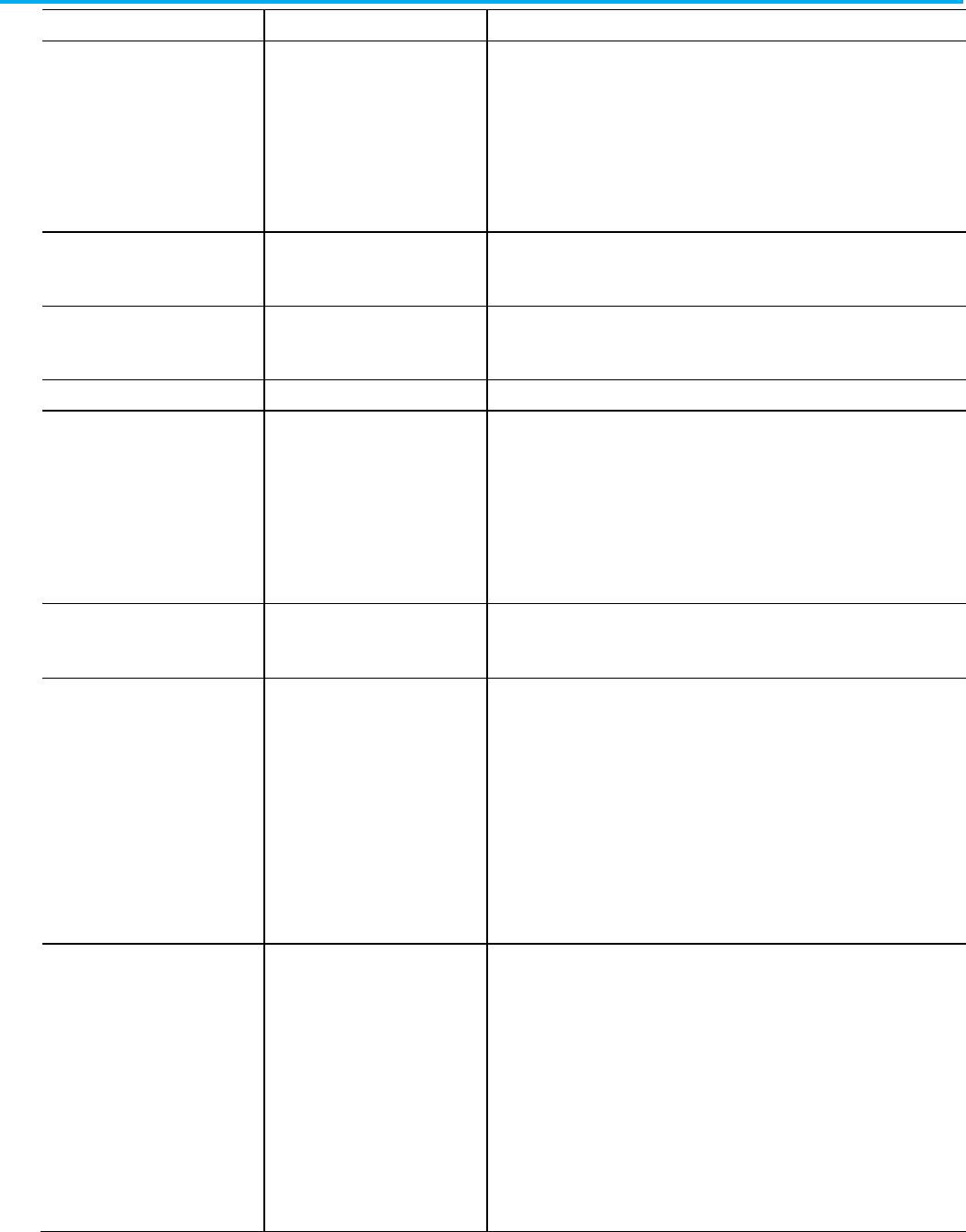

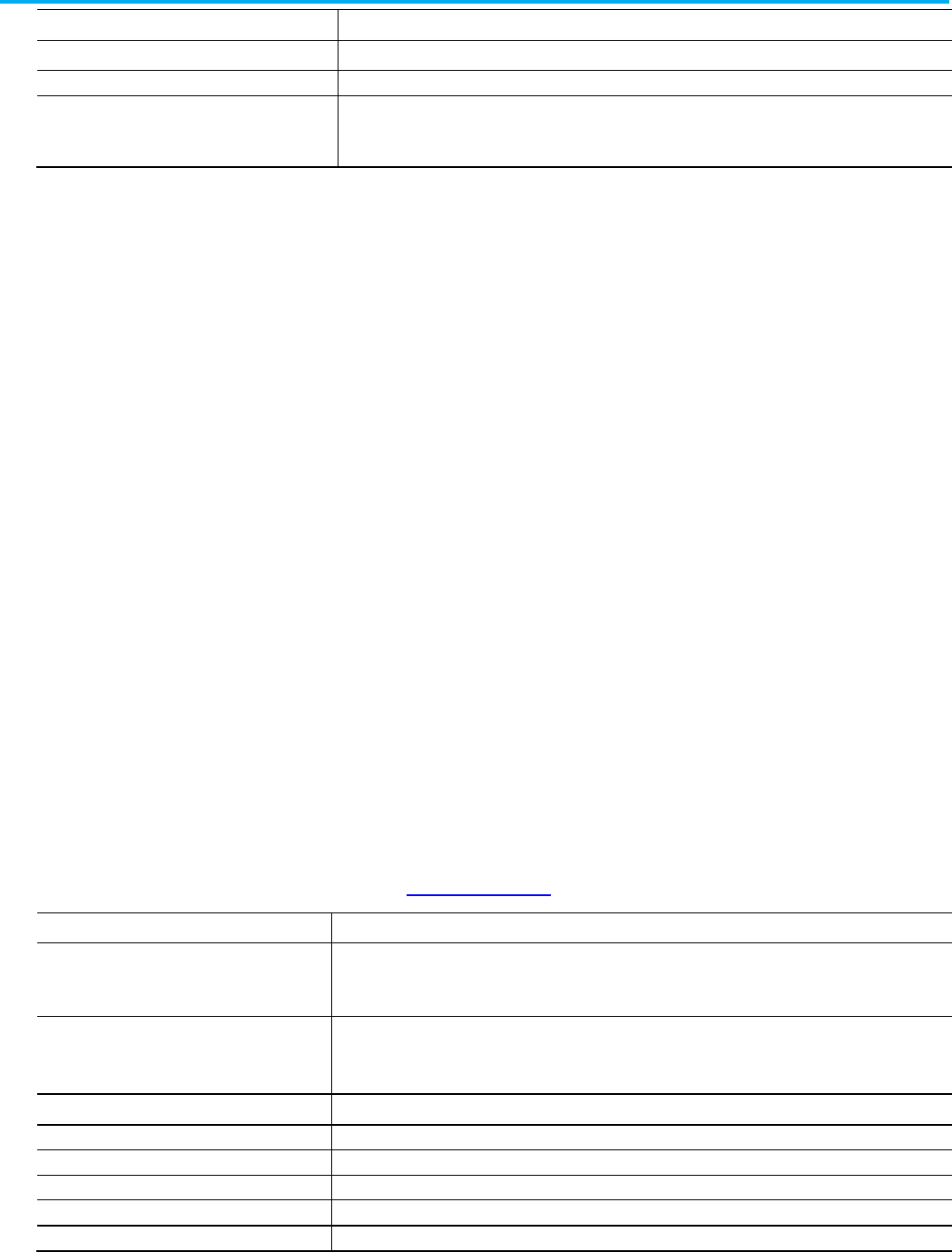

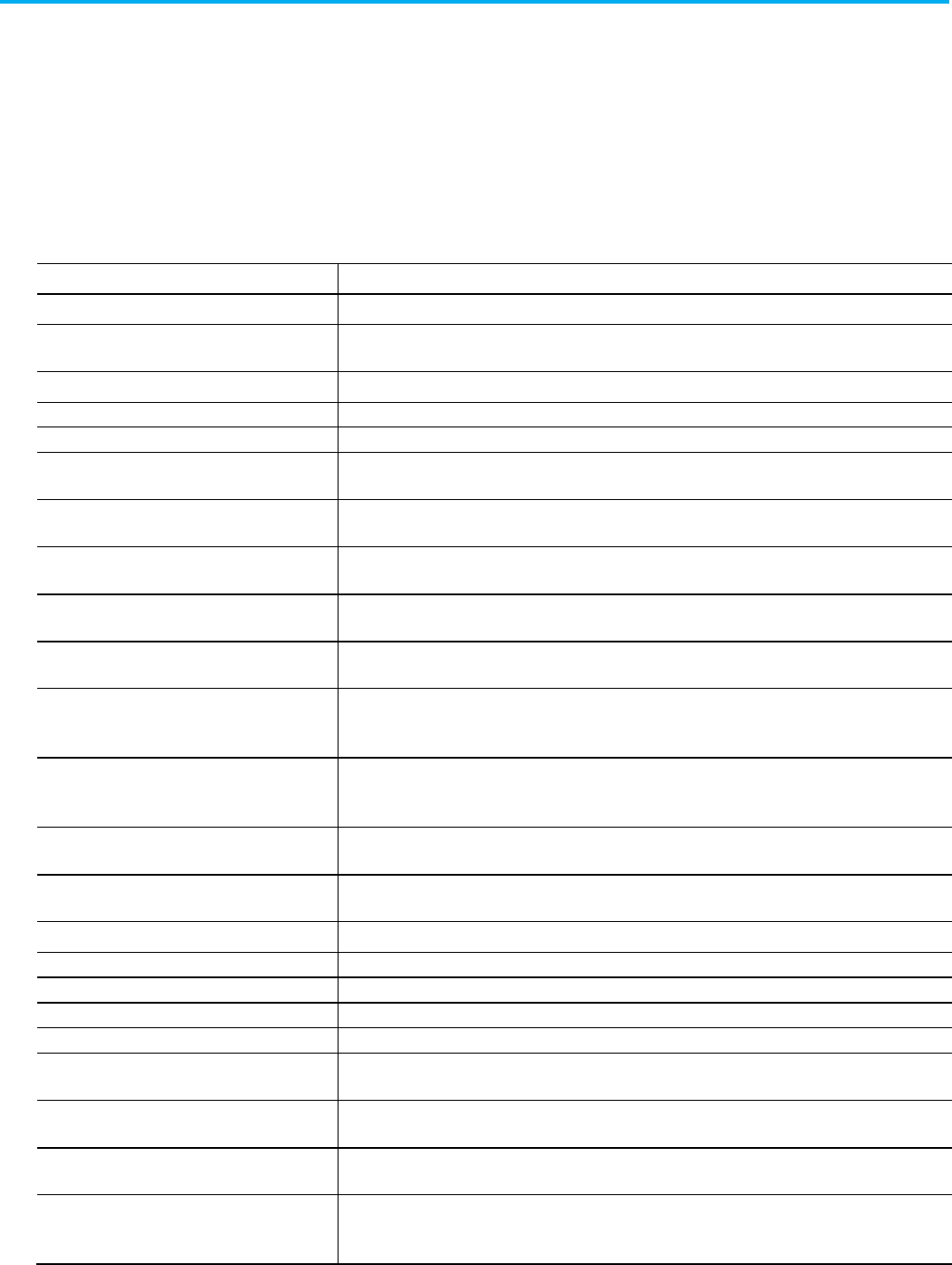

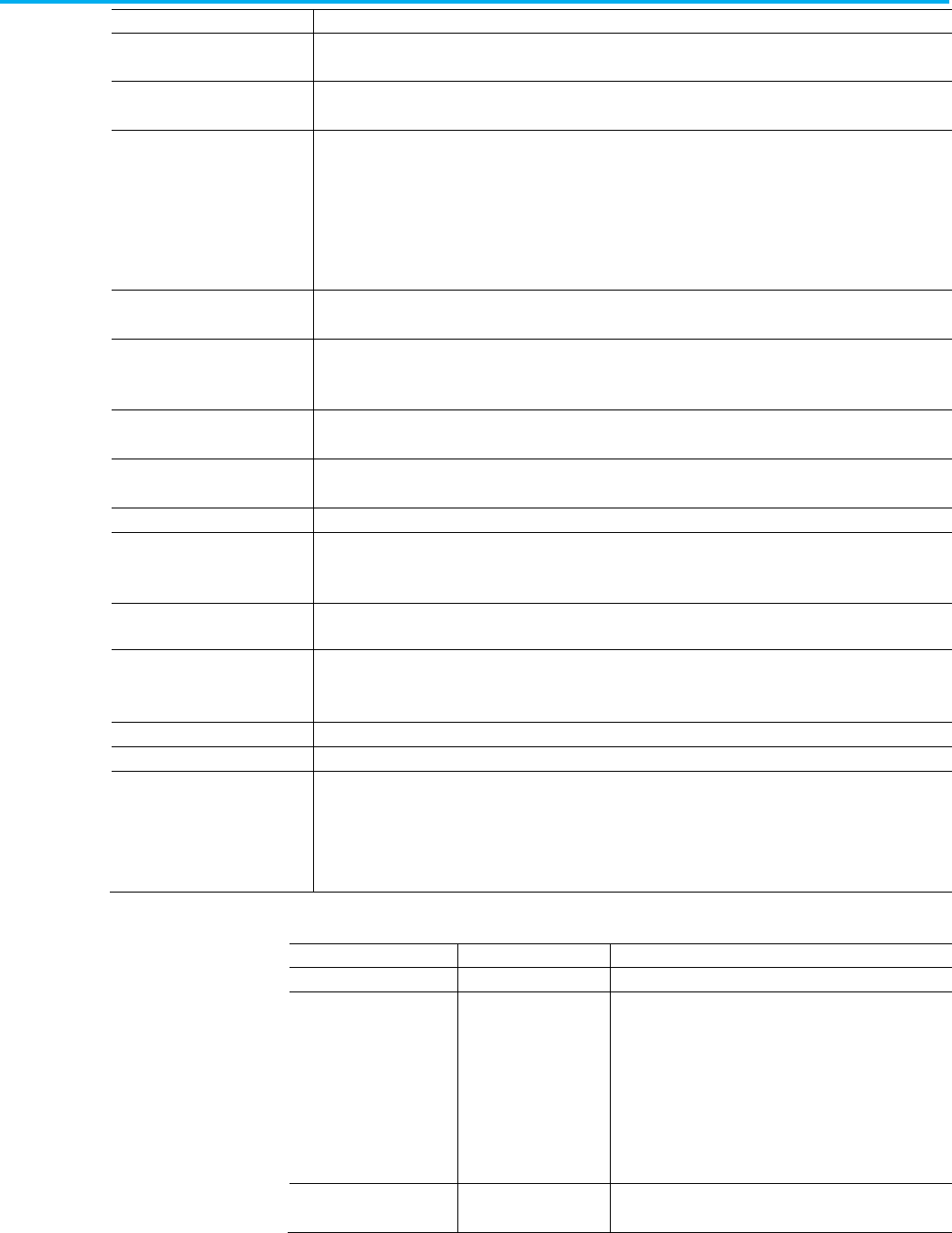

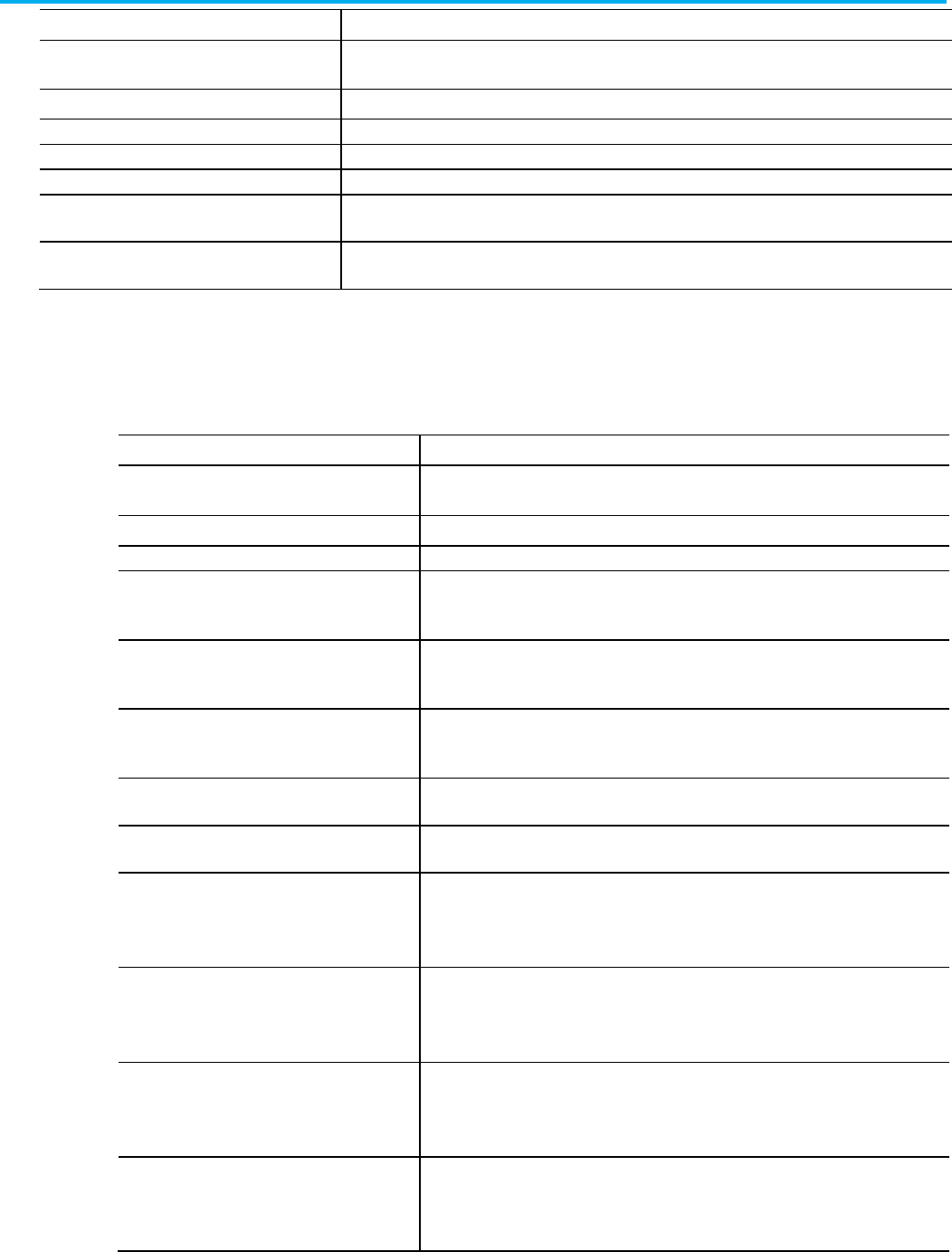

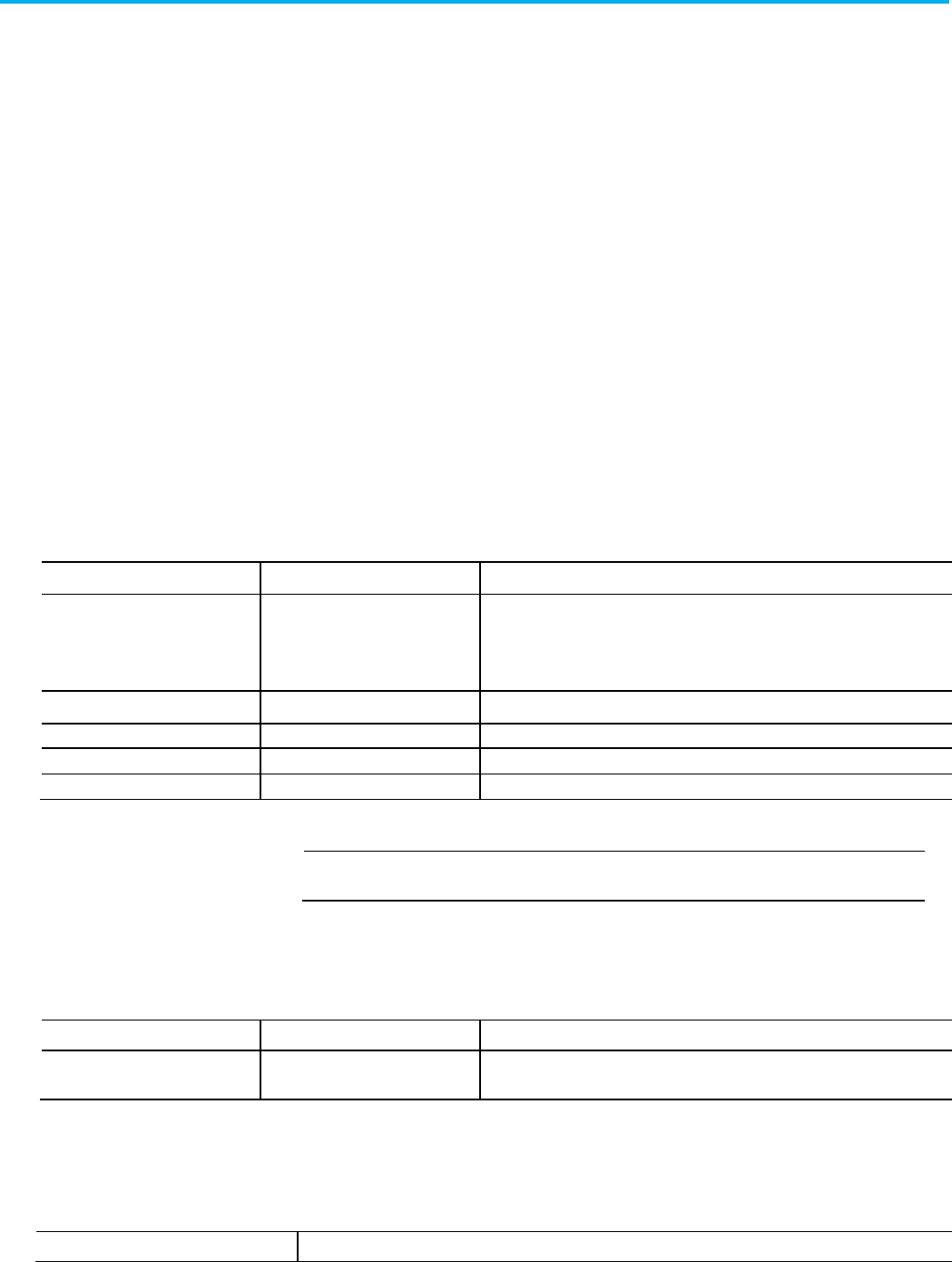

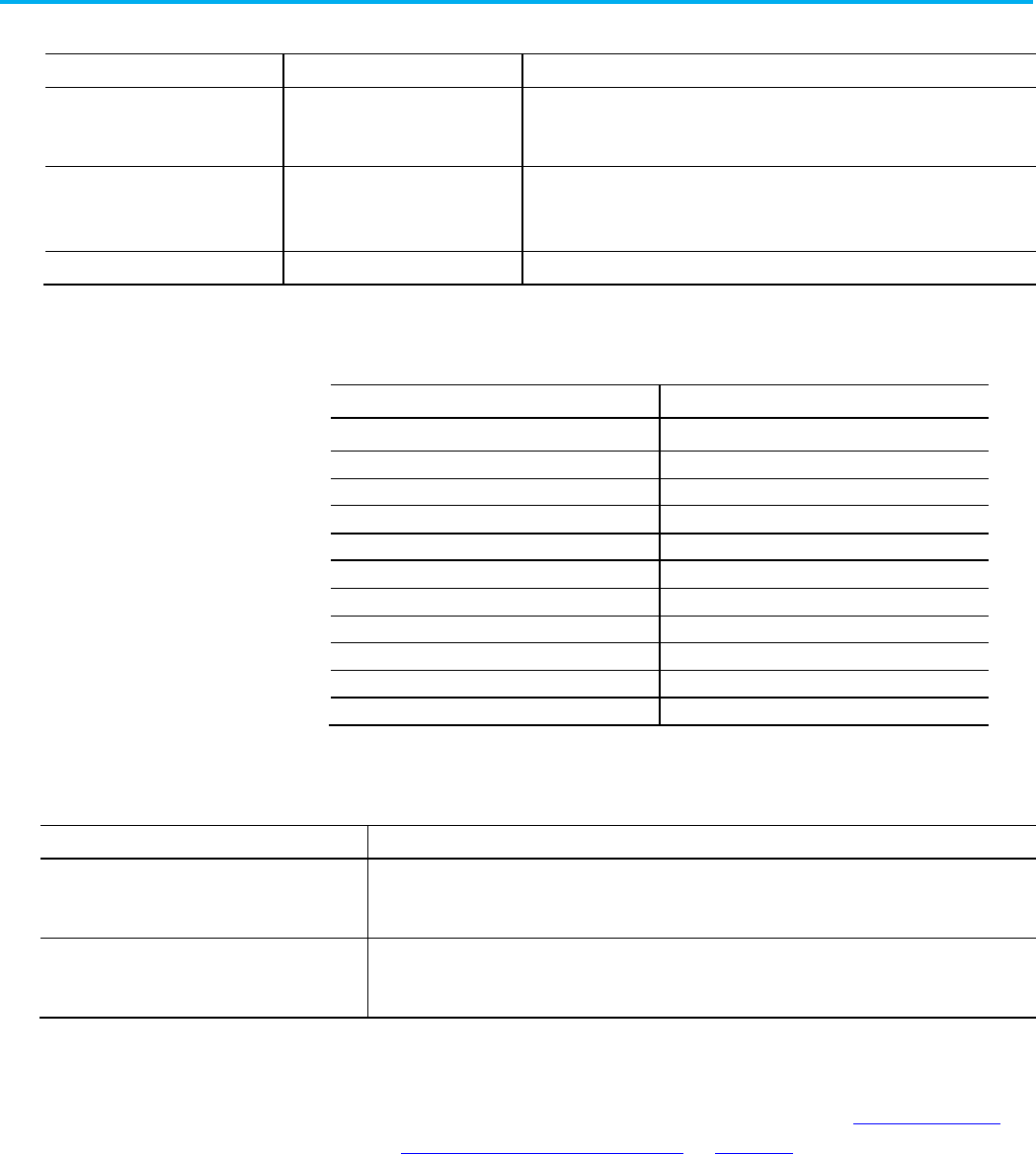

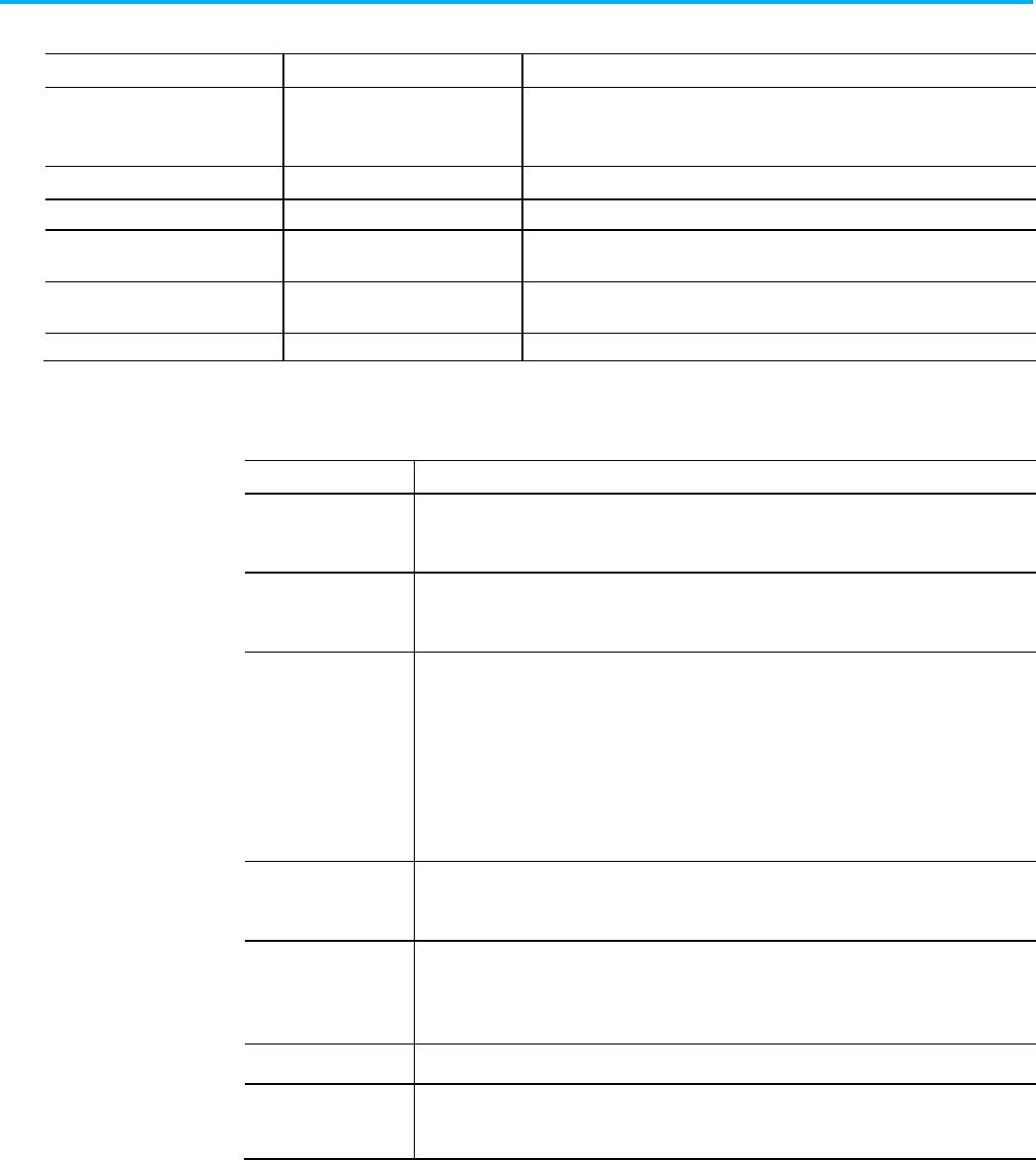

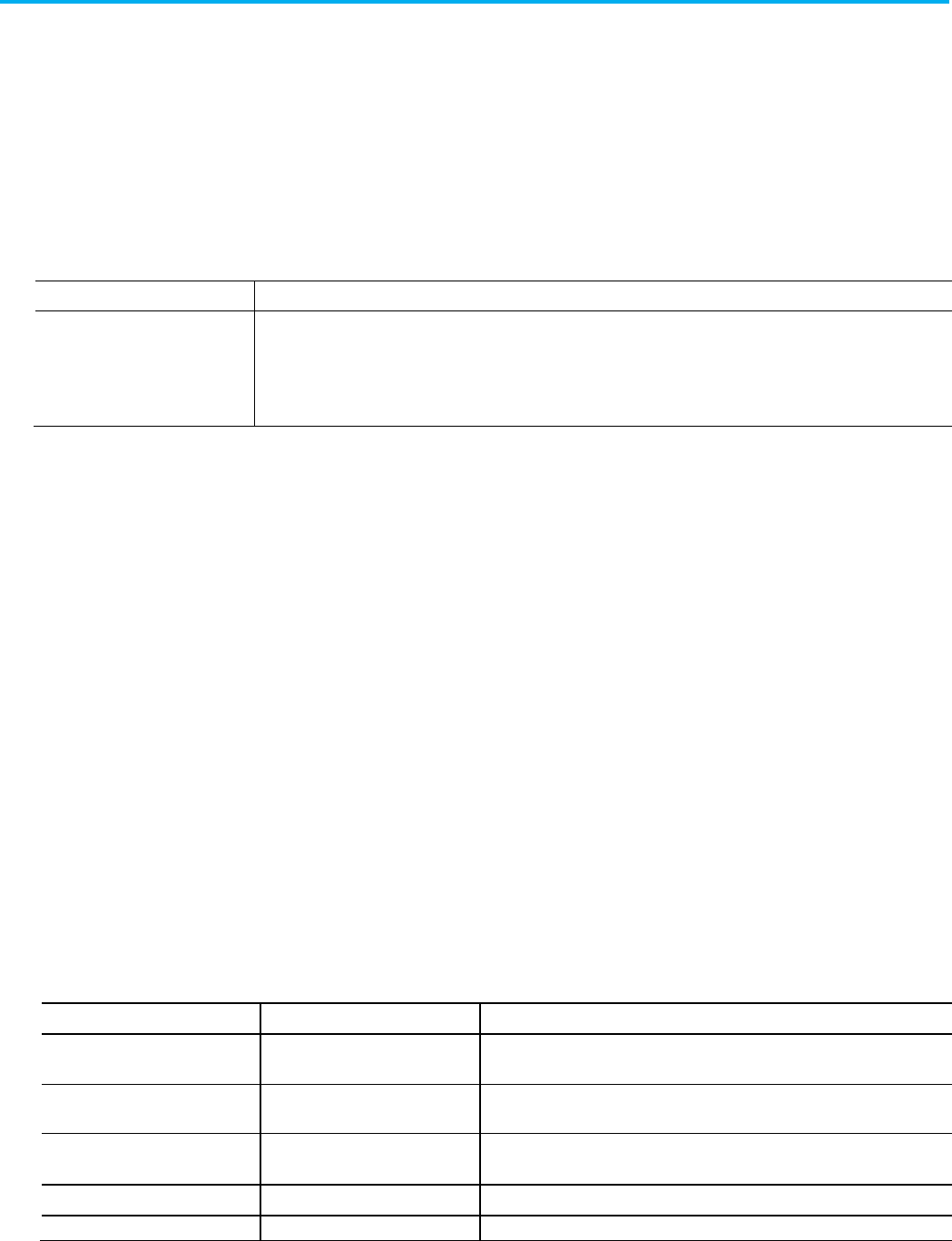

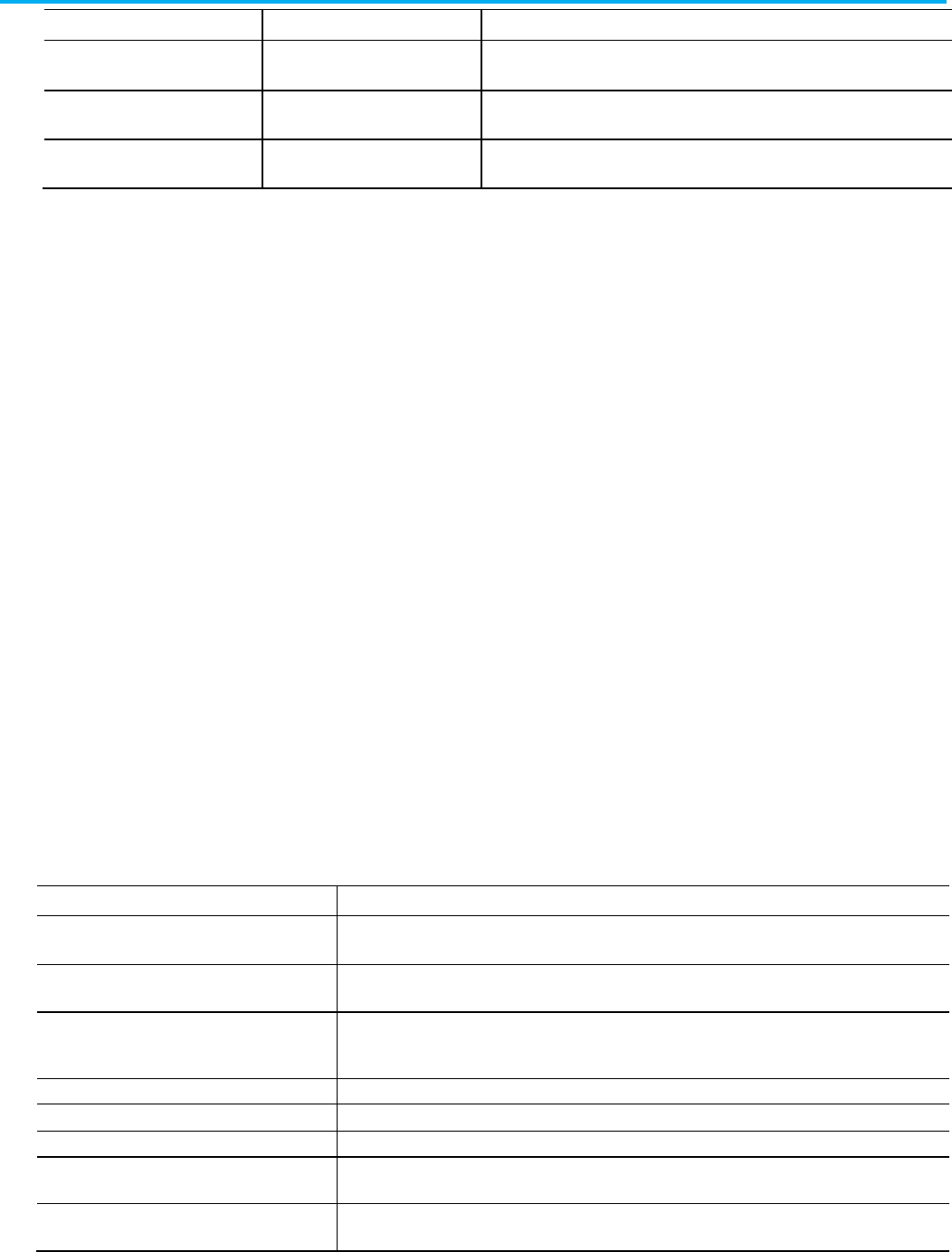

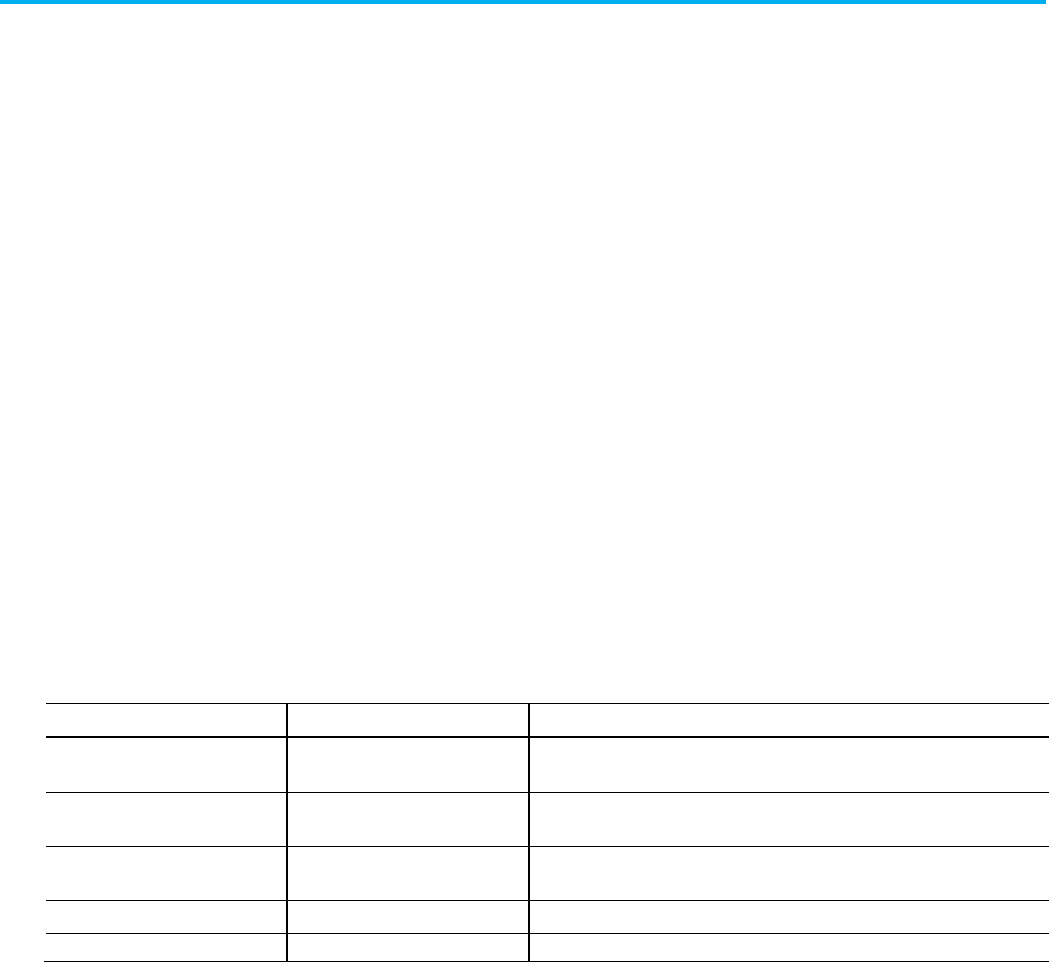

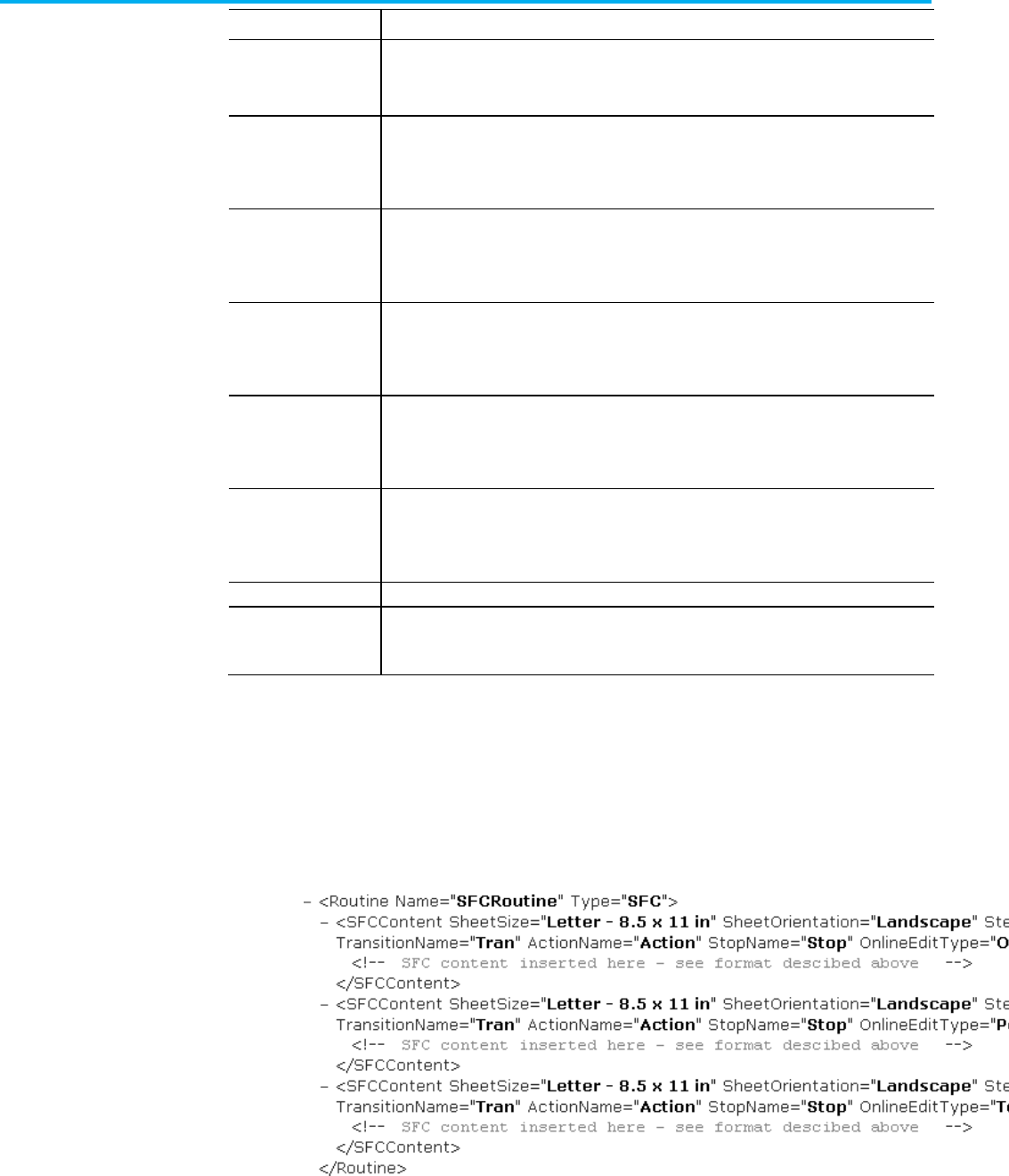

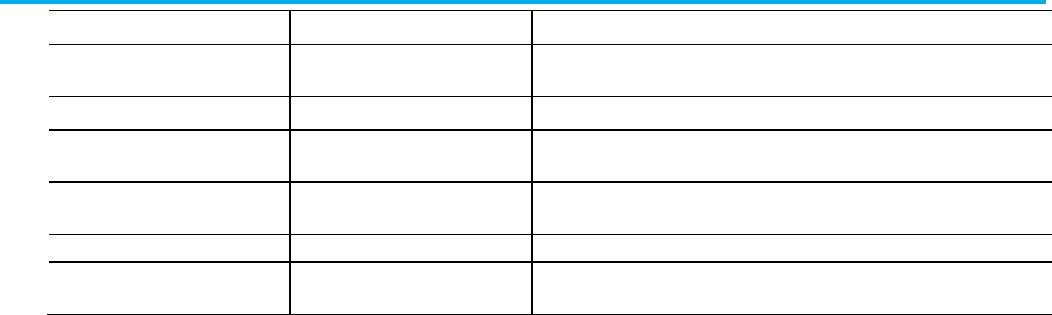

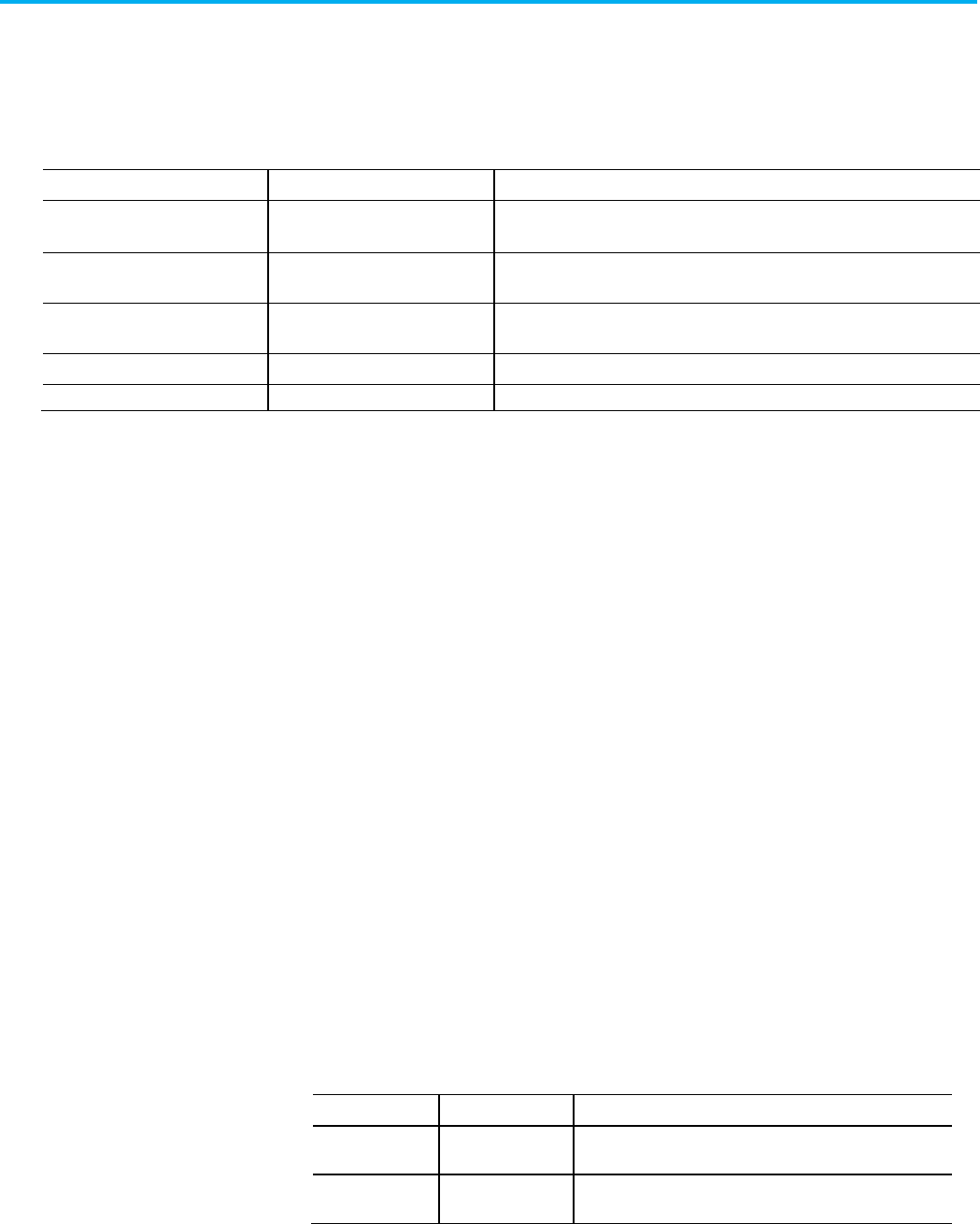

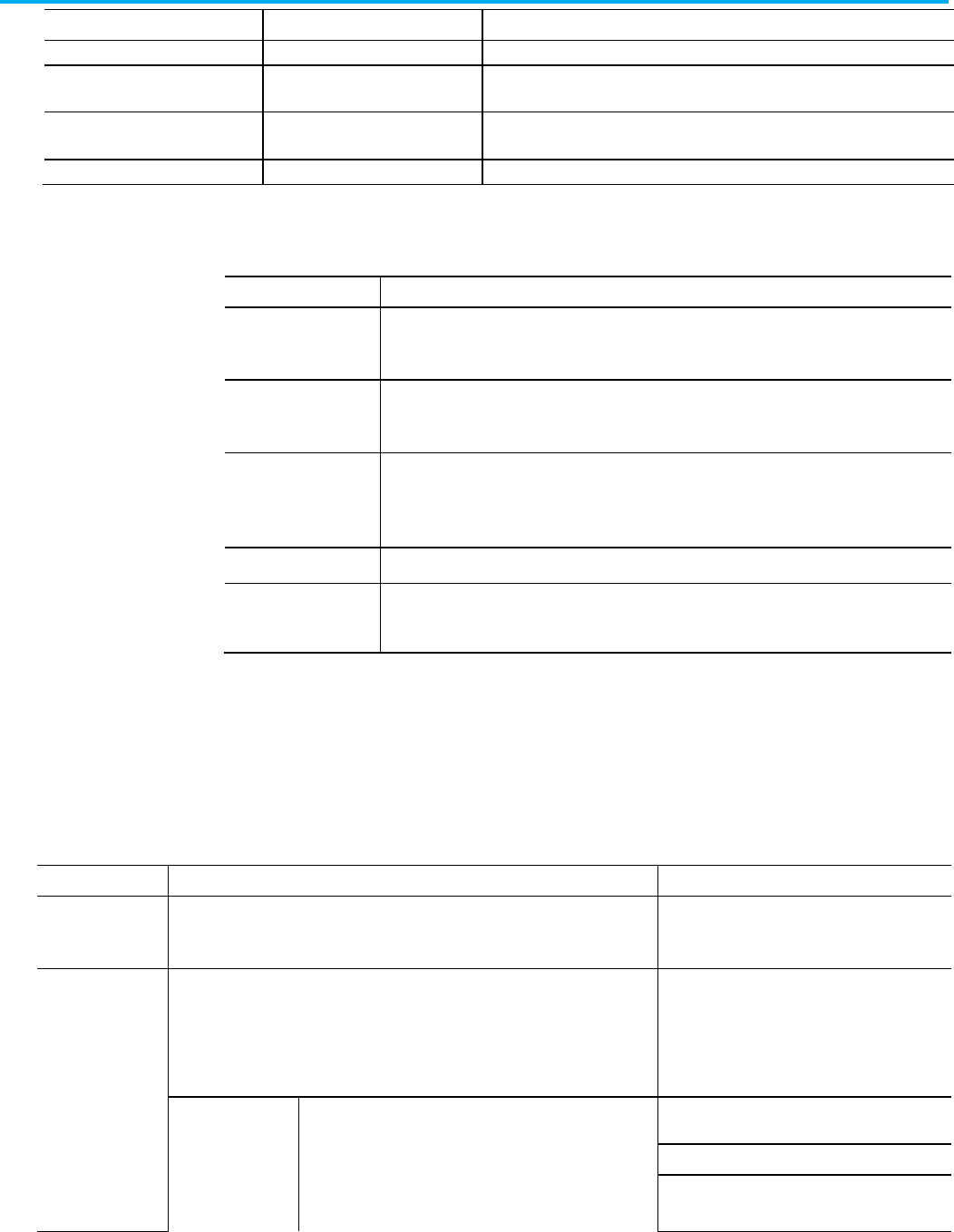

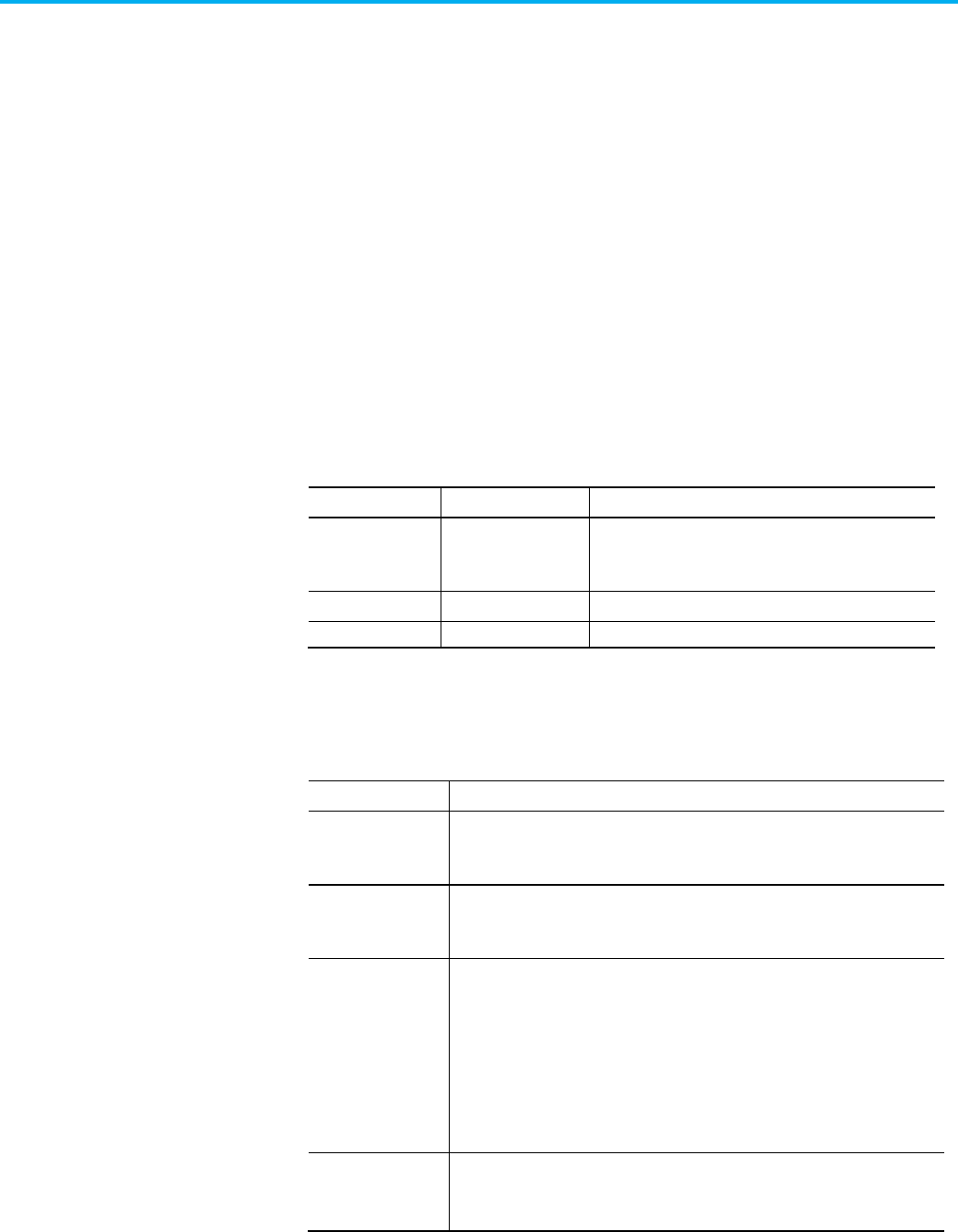

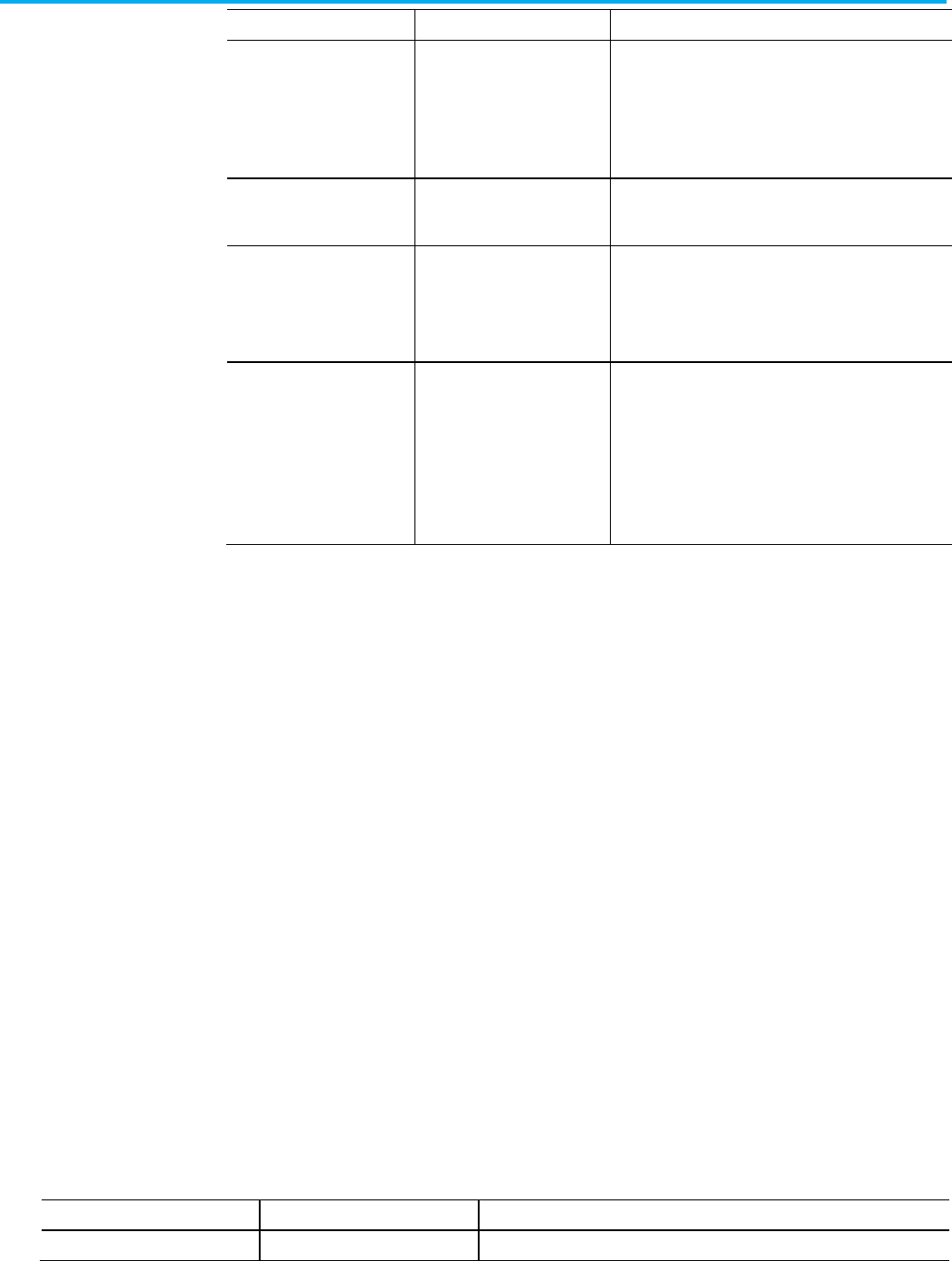

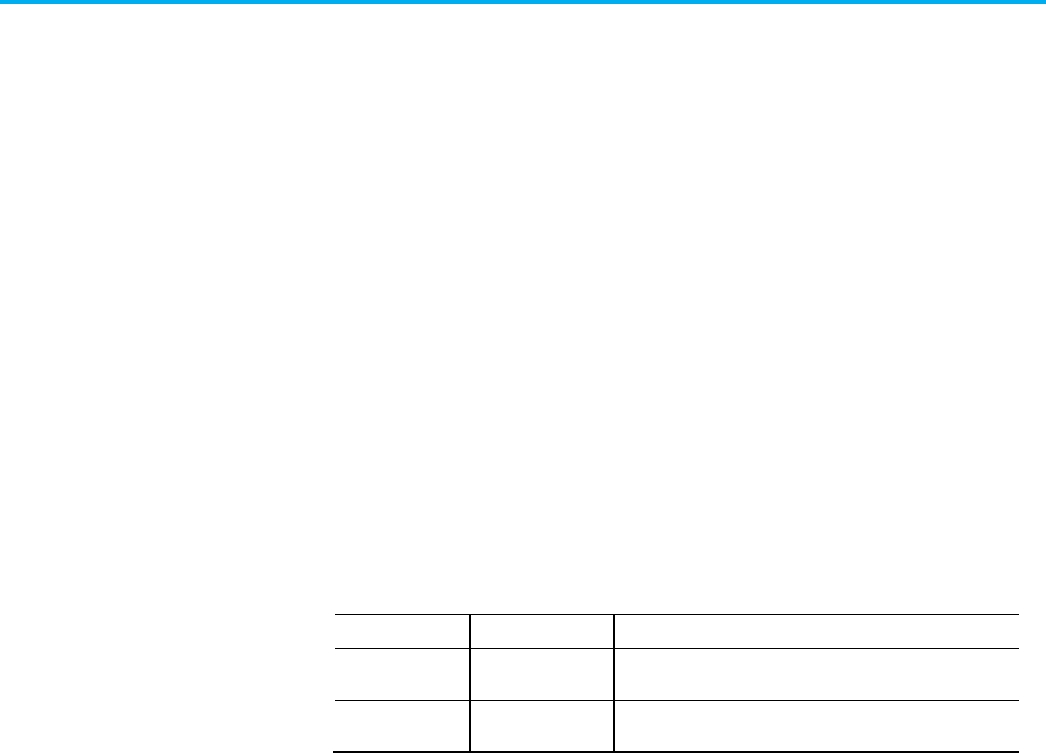

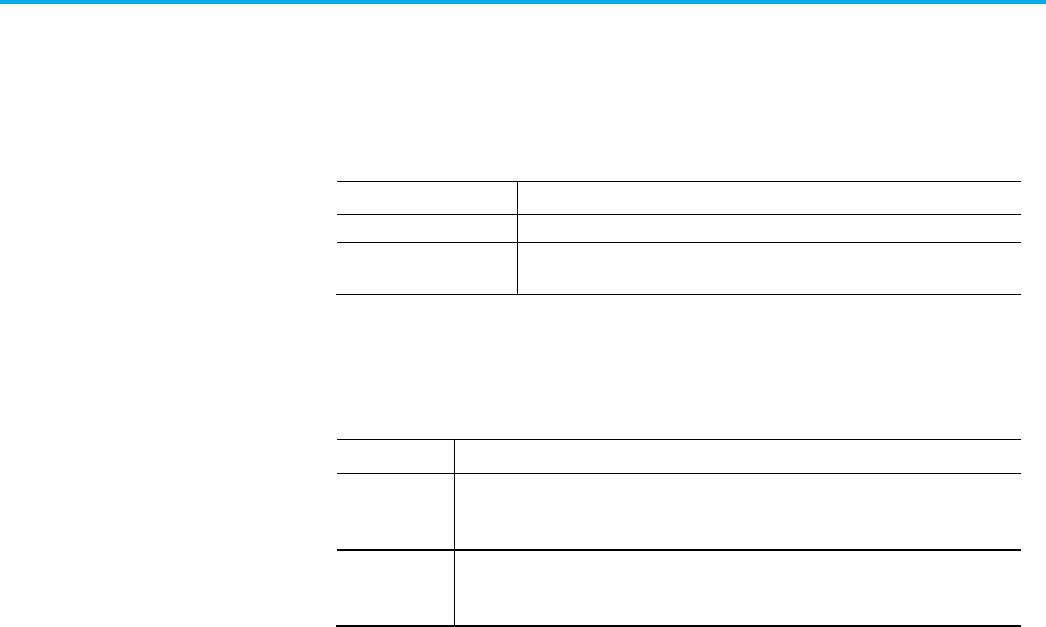

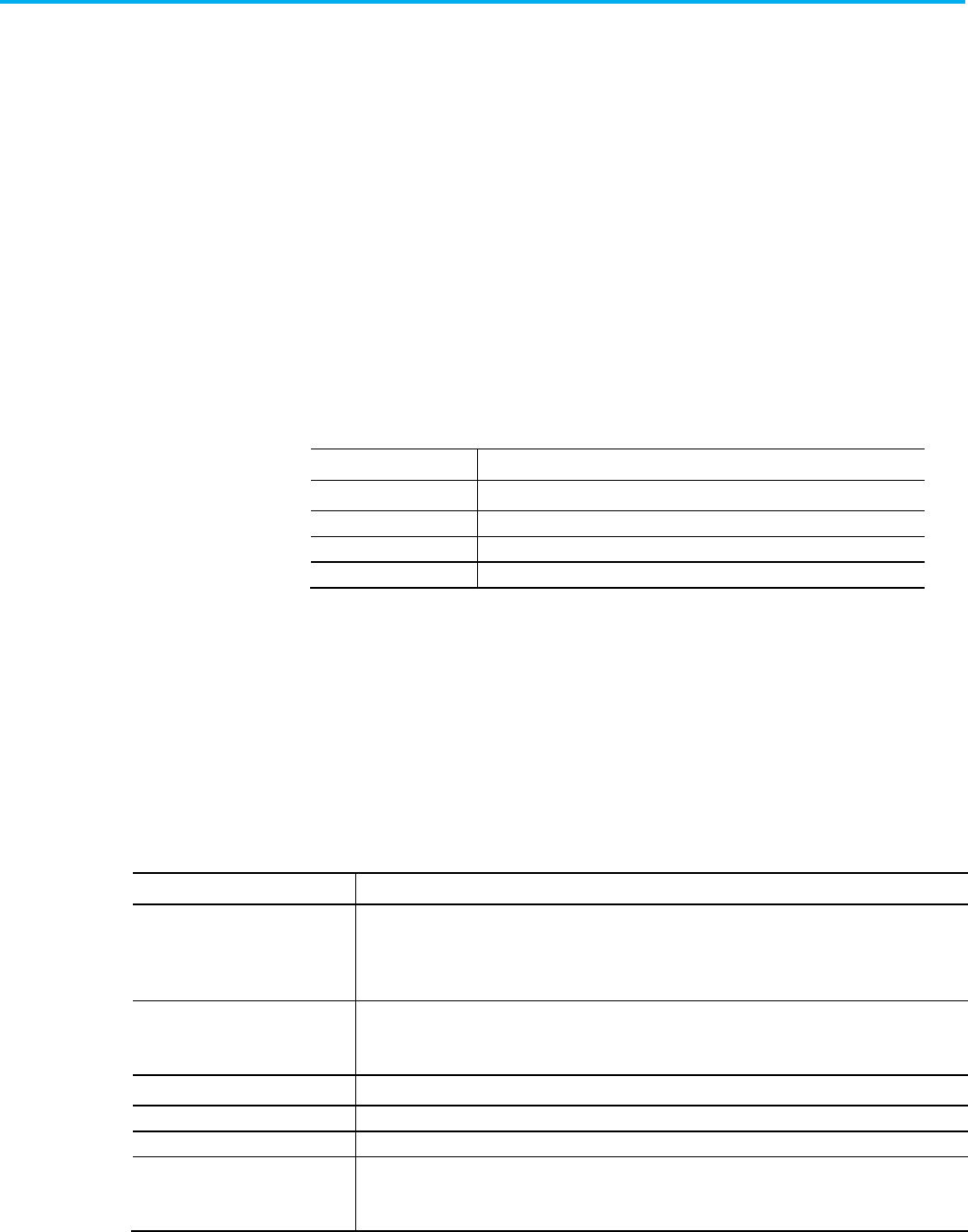

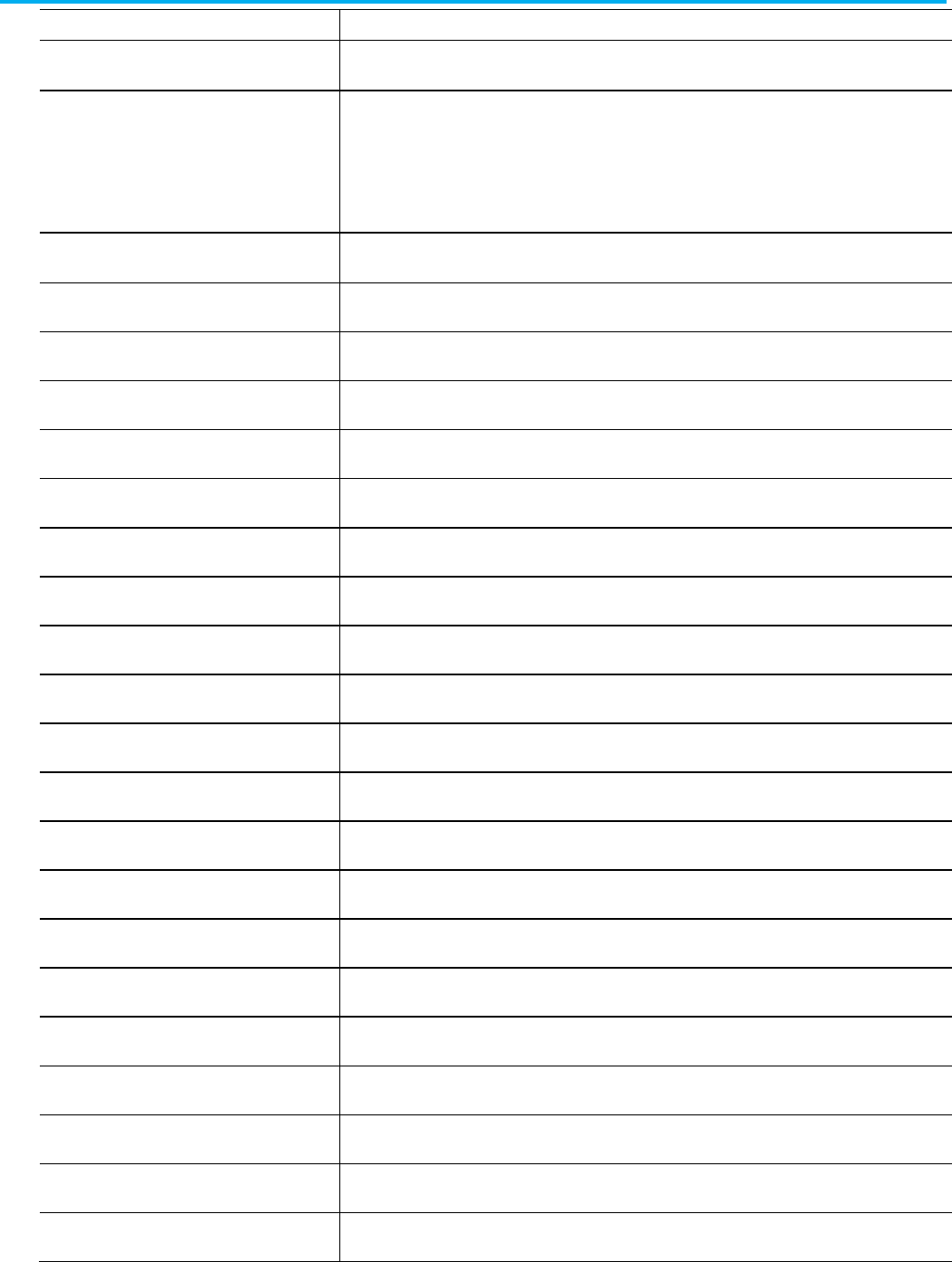

Scope

Exported Material

All

All the tags (controller-scope, program-scope, equipment phase, and Add-On

Instruction) or logic comments in the project

Controller and All Programs/Phases

Tags only; all controller-scope, program-scope, and equipment phase tags

Controller

Tags only; the controller-scoped tags of the project

All Programs/Phases

Logic Comments only; all program and equipment phase comments

Programs

Equipment Phases

Add-On Instructions

The tags or logic comments of a specific program, equipment phase, or

Add-On Instruction

Import tags and logic comments from a saved .CSV file or .TXT file. This lets

you use other applications, such as Microsoft Excel or Notepad, to create and

edit tags

and logic comments.

To import .CSV or .TXT file

1. In the Logix Designer application, select Tools > Import > Tags and

Logic Comments.

Import a .CSV or .TXT file

Chapter 1 Import and export files

34 Publication 1756-RM014B-EN-P - November 2023

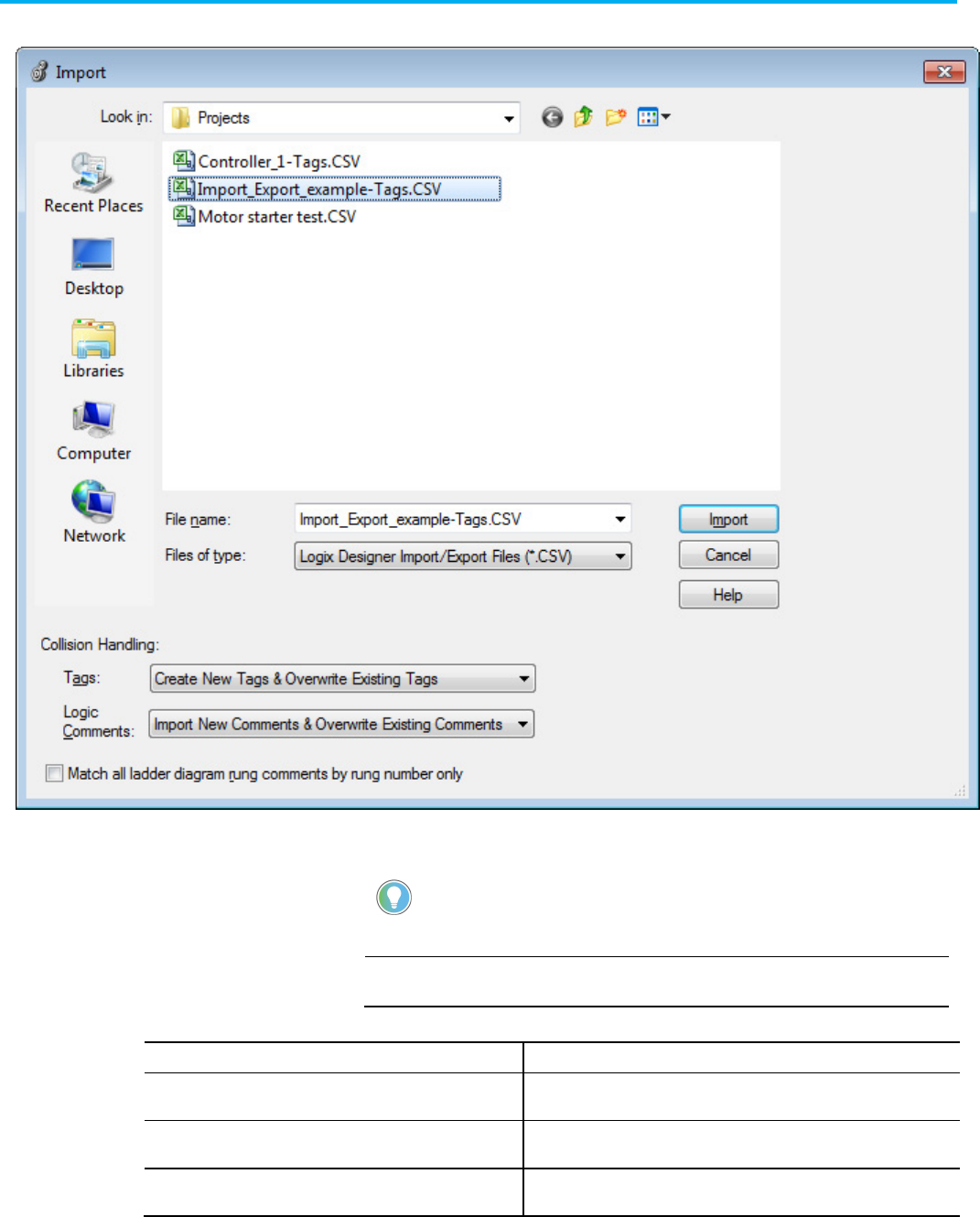

The Import dialog box opens.

2. In the File name box, select the .CSV or .TXT file to import.

3. From the File of type list, select .CSV or .TXT format.

Tip: Use the

File of type

list to filter .CSV or .TXT files in the

Import

dialog box.

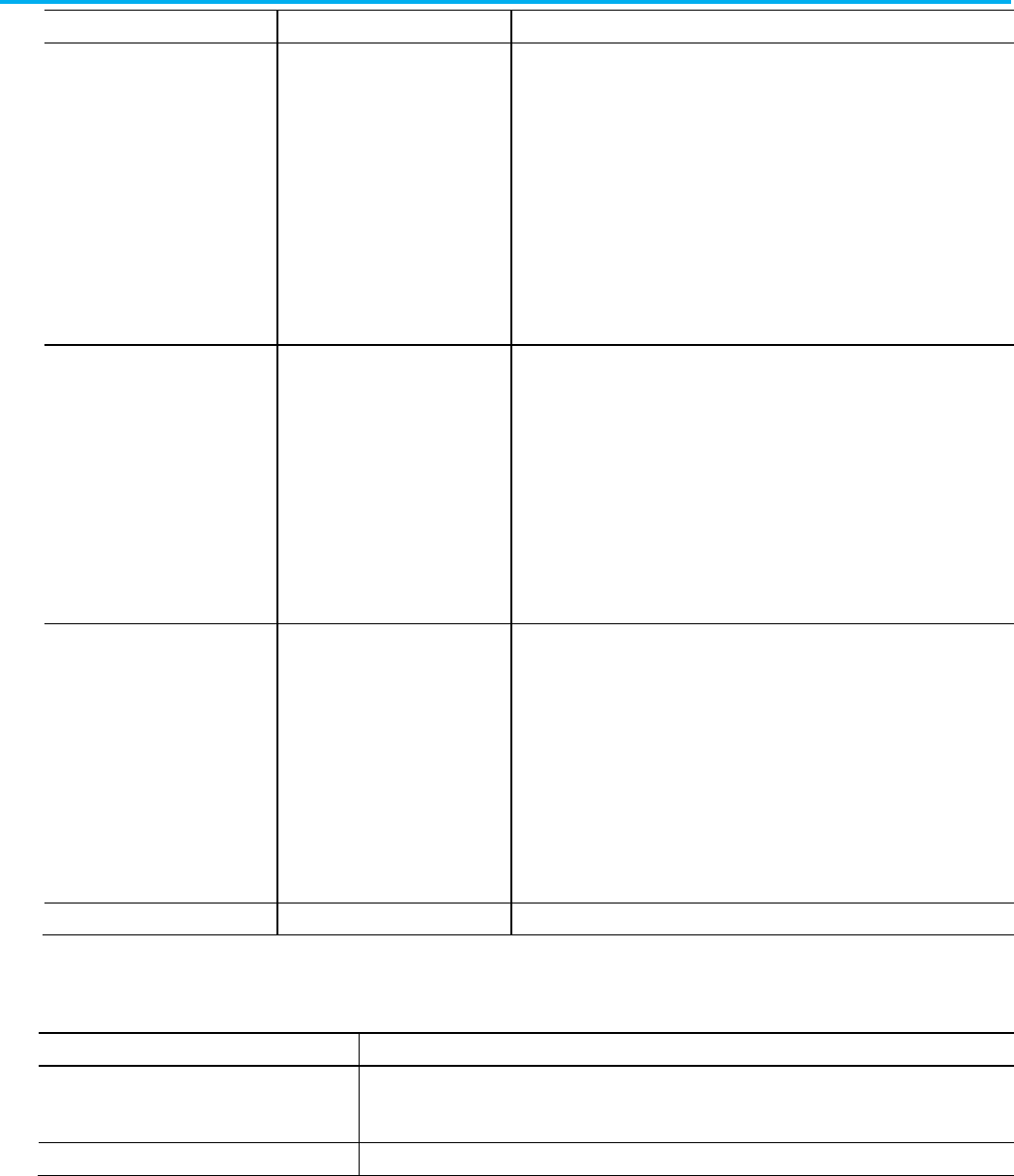

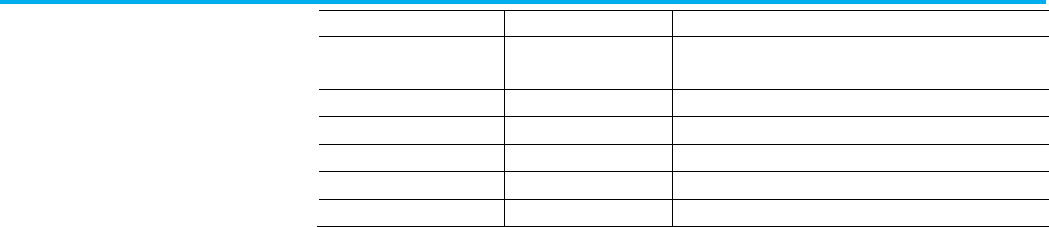

4. From the Tags lists, specify how to handle tag collisions.

IMPORTANT

When you import tags, the tags in the import file might have the same name as

the tags that are already in the project. This condition is a collision.

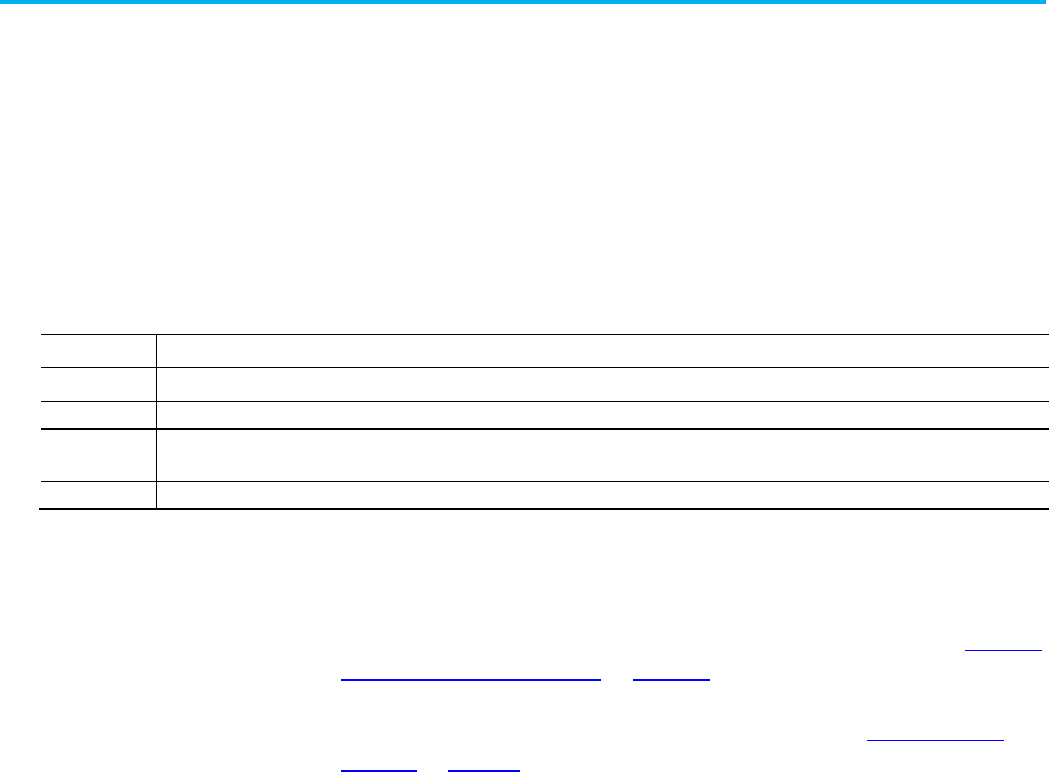

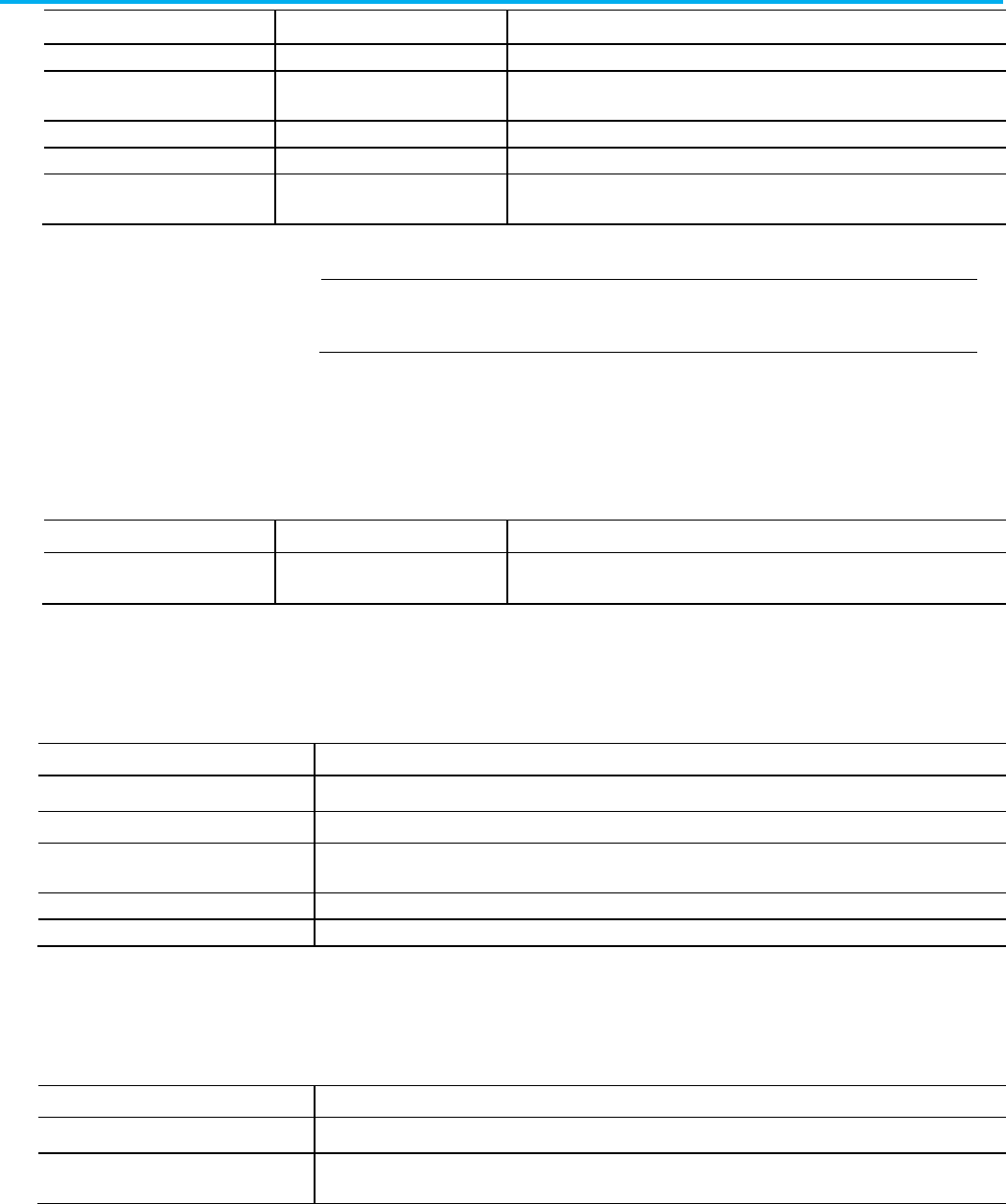

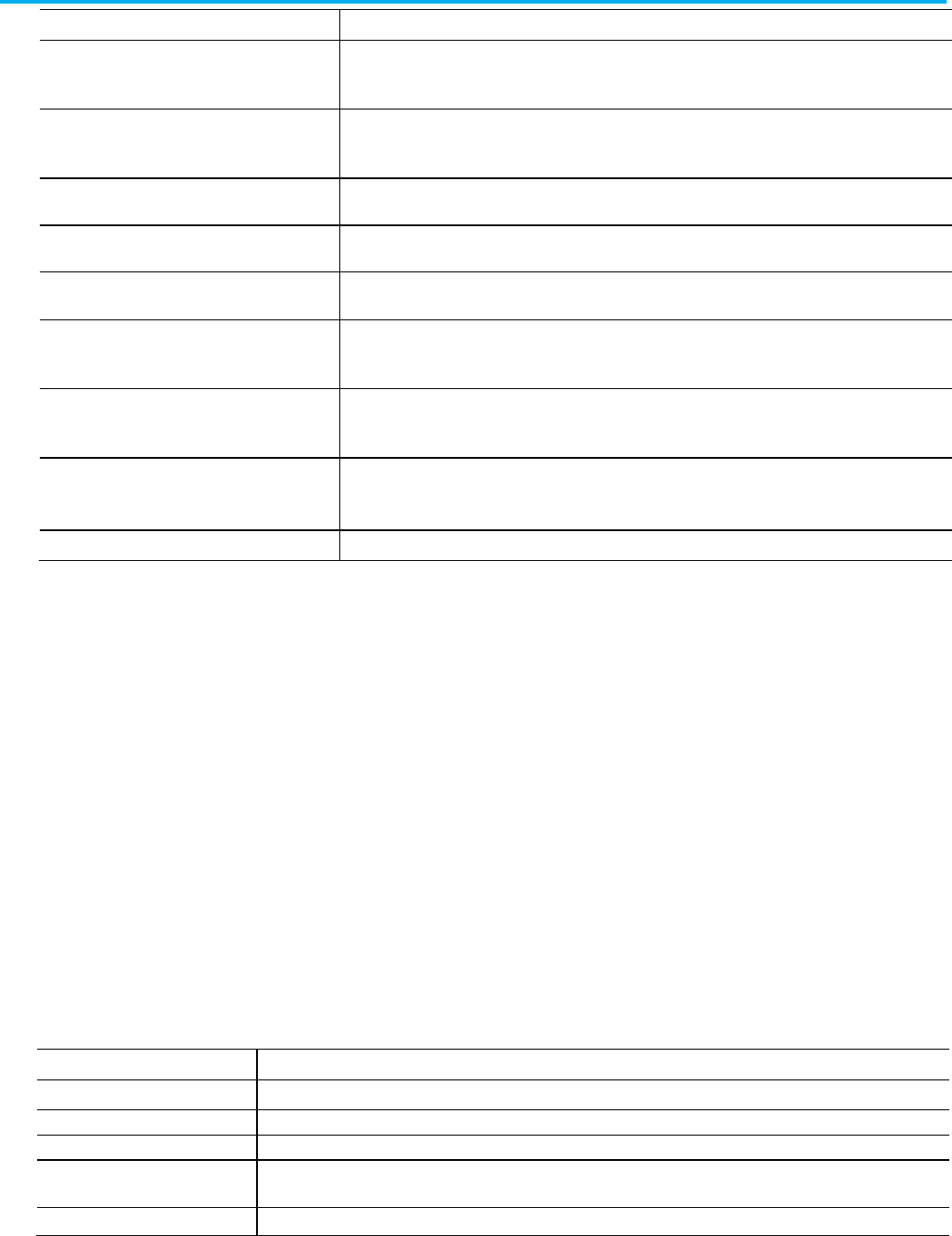

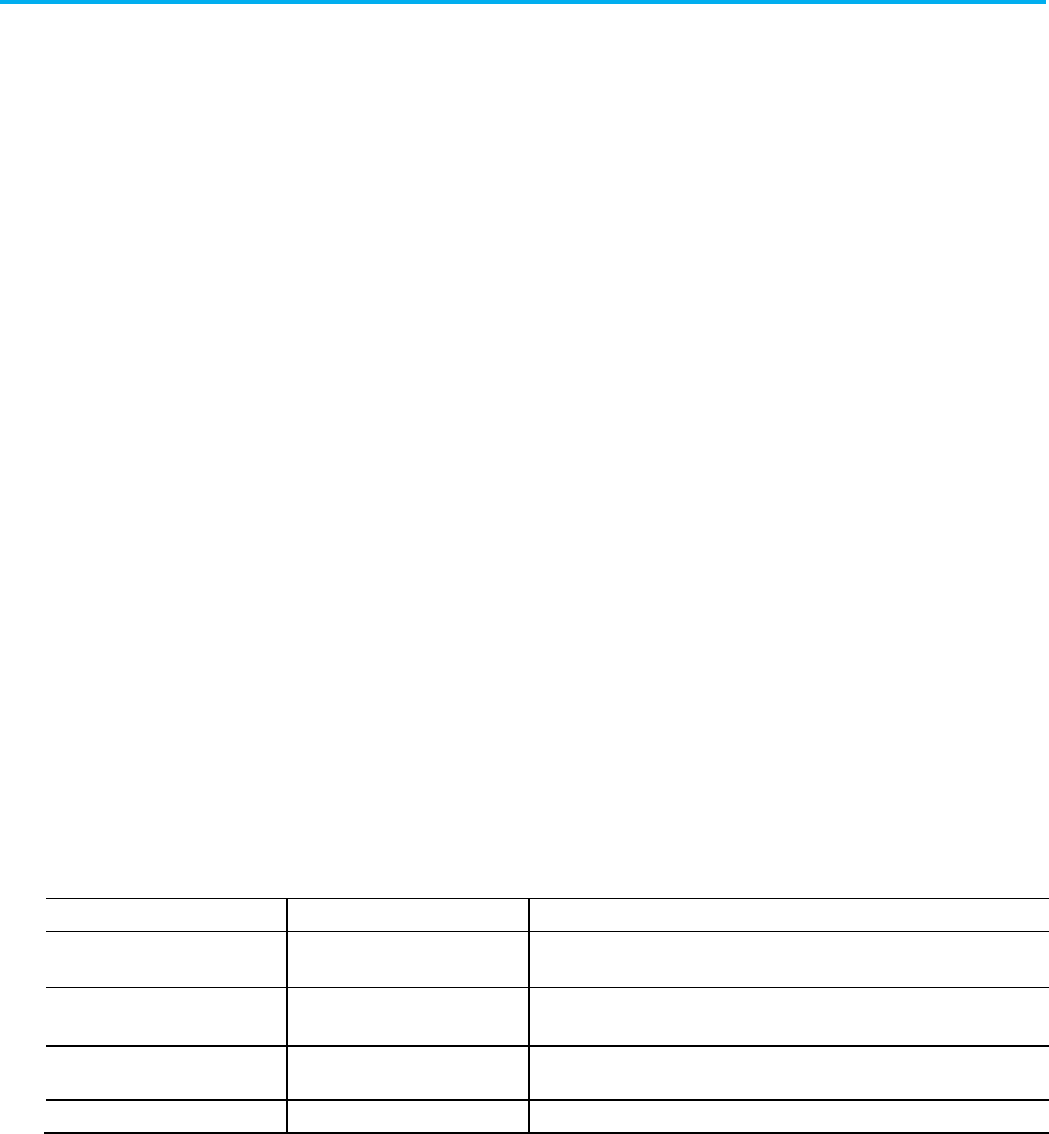

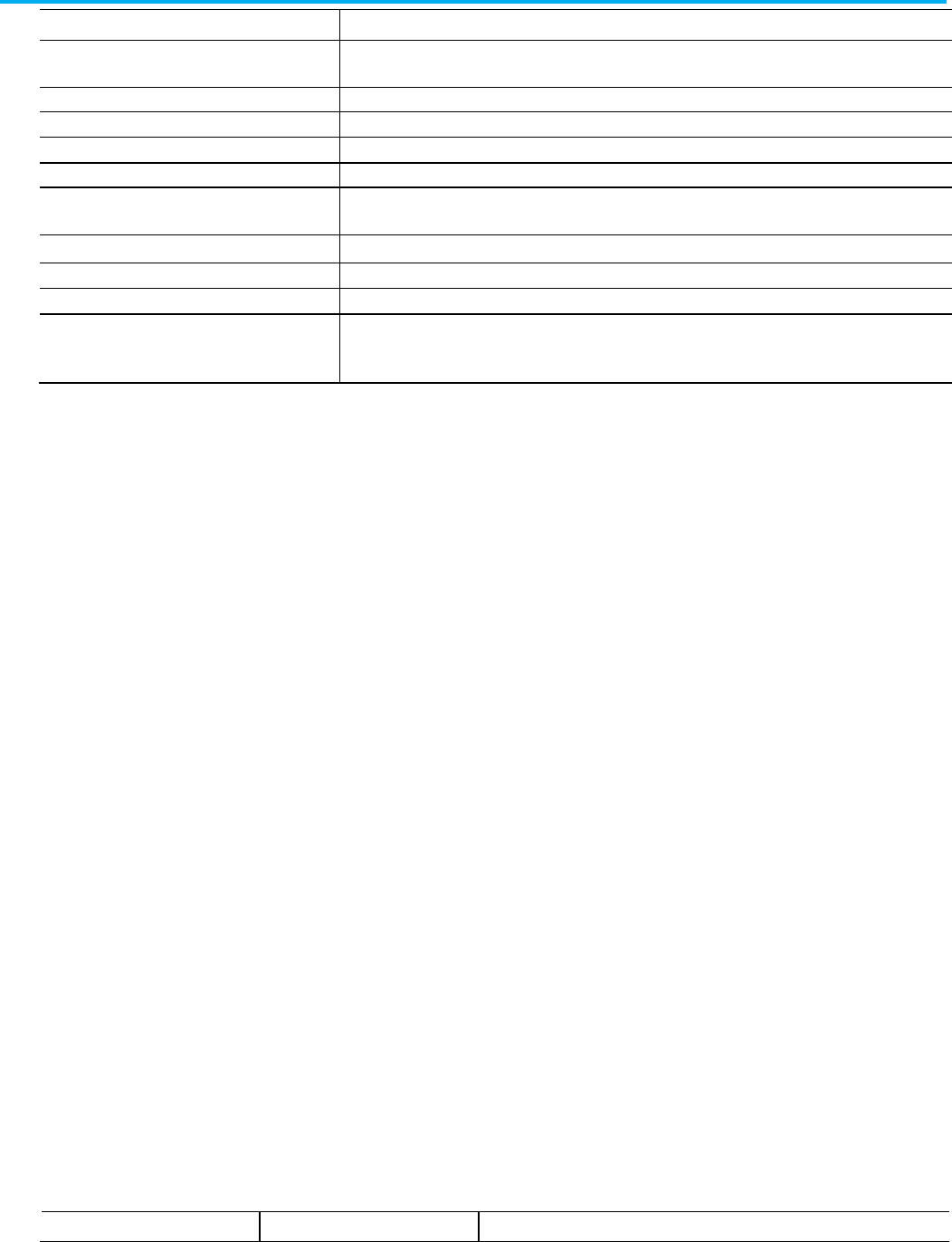

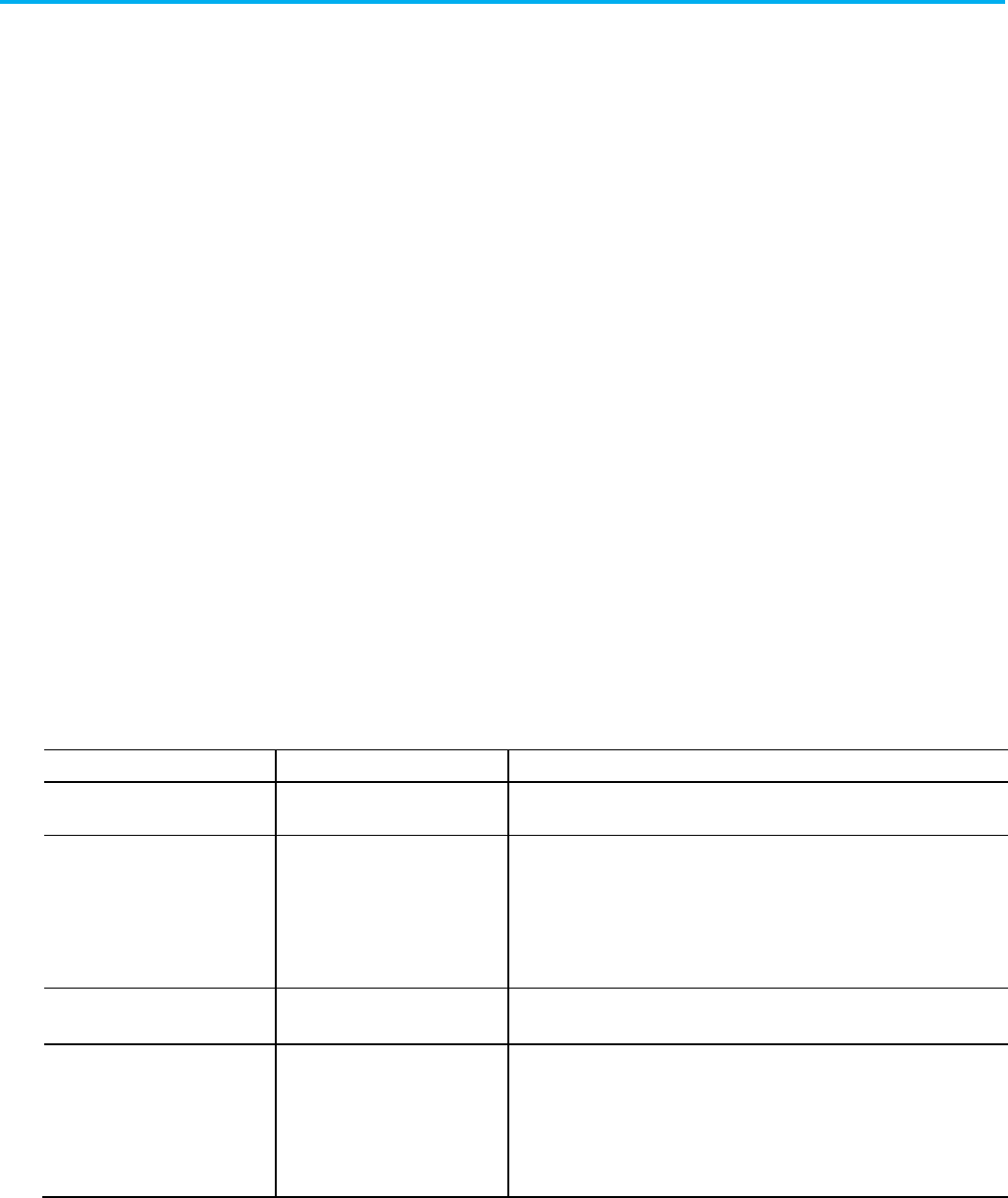

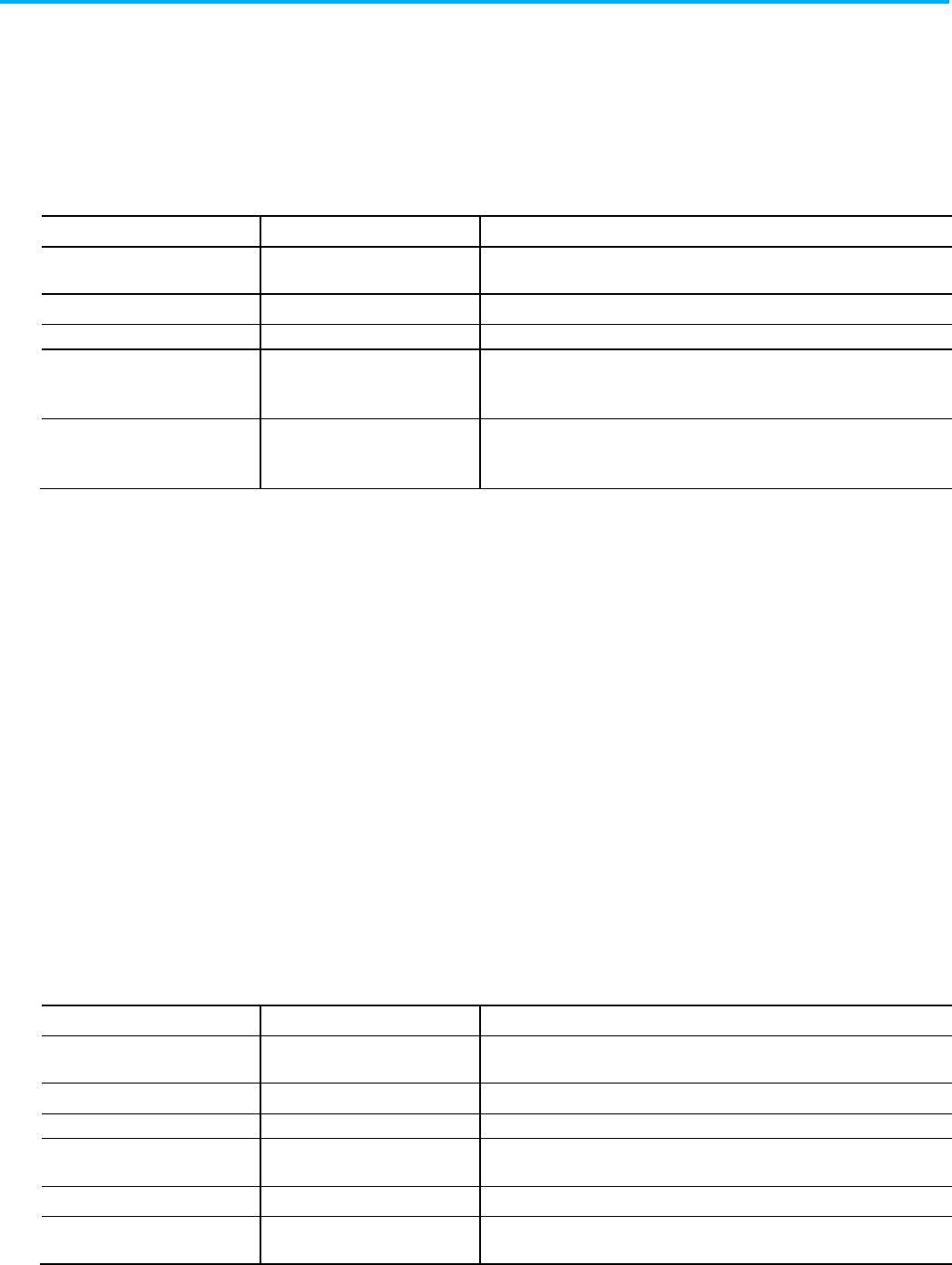

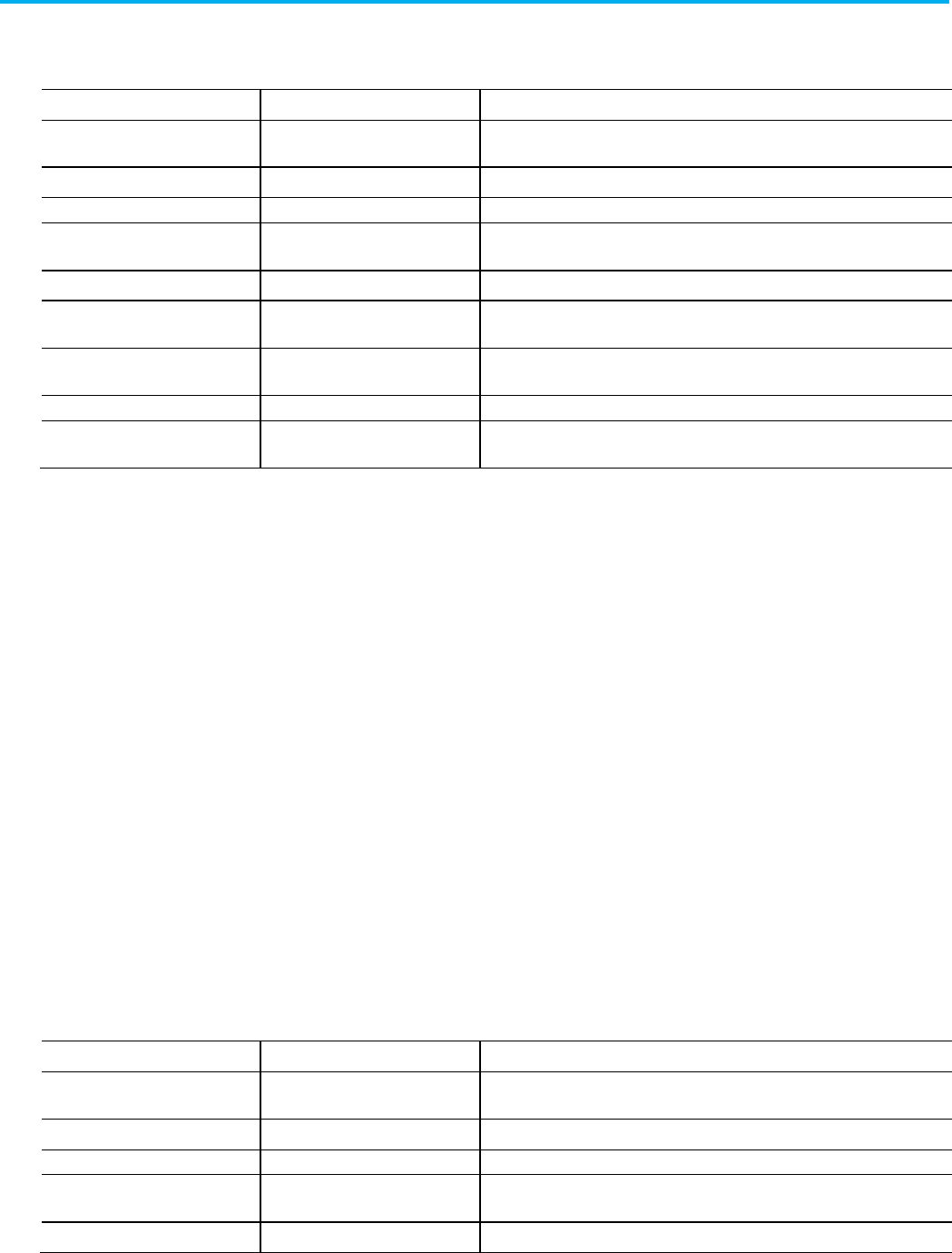

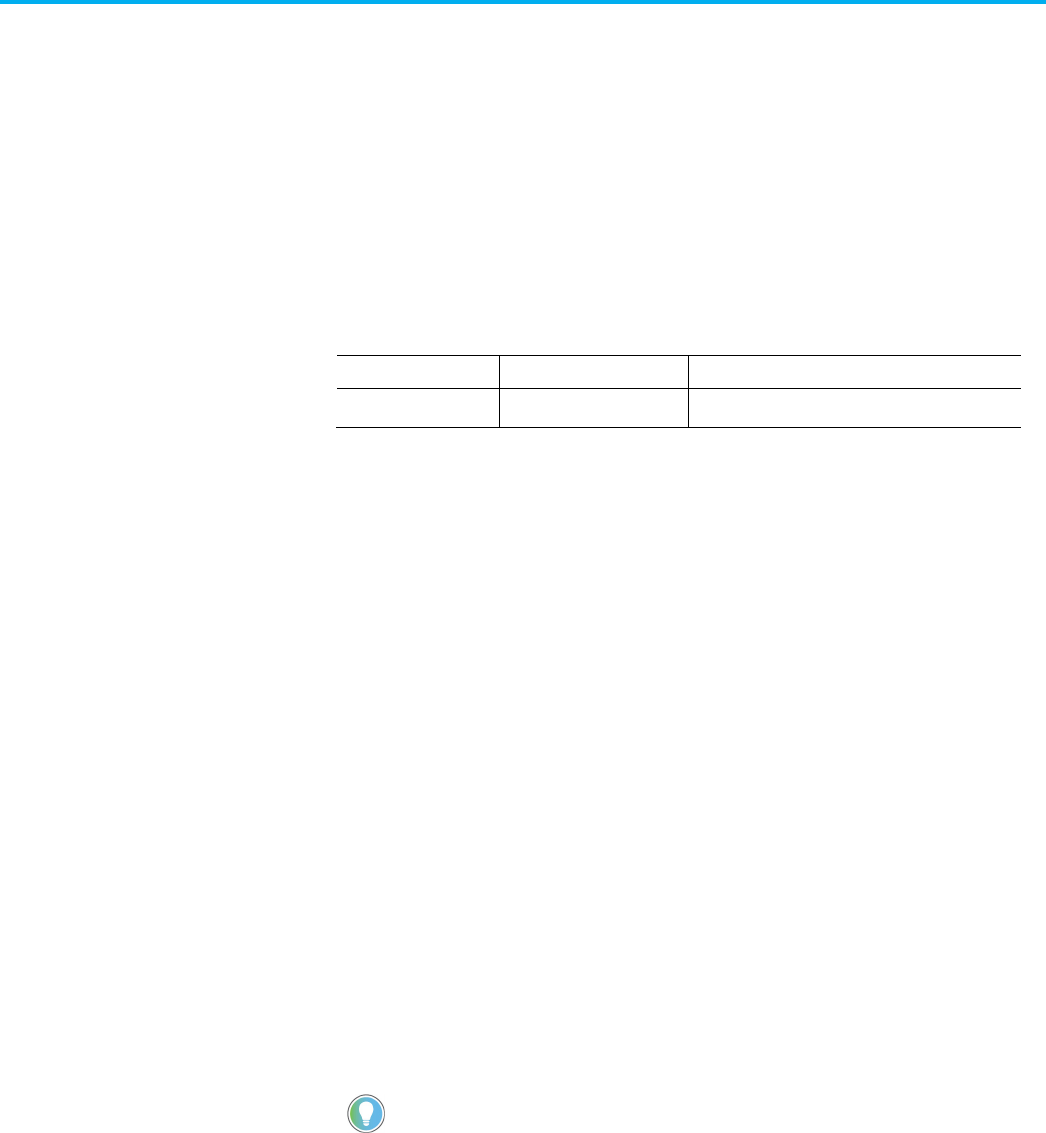

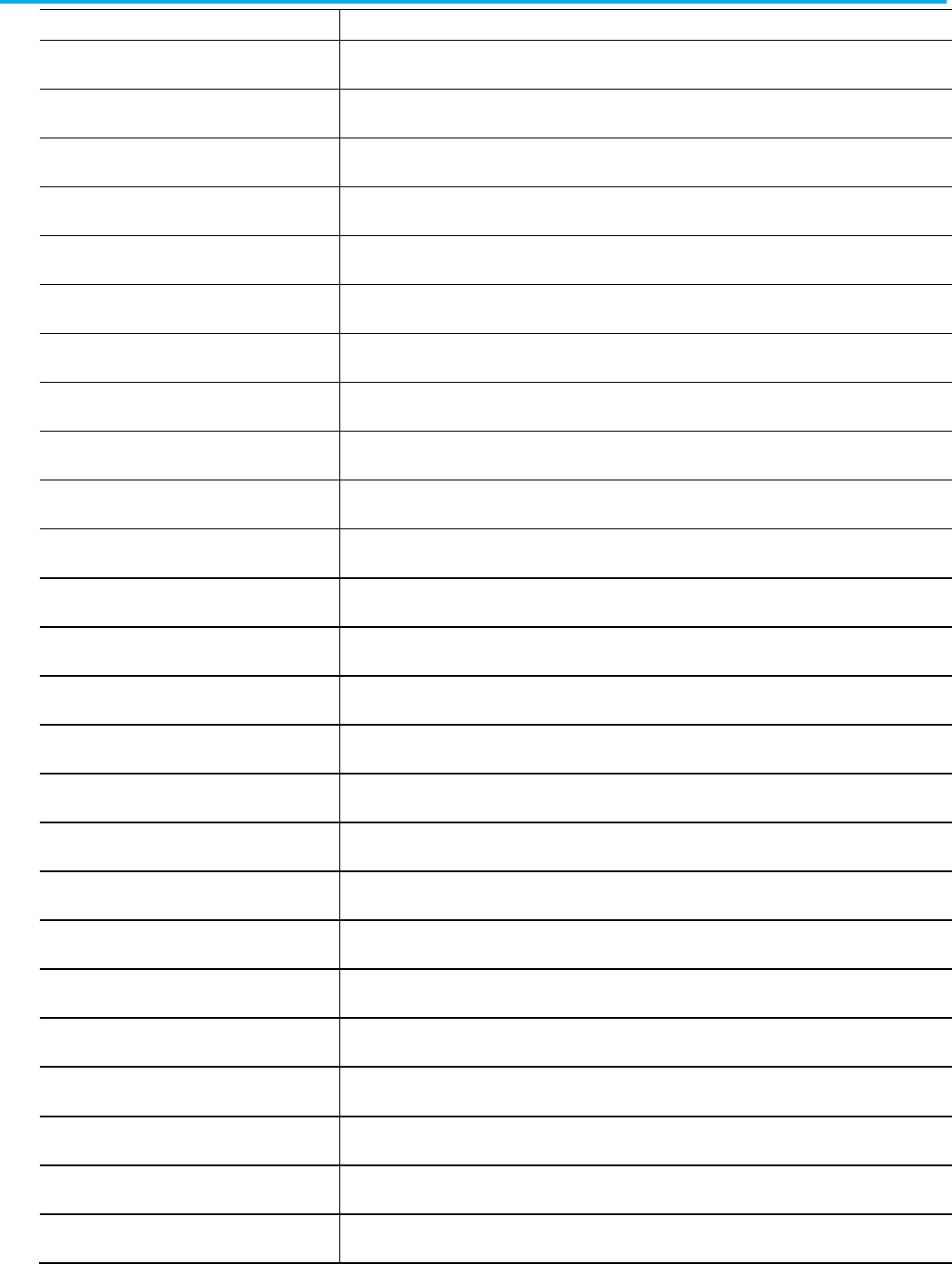

If you want to:

From the Tags menu select:

Replace tags in the project with tags from the import file, in

addition to adding any new tags from the import file

Create New Tags & Overwrite Existing Tags

Keep tags that are in the project and discard colliding tags in the

import file, in addition to adding any new tags from the import file

Create New Tags & Overwrite Existing Tags

Replace tags in the project with tags from the import file, but do

not add any new tags from the import file

Create New Tags & Overwrite Existing Tags

Chapter 1 Import and export files

Publication 1756-RM014B-EN-P - November 2023 35

IMPORTANT

If you delete tags from the .CSV or .TXT file and import the file, the process does

not delete the tags from the controller project. Use the programming software

to delete tags from the controller project.

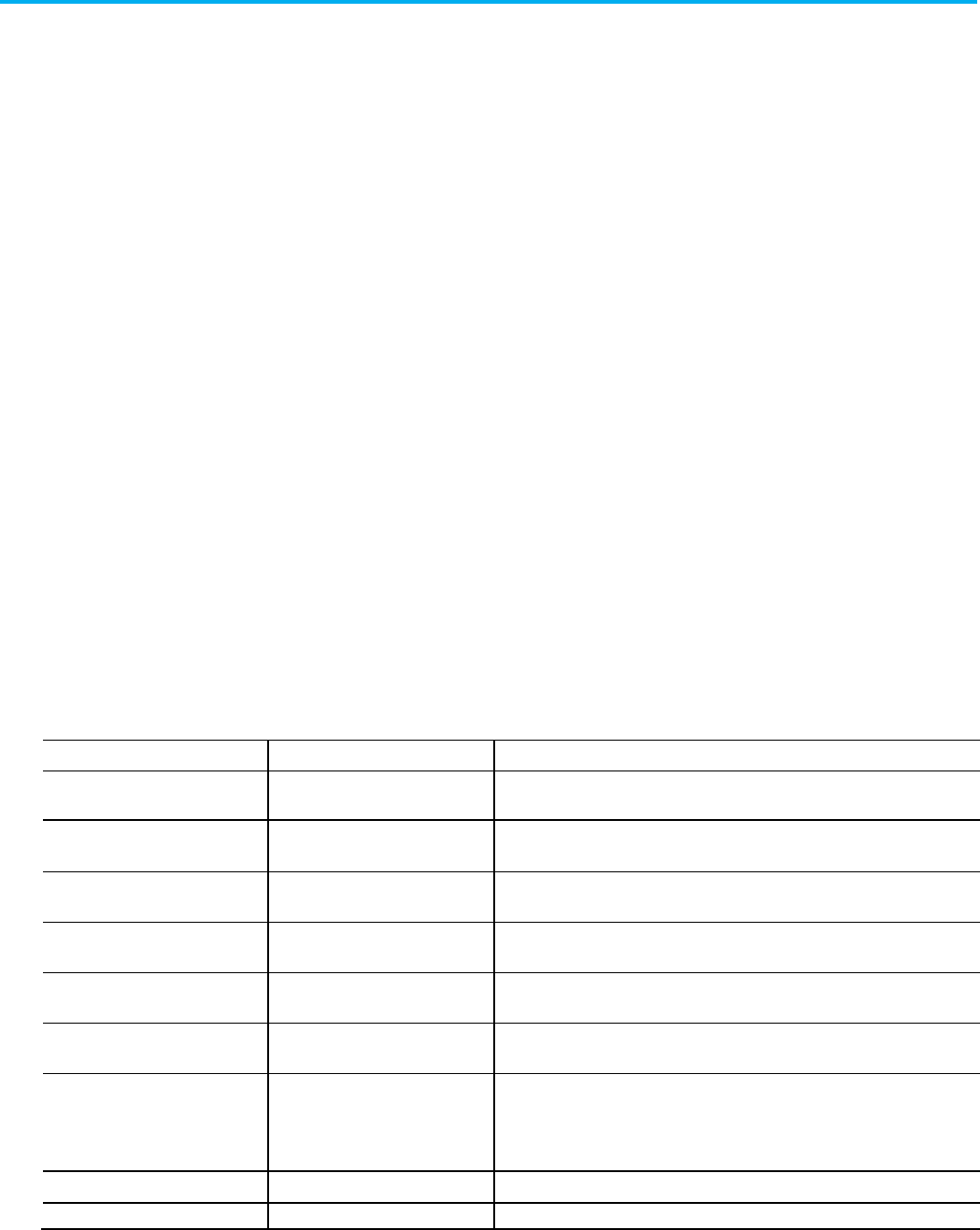

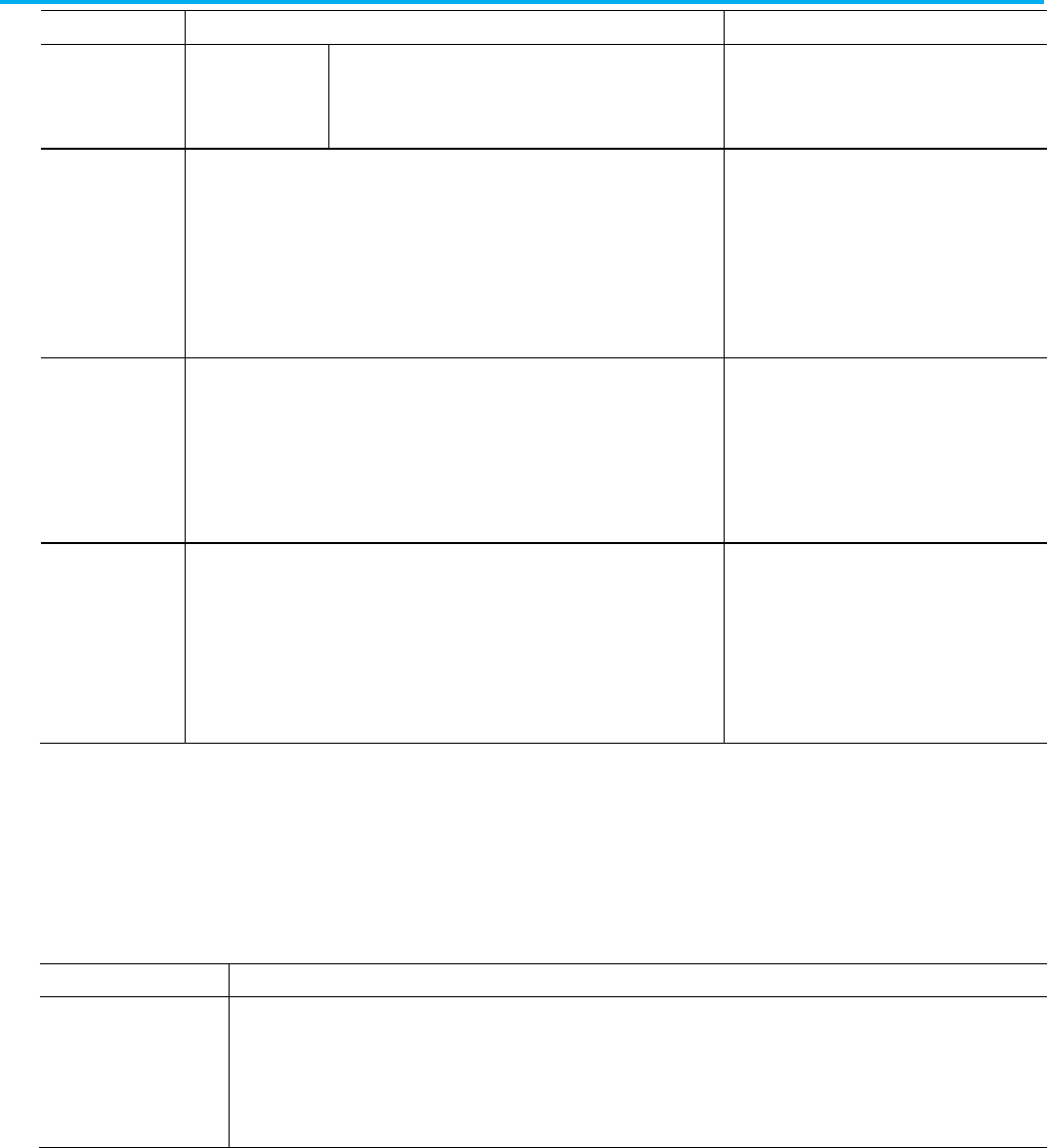

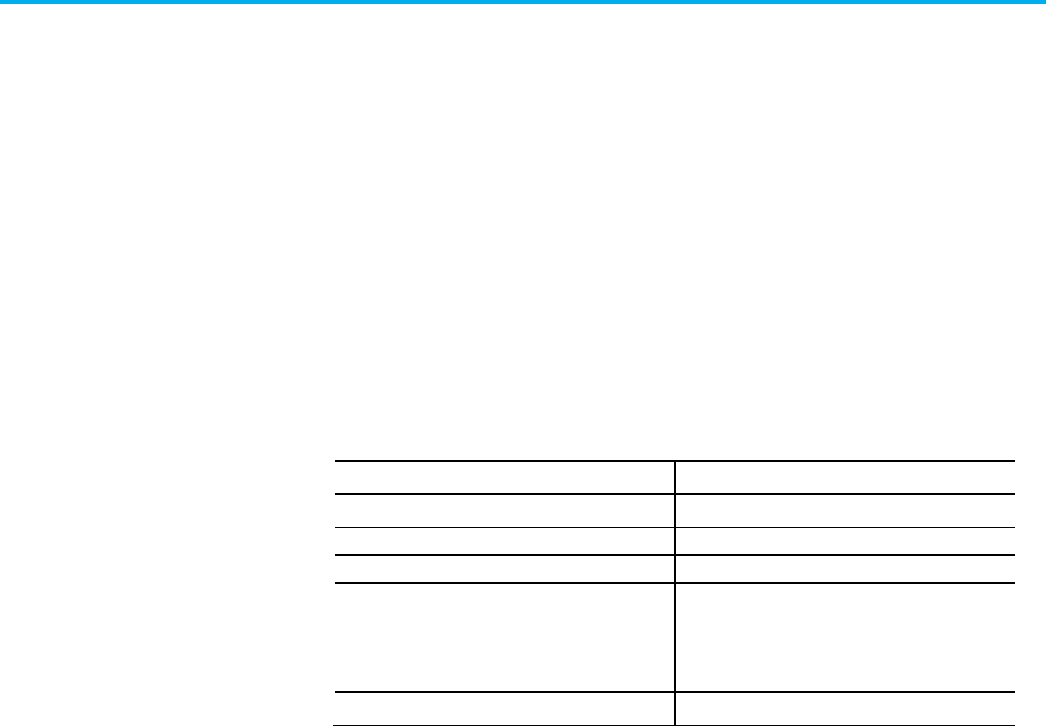

5. From the Logic Comments list, specify how to handle logic comment

collisions.

IMPORTANT

When you import logic comments, the possibility exists for the comments in the

import file to differ from the comments in the open project when both are

matched to the same logic.

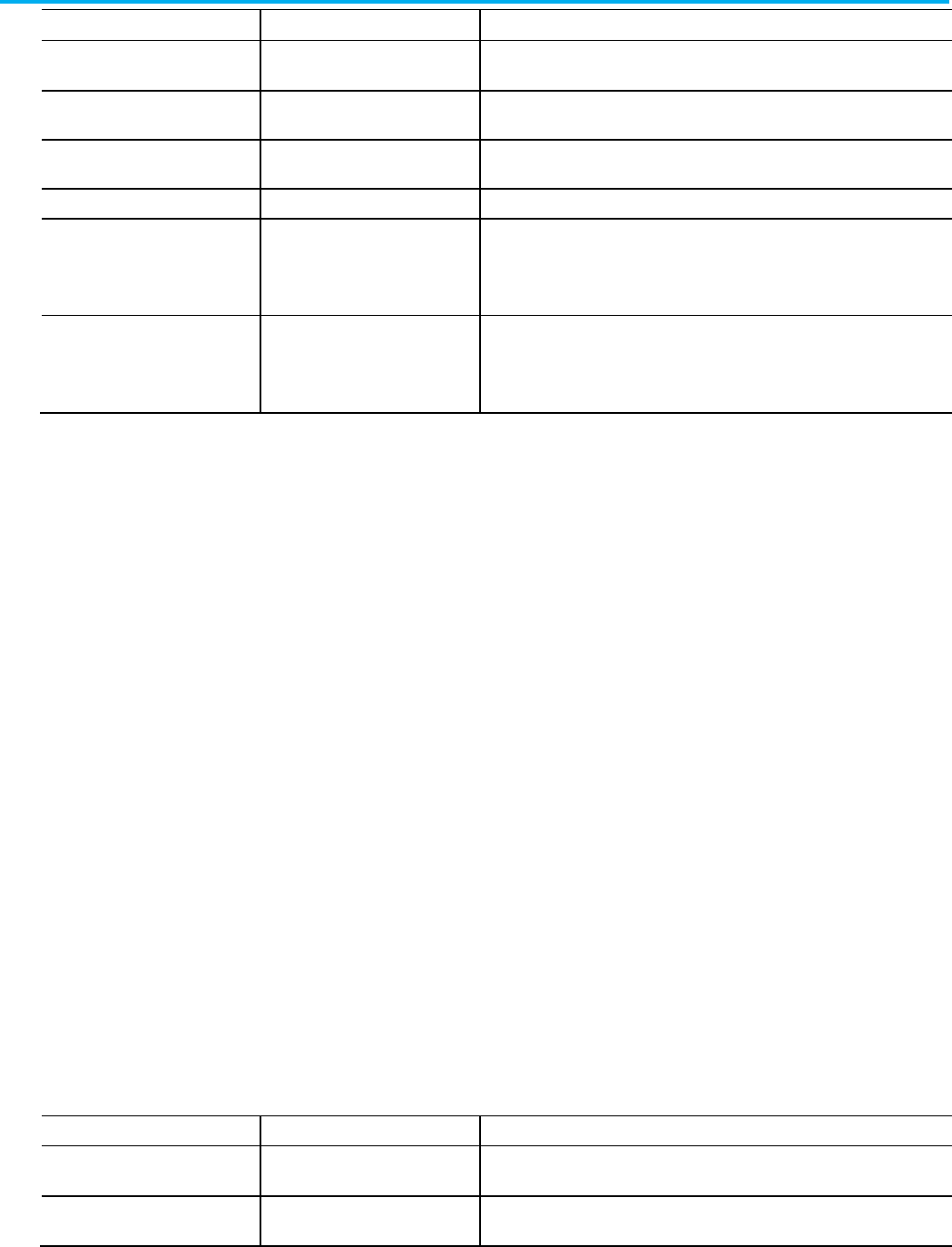

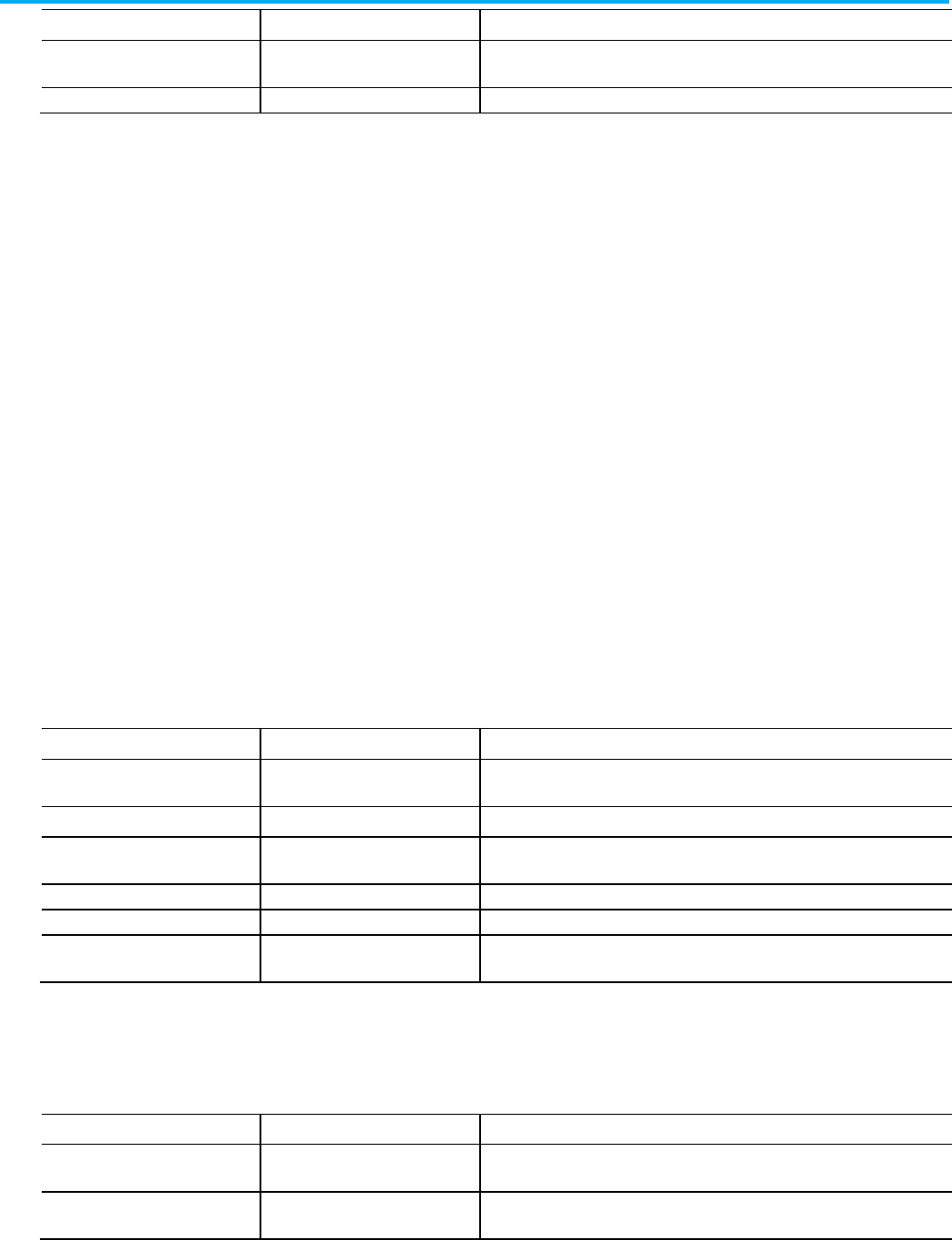

If you want to:

From the Logic Comments list select:

Replace comments in the project with

comments from the import file, in addition to

adding any new comments from the import file

Import New Comments & Overwrite Existing Comments

Keep comments that are in the project and

discard colliding comments in the import file,

in addition to adding any new comments from

the import file

Import New Comments & Preserve Existing Comments

Replace comments in the project with

comments from the import file, but do not add

any new comments from the import file

Skip New Comments & Overwrite Existing Comments

6. Choose how to match comments to logic and select Import.

If you want rung comments

applied to:

Then:

The next rung that has the instruction, as

specified in the Owning Element, as its last

instruction on the rung

Make sure that the

Leave the Match all ladder diagram

rung comments by rung only

check box is cleared.

This is the default and recommended option.

The Location element is ignored.

The rung number specified in the Location

element

Select the

Match all ladder diagram rung comments by

rung only

check box.

This overrides the default and recommended option.

The Owning Element is ignored.

IMPORTANT

If a .CSV file or .TXT file contains changes to tags, including aliases, when you

import the file that the project changes such that you cannot go online and

access a previously downloaded controller. You must first upload from or

download to the controller.

If you only modify comments or descriptions before you import a .CSV file or

.TXT file, you can go online with the controller.

Starting with version 20, you can configure how source-protected content is

exported in .L5K and .L5X files.

By default, source-protected content is now exported in an encrypted format

to prevent viewing or modifying components in the system. A check box

option on the Workstation Options dialog box enables Add-On Instructions

and routines to be exported in a readable, cleartext format if the source keys

for those components are present in the sk.dat file. This lets you modify

protected content in a third-party tool, such as an XML editor.

Export source-protected

logic

Chapter 1 Import and export files

36 Publication 1756-RM014B-EN-P - November 2023

IMPORTANT

You must enable your workstation for source protection to use the cleartext option on

the

Workstation Option

dialog box. Otherwise, the check box is not available and

source-protected content is exported in an encrypted format.

Perform a partial or full-project export in cleartext when these parameters are

available:

• Your workstation has source protection enabled.

• The Workstation Option dialog box (Always Encode Source

Protection Content On Export) is not selected.

• The sk. dat file has been specified and it contains the source key

(password) for the content. For details, see the Logix5000 Controllers

Security Programming Manual , publication 1756-PM016.

If any of these requirements are absent, the content is exported in an

encrypted format.

Use the same procedure for partial exporting a component or a full project in

readable text. Use these steps.

1. Open a project in the Logix Designer application that contains the

content that you want to export.

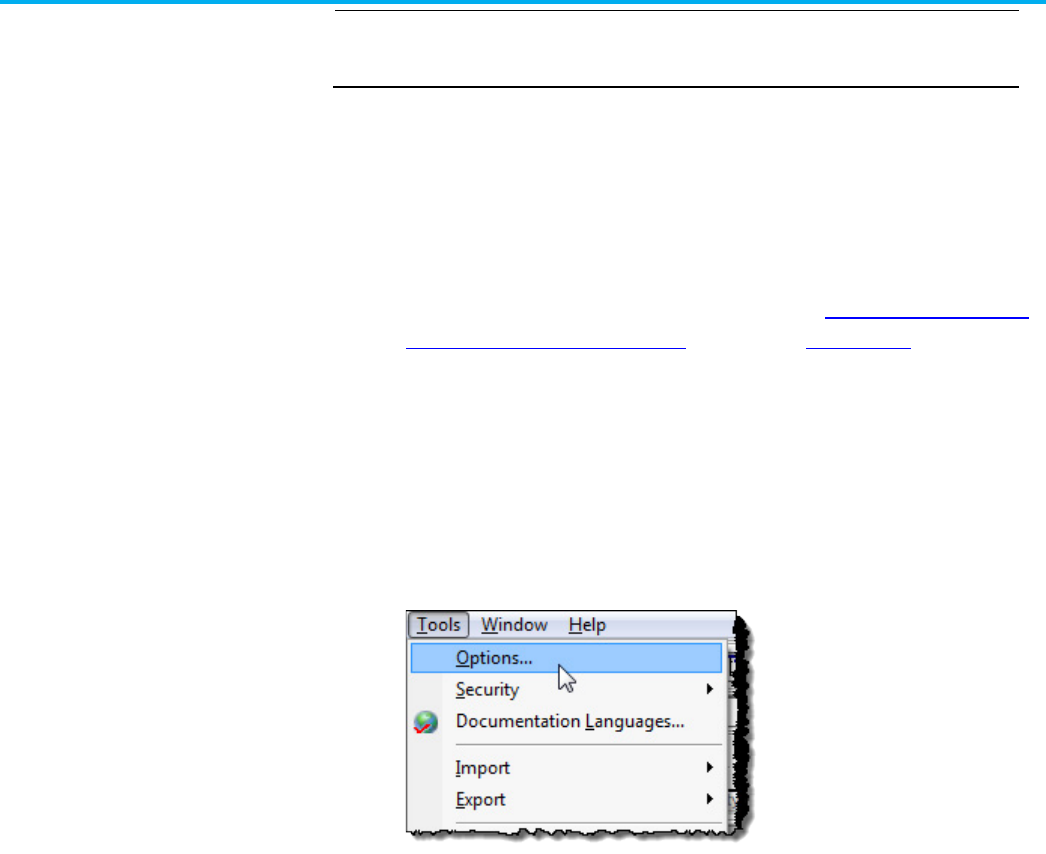

2. On the Menu bar, select Tools > Options.

Export in a Cleartext

Format

Chapter 1 Import and export files

Publication 1756-RM014B-EN-P - November 2023 37

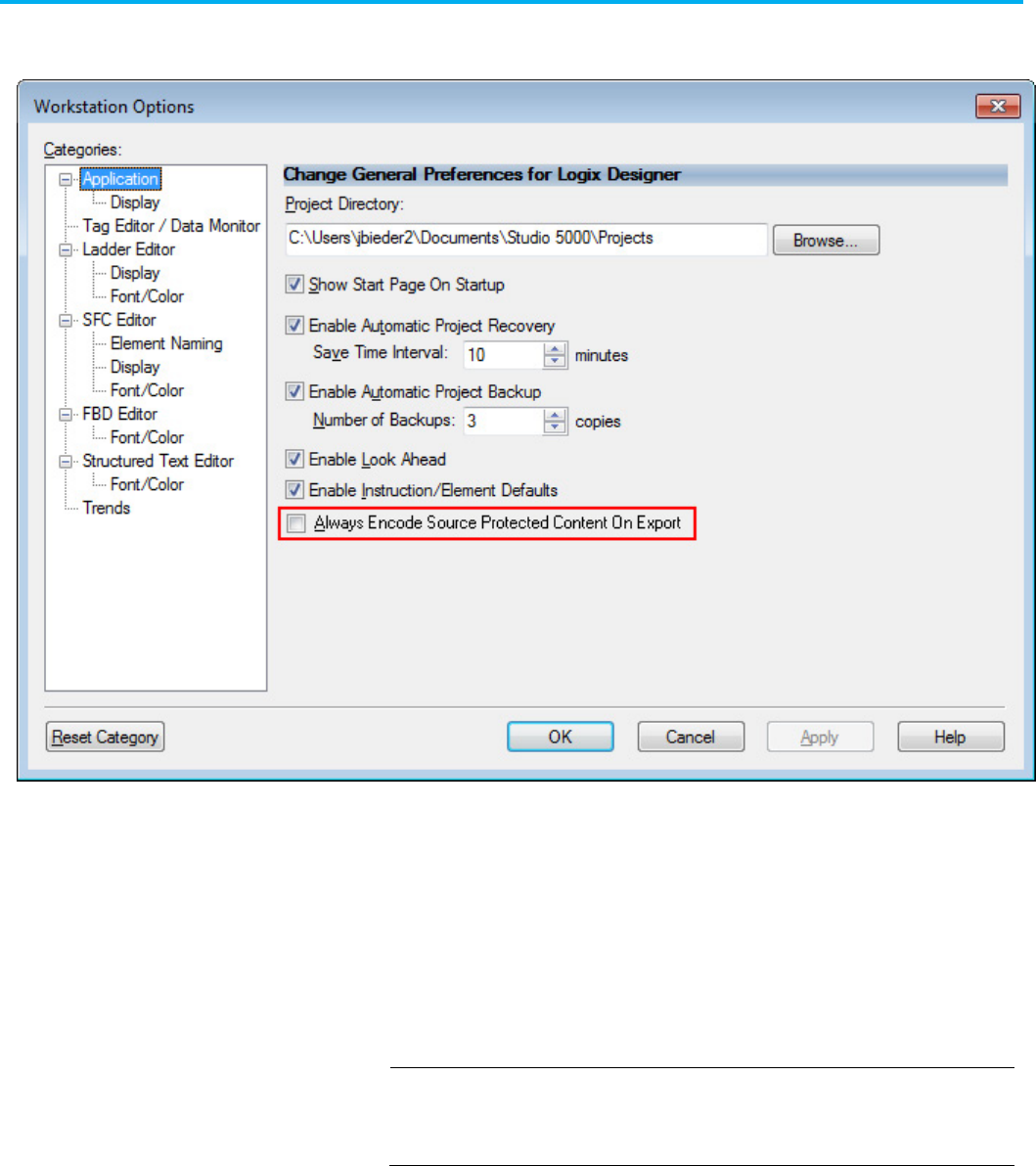

The Workstation Options dialog box opens with the export check box

option if your personal computer is enabled for source protection.

3. Clear the Always Encode Source Protected Content On Export check

box.

There is a similar check box on the Save As and Export component

dialog boxes that you must clear to export in cleartext from those

dialog boxes.

If you select the Always Encode Source Protected Content On Export

check box on the Workstation Options dialog box, the application

always exports source-protected content in an encrypted format, even

when source keys for the content are present.

IMPORTANT

You cannot copy source-protected content from version 21 of the application

and paste into earlier software versions. The pasting function is disabled in

previous software versions when source-protected content is placed on the

clipboard.

4. Select OK.

5. Take one of these actions:

• To export a component, right-click the component and choose

Export Routine. The component Export dialog box opens. Clear the

Encode Source Protected Content check box. Select the Export

button.

Chapter 1 Import and export files

38 Publication 1756-RM014B-EN-P - November 2023

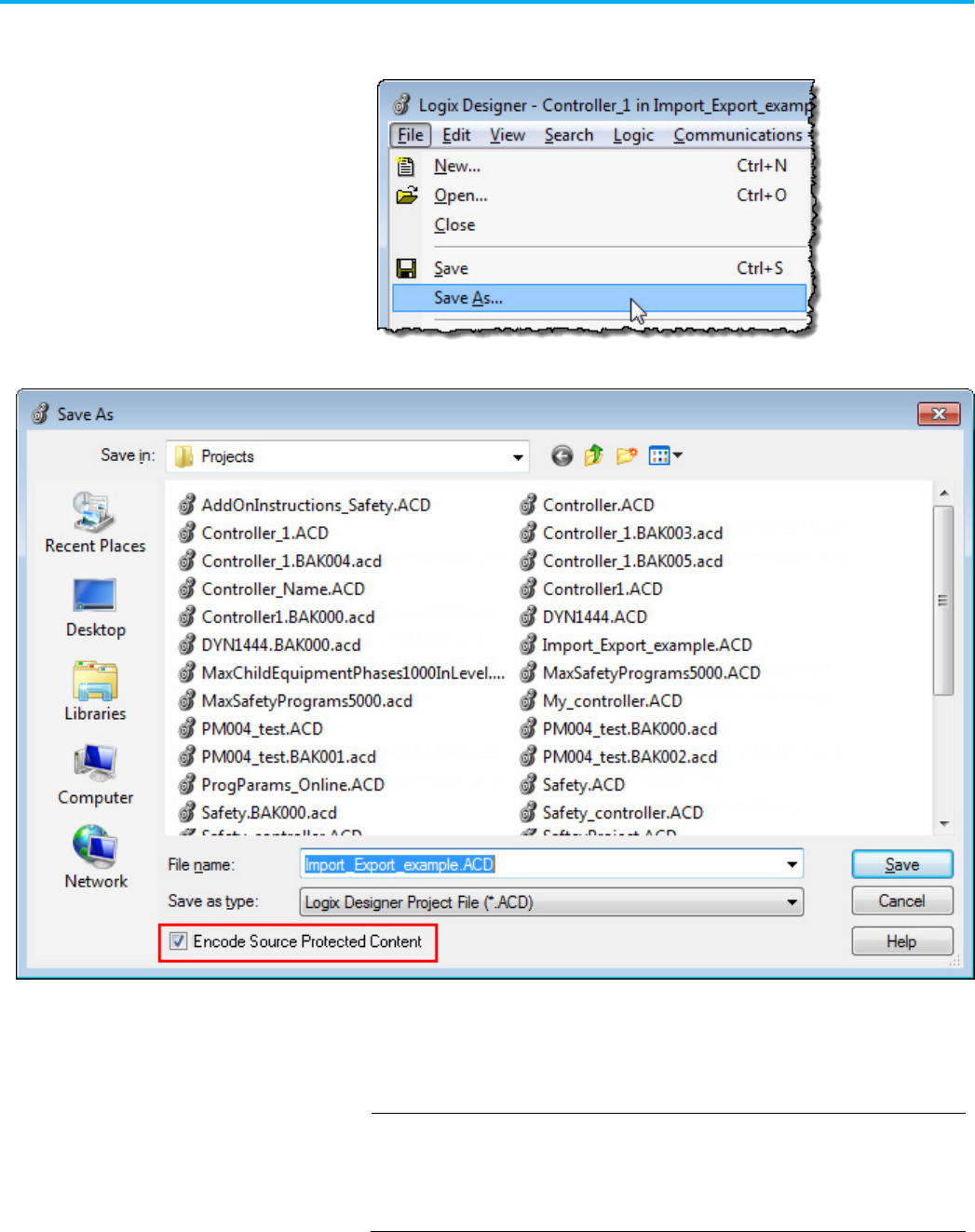

• To save data for exporting as an .L5X or .L5K file, proceed to step 6.

6. On the Menu bar, select File > Save As.

The Save As dialog box opens.

7. From the Save as type list, select the .L5K or .L5X option, depending on

your file type.

The Encode Source Protected Content check box is available when you

choose the .L5K or .L5X option.

IMPORTANT

The

Encode Source Protected Content

check box is only enabled when the

Always Encode Source Protected Content on Export

check box in the

Workstation Options

dialog box is cleared.

The

Encode Source Protected Content

check box also appears on the

component dialog box.

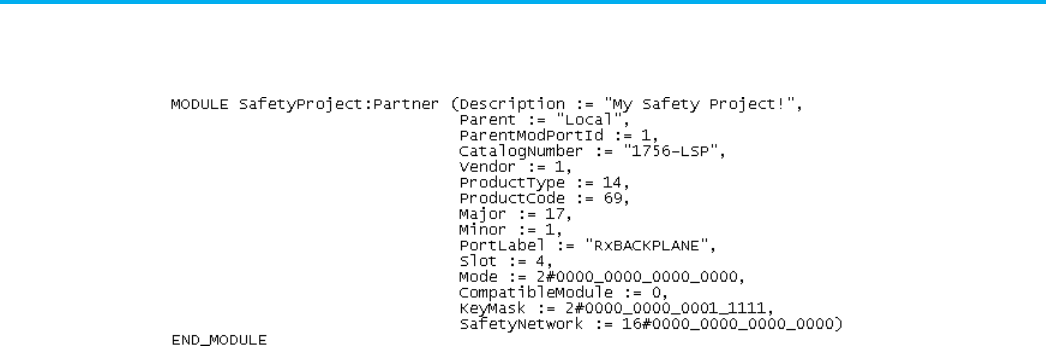

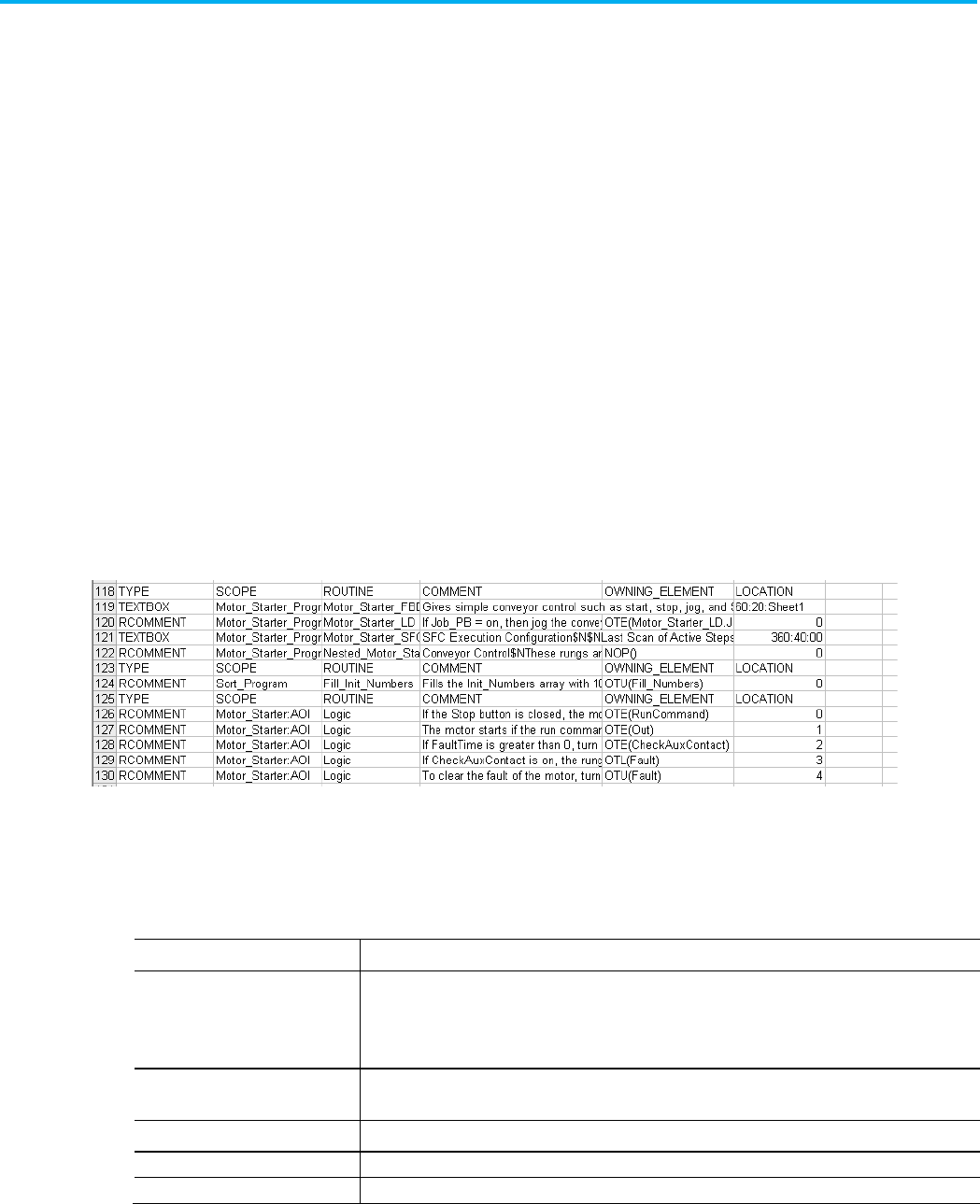

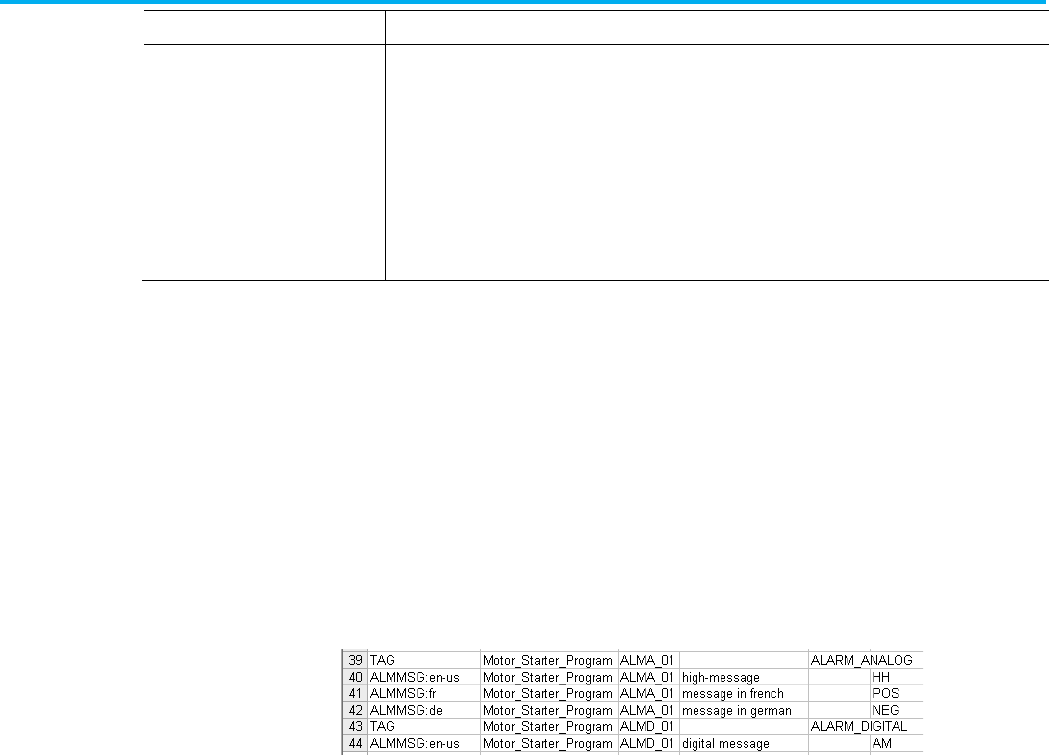

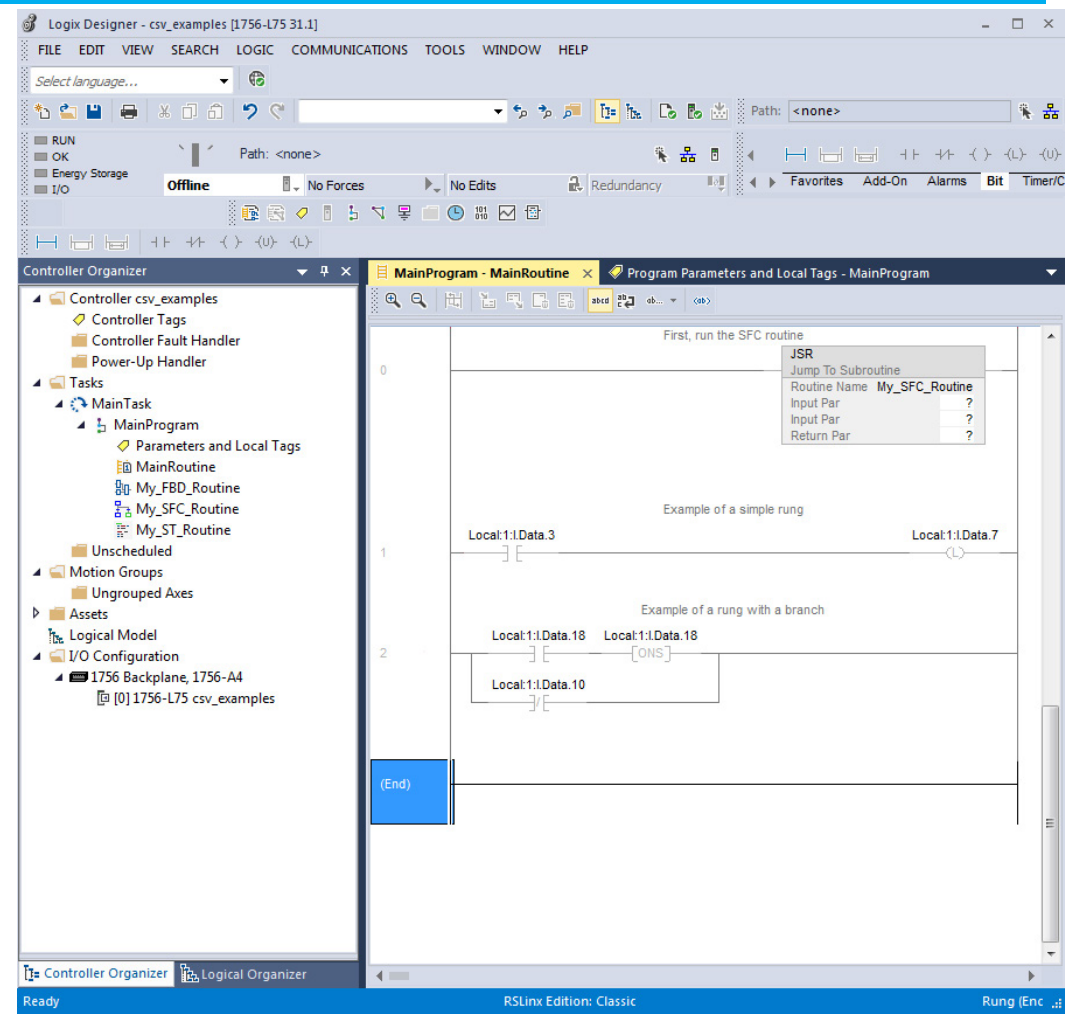

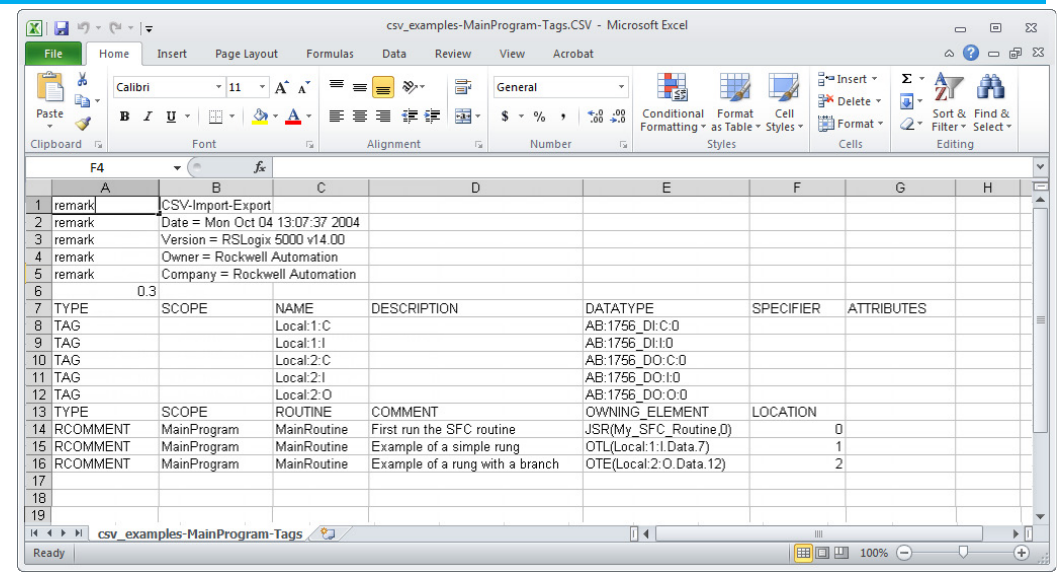

8. Clear Encode Source Protected Content check box to export content in